Waste gas treatment method for silencer, dust-extraction device and engineering machinery motor

A technology for construction machinery and noise reduction devices, which is applied in the fields of dust removal devices, exhaust gas treatment, and silencers. It can solve problems such as the impact of noise reduction effects, the impact on the environment, and the increase in dust accumulation in the silencer, so as to achieve environmental protection and reduce particle content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

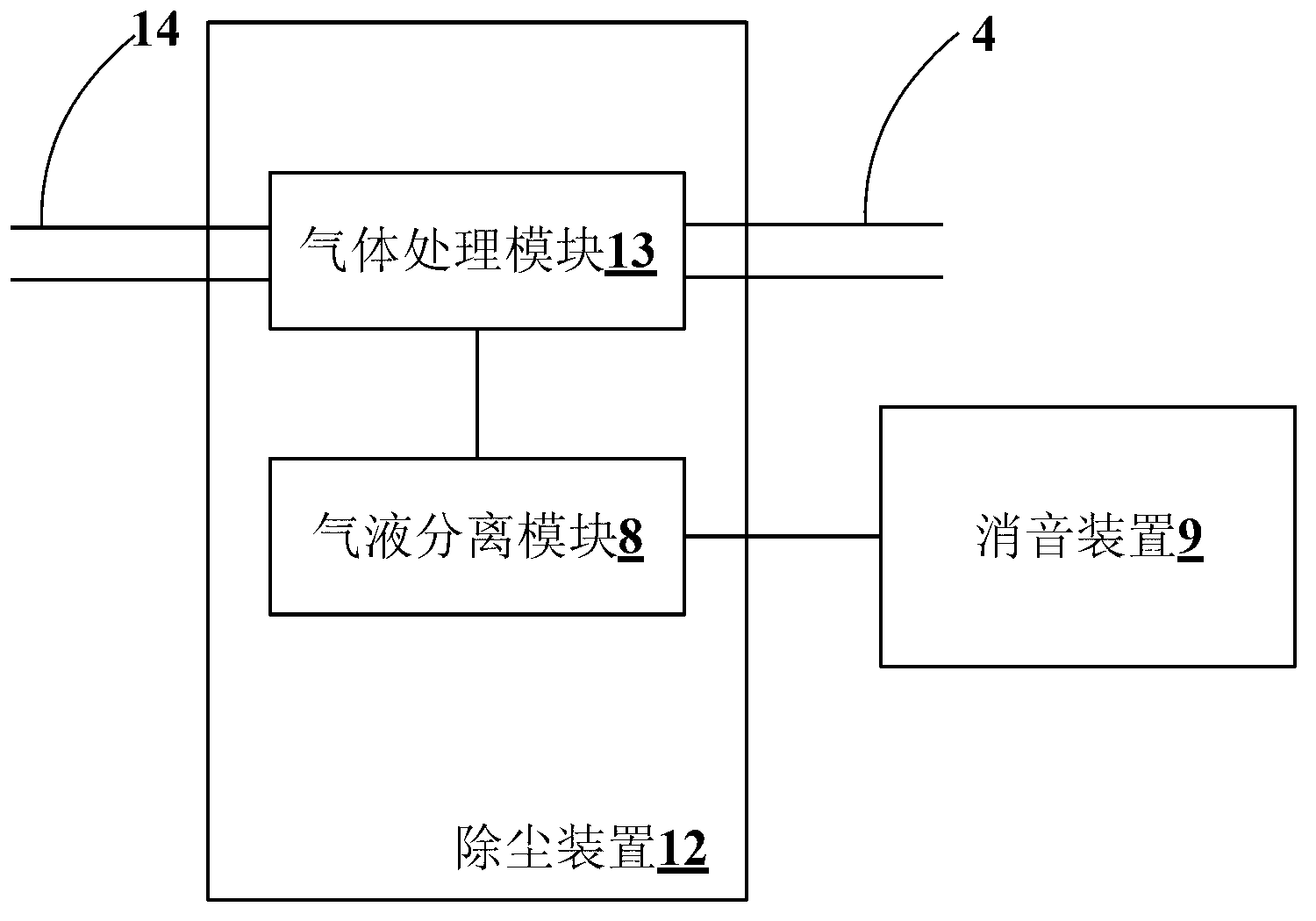

[0041] refer to figure 1 . The muffler of this embodiment is used for exhaust gas treatment of engineering machinery engines, including dust removal device 12 and noise reduction device 9, dust removal device 12 includes a gas treatment module 13 and a gas-liquid separation module 8 based on the Venturi effect; dust removal device 12 and noise reduction device 9 pass through The connection is as follows: the gas processing module 13, the gas-liquid separation module 8 and the muffler 9 are connected sequentially.

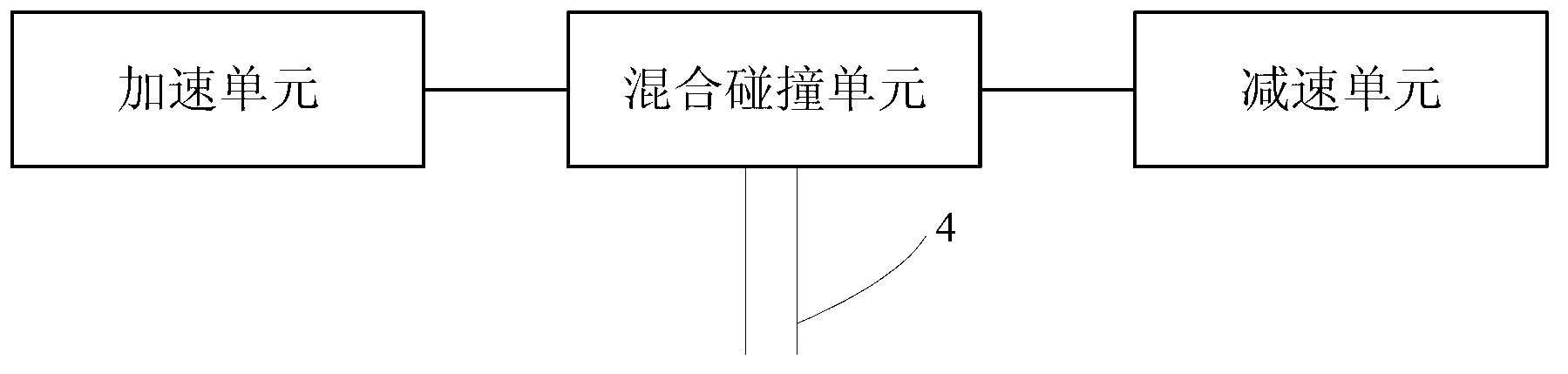

[0042] refer to figure 2 Specifically, the gas treatment module 13 includes an acceleration unit, a mixing and collision unit, and a deceleration unit connected in sequence; the mixing and collision unit is also connected to a water spray pipe 4 .

[0043] In this embodiment, the exhaust gas from the engineering machinery engine enters the gas treatment module 13 through the pipeline 14. After the exhaust gas (also called "dusty gas") enters the acceleration unit...

no. 2 example

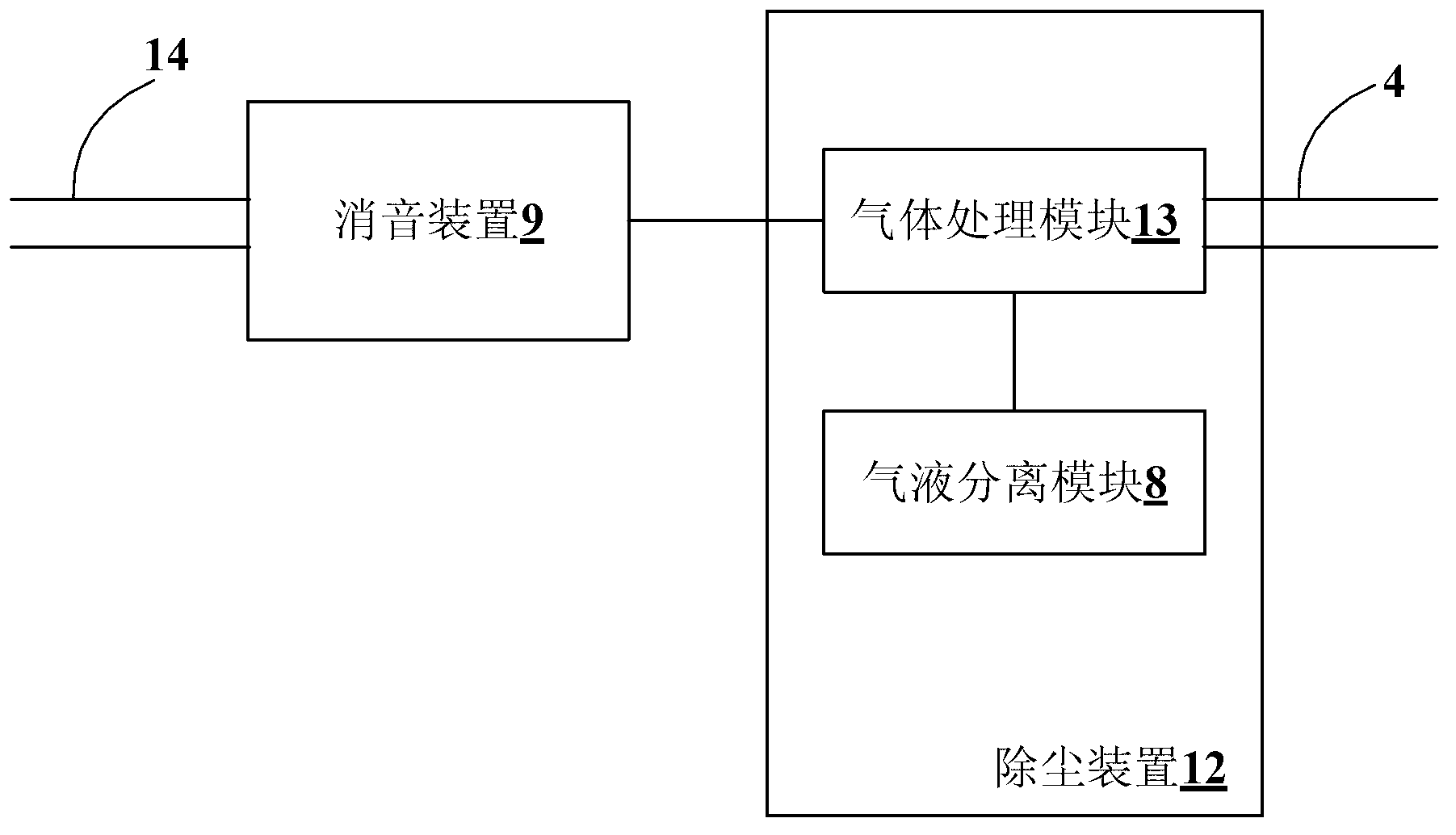

[0046] refer to image 3 .

[0047] The muffler of this embodiment is used for exhaust gas treatment of engineering machinery engines, including a dust removal device 12 and a noise reduction device 9, and the dust removal device 12 includes a gas processing module 13 and a gas-liquid separation module 8 based on the Venturi effect; wherein, the gas processing module 13 is also connected to There is a water spray pipe 4; and the muffler 9, the gas treatment module 13 and the gas-liquid separation module 8 are sequentially connected.

[0048] Similar to the first embodiment, specifically, the gas treatment module 13 includes an acceleration unit, a mixing collision unit and a deceleration unit connected in sequence; the mixing collision unit is also connected with a water spray pipe 4 .

[0049]In this embodiment, the exhaust gas from the engineering machinery engine enters the muffler device 9 through the pipeline 14 , and the exhaust gas (also called "dusty gas") after muffl...

no. 3 example

[0053] refer to Figure 4 . In this embodiment, an excavator engine is taken as an example for illustration.

[0054] This embodiment includes engine exhaust manifold seat 1, engine exhaust outlet pipe 2, venturi tube 3 (corresponding to "acceleration unit"), water spray pipe 4, throat pipe 5 (corresponding to "mixing and collision unit"), Diffusion pipe 6 (corresponding to "deceleration unit"), air pipe 7, gas-liquid separation device 8, muffler device 9, exhaust pipe 10, sewage pipe 11. The Venturi tube 3 is a generally tapered tube with a narrow mouth at one end and a wide mouth at the other end. Gas enters from the wide mouth at low speed and blows out from the narrow mouth at high speed.

[0055] The specific connection relationship is that the inlet end of the throat is connected with the narrow mouth end of the Venturi tube 3; Connected to the first end of the air pipe 7, the second end of the air pipe 7 extends into the gas-liquid separation module 8; the water spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com