Ageing-resisting anti-abrasion ceramic composite material special for hydraulic architecture

A ceramic composite material and hydraulic construction technology, which is applied in the anti-abrasion ceramic composite material and special anti-aging field of hydraulic construction, to achieve the effect of high material strength, strong toughness, increased strength and anti-abrasion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

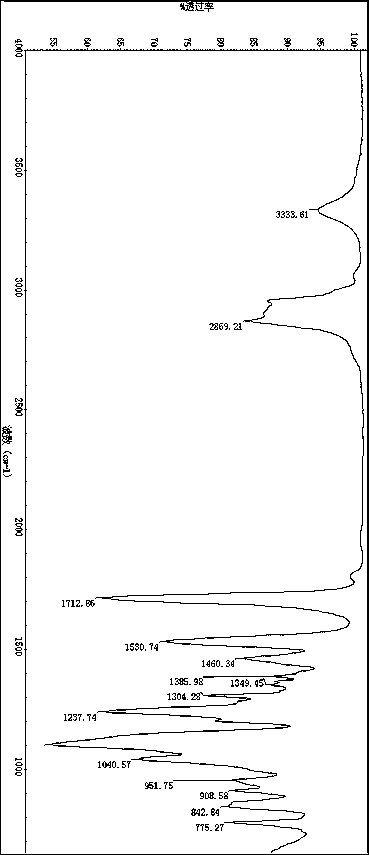

Method used

Image

Examples

Embodiment 1

[0035] The preparation of an anti-aging and abrasion-resistant composite material for hydraulic construction comprises the following steps:

[0036] Add 88.89g IPDI to the reaction vessel and pass into nitrogen protection, add 80g PEG400 dropwise to the reaction vessel, heat up to 30°C for reaction under stirring conditions, and continue stirring for 6h to synthesize the isocyanate group-terminated polyurethane prepolymer; The isocyanate-terminated polyurethane prepolymer continues to be protected by nitrogen gas, and the temperature is controlled at 25°C. Add 29.63g of glycidol dropwise to the reaction vessel, stir for 1 hour after the dropwise addition, and then raise the temperature to 80°C for 1 hour to prepare a polyurethane epoxy resin Standby; take 50g of polyurethane epoxy resin, 100g of unmodified epoxy resin, 20g of 2mm quartz sand, 20g of silicon carbide with a particle size of 500μm, 35g of silicon nitride with a particle size of 1μm, 15g of carbon nanotubes with a ...

Embodiment 2

[0038] The preparation of an anti-aging and abrasion-resistant composite material for hydraulic construction comprises the following steps:

[0039] Add 111.14g IPDI to the reaction vessel and pass into nitrogen protection, add 450g PPG1000 dropwise to the reaction vessel, heat up to 80°C for reaction under stirring conditions, continue stirring for 1h, and synthesize isocyanate group-terminated polyurethane prepolymer; The isocyanate-terminated polyurethane prepolymer was cooled down to 30°C under the protection of nitrogen, and 3.70g of glycidol was added dropwise to the reaction vessel. After the dropwise addition, the stirring was continued for 6 hours, and the temperature was raised to 50°C for 3 hours to prepare a polyurethane epoxy resin. Standby; weigh 200g of polyurethane epoxy resin, 100g of unmodified epoxy resin, 60g of 1mm quartz sand, 40g of silicon carbide with a particle size of 300μm, 40g of silicon nitride with a particle size of 200μm, 40g of boron nitride wi...

Embodiment 3

[0041] The preparation of an anti-aging and abrasion-resistant composite material for hydraulic construction comprises the following steps:

[0042] Add 222.29g IPDI to the reaction vessel and pass it under nitrogen protection, add 1600gPTMG2000 dropwise to the reaction vessel, raise the temperature to 60°C under stirring conditions, and continue stirring for 4h to synthesize the isocyanate group-terminated polyurethane prepolymer; The isocyanate-based polyurethane prepolymer was cooled to 40°C under the protection of nitrogen, and 29.63g of glycidol was added dropwise to the reaction vessel, stirred for 1 hour after the dropwise addition, and then heated to 60°C for 4 hours to prepare a polyurethane epoxy resin for use; Take 500g of polyurethane-type epoxy resin, 100g of epoxy resin, 100g of silicon carbide with a particle size of 500 μm, 40g of silicon nitride with a particle size of 500 μm, 40g of boron nitride with a particle size of 500 μm, 105g of aluminum oxide with a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com