Solvent-free synthesis method for ultra-low temperature resistant polyurethane pressure-sensitive adhesive

A synthesis method and pressure-sensitive adhesive technology, applied in the field of solvent-free synthesis, can solve the problems of environmental protection, unfavorable health of operators, and no reported performance, etc., and achieve the effect of good bonding strength and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention will be described in detail below.

[0030] (1) Dehydration of polyether polyols:

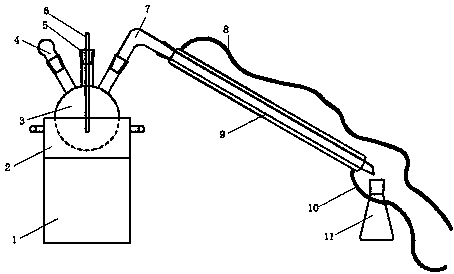

[0031] For example figure 1 As shown, add N-220 in the three-necked flask 3, put the rubber stopper 5 inserted with the thermometer 6 into the middle port of the three-necked flask 3, plug the side port with a glass stopper 4, fix the three-necked flask 3, and Place heating type magnetic stirrer 1, oil bath 2 successively under flask 3. Then install the adapter 7 at the other side port of the three-necked flask 3, then connect the condensation pipe 9 equipped with the rubber outlet pipe 8 and the rubber inlet pipe 10 with the adapter 7, and place the Erlenmeyer flask 11 on the condensation pipe after the connection is completed. directly below the exit.

[0032] After all equipments are connected, turn on the heating magnetic stirrer 1, heat while stirring, and heat the oil bath 2 to dehydrate the N-220 or N-330. Here, the dehydration t...

Embodiment 1

[0048] (1) Dehydration of polyether polyols:

[0049] Put polyether polyol N-220 or polyether polyol N-330 into the three-necked flask 3, connect the equipment, heat while stirring, and heat the oil bath 2 to 120±5°C for N-220 or N- 330 for dehydration treatment for 3h.

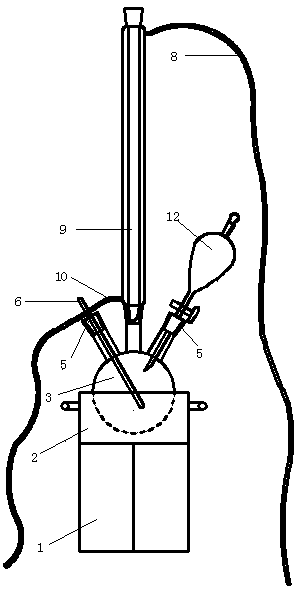

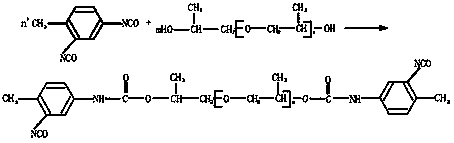

[0050] (2) Synthesis of terminal-NCO-based prepolymers:

[0051] Add dehydrated polyether polyol N-220 into the three-necked flask 3, connect the equipment, heat while stirring, add TDI dropwise into the three-necked flask 3 to react with the polyether polyol N-220, and control the temperature at 40°C. After the dropwise addition of TDI, the temperature was raised using oil bath 2 to keep the reaction temperature at 75°C, and the reaction was refluxed for 3 hours. After the prepolymerization reaction of TDI and N-220 was completed, the material temperature was lowered to room temperature.

[0052] In addition, in the synthesis of the end-NCO group prepolymer, the ratio of the toluene diisocyanate TDI to the...

Embodiment 2

[0057] The polyurethane pressure-sensitive adhesive A2 was obtained in the same manner as in Example 1, except that the temperature during TDI dropwise addition in the synthesis of (2) terminal-NCO group prepolymer in Example 1 was set at 35°C.

[0058] Pressure-sensitive adhesive A2, the bonding strength is 1.0MPa (aluminum-aluminum) at room temperature, and 13MPa (aluminum-aluminum) at -196°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com