High speed railway ballast glue and preparation method and application method thereof

A technology of high-speed railway and ballast glue, which is applied in the field of mechanical materials, can solve the problems of potential safety hazards at stations and along railway lines, affecting the safety of trains, flying ballast and other problems, and achieves convenient construction, good bonding effect, and excellent weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

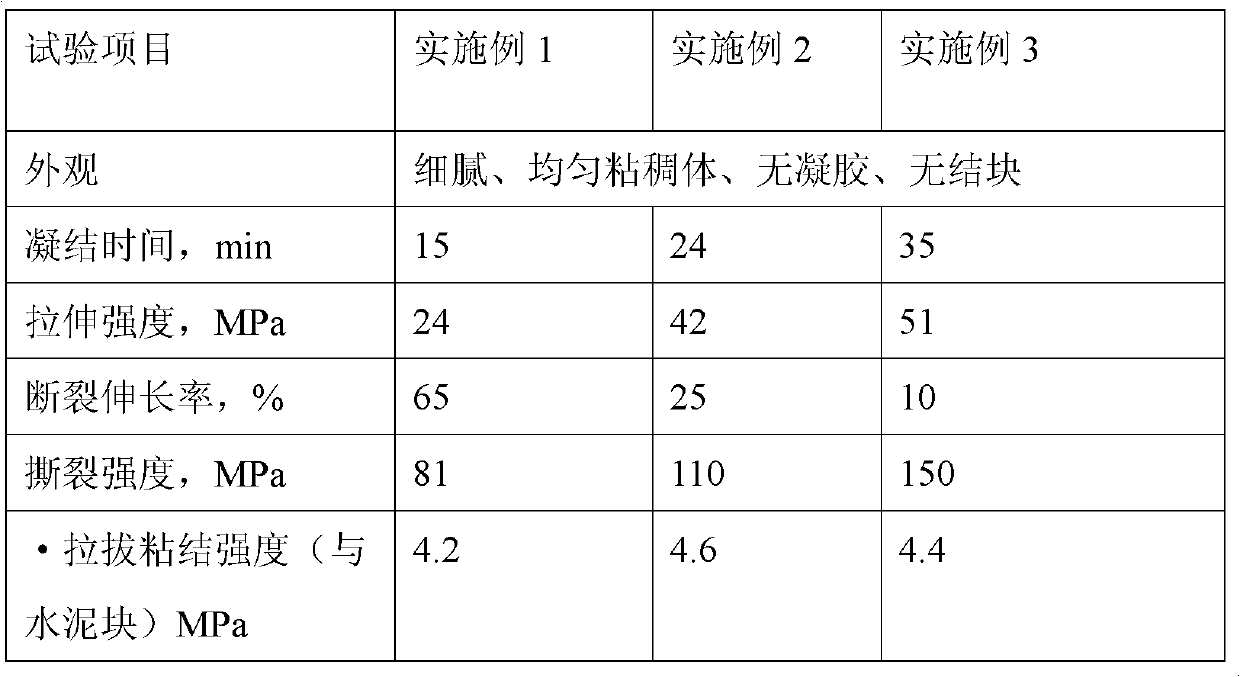

Examples

Embodiment 1

[0029] In the interlayer reactor, first add 60% of Mn=400-2000 low-unsaturation low-molecular-weight polyether polyol, 32% of Mn=400-2000 low-unsaturation high-molecular-weight polyether polyol, at temperature 105-110°C, dehydration under the condition of -0.1MPa vacuum for 2-3 hours, lower the temperature to 60°C, add 3% pigment, 4% small molecule chain extender, 1% auxiliary agent, keep the temperature constant Stir at low speed for 2 hours, then grind three times, cool down to below 50°C, discharge, filter and package to obtain component A.

[0030] In the interlayer reaction kettle, first add 10% of low unsaturation high molecular weight polyether polyol with Mn=400-2000, 30% of plasticizer, at a temperature of 105-110°C and a vacuum of -0.1MPa Dehydrate under conditions for 2-3 hours, cool down to 60°C, add 75% isocyanate, raise the temperature to 70-80°C, keep the temperature constant, react for 1-2 hours, cool down to below 50°C, discharge, filter, and fill with nitroge...

Embodiment 2

[0032] In the interlayer reactor, first add 40% of low-unsaturation low-molecular-weight polyether polyols with Mn=400-2000, 20% of low-unsaturation low-molecular-weight polyether polyols with Mn=400-2000, 32% Mn = 400 ~ 2000 low unsaturation high molecular weight polyether polyol, at a temperature of 105 ~ 110 ° C, vacuum -0.1MPa under the condition of dehydration for 2 ~ 3 hours, cooling to 60 ° C, adding 3% Pigment, 2% small molecule chain extender, 1% additive, keep the temperature constant, stir at low speed for 2 hours, then grind three times, cool down to below 50°C, discharge, filter and package to obtain component A.

[0033] In the interlayer reactor, first add 15% of Mn=400~2000 low unsaturation high molecular weight polyether polyol, 10% of Mn=400~2000 low unsaturation high molecular weight polyether polyol, at temperature Dehydration at 105-110°C and vacuum degree of -0.1MPa for 2-3 hours, lower the temperature to 60°C, add 75% isocyanate, raise the temperature to...

Embodiment 3

[0035] In the interlayer reactor, first add 40% of low-unsaturation low-molecular-weight polyether polyols with Mn=400-2000, 20% of low-unsaturation low-molecular-weight polyether polyols with Mn=400-2000, 32% Mn = 400 ~ 2000 low unsaturation high molecular weight polyether polyol, at a temperature of 105 ~ 110 ° C, vacuum -0.1MPa under the condition of dehydration for 2 ~ 3 hours, cooling to 60 ° C, adding 3% Pigment, 2% small molecule chain extender, 1% auxiliary, keep the temperature constant, stir at low speed for 2 hours, then grind three times, cool down to below 50°C, discharge, filter and pack to obtain component A.

[0036] In the interlayer reactor, first add 15% of low unsaturation high molecular weight polyether polyol with Mn=400-2000, 10% of plasticizer, at a temperature of 105-110°C and a vacuum of -0.1MPa Dehydrate under conditions for 2-3 hours, cool down to 60°C, add 75% isocyanate, raise the temperature to 70-80°C, keep the temperature constant, react for 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com