Anti-bending waterborne transfer coating and preparation method thereof

A transfer coating, anti-bending technology, applied in the field of coatings, can solve the problems of pollution, ink breakage, and the transfer coating is not resistant to bending, so as to improve the bending resistance, improve the bending performance, and overcome the bending resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

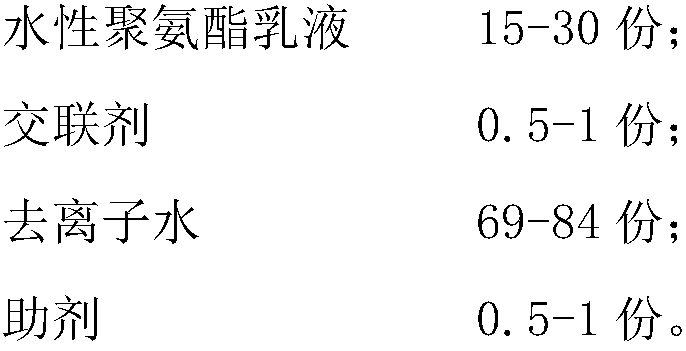

[0029] This embodiment relates to a kind of anti-bending water-based transfer coating, comprising each component of following weight percentage content:

[0030]

[0031] The preparation method of the present embodiment water-based transfer coating comprises:

[0032] Add water-based polyurethane emulsion to deionized water, add Foamex830 and Wet240, stir at 800rpm for 30 minutes, then add carbodiimide, stir at 500rpm for 5 minutes, and filter through a 320-mesh filter to obtain the desired emulsion paint.

[0033] The water-based transfer coating prepared by the above formula is coated with aluminum and transferred to cardboard by roller coating process. The folding resistance can be up to 10 times according to the front and back folding test at 180°C without coating breakage.

Embodiment 2

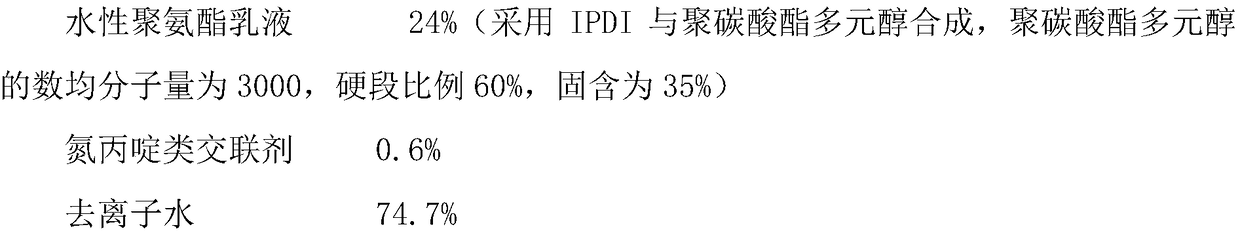

[0035] This embodiment relates to a kind of anti-bending water-based transfer coating, comprising each component of following weight percentage content:

[0036]

[0037]

[0038] The preparation method of the water-based transfer coating of this embodiment is consistent with that of Embodiment 1.

[0039] The water-based transfer coating prepared by the above formula is coated with aluminum and transferred to the cardboard by the roller coating process. The folding resistance can be up to 20 times according to the front and back folding test at 180°C without coating breakage.

Embodiment 3

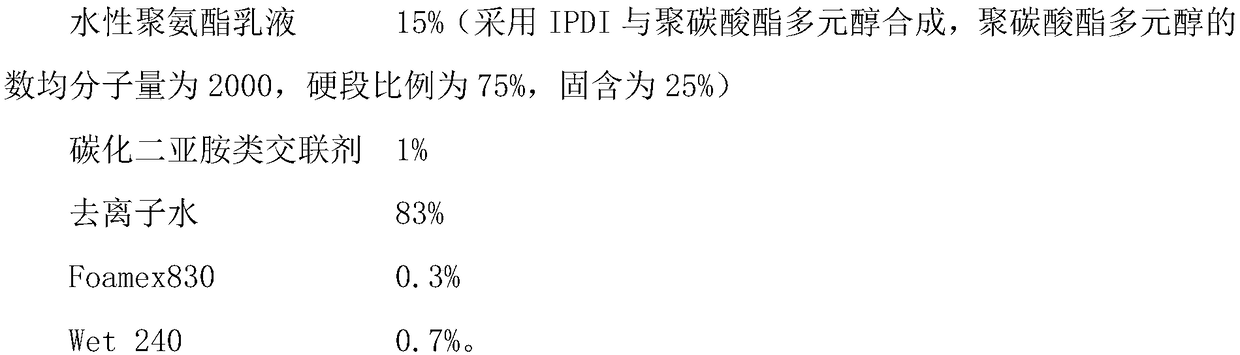

[0041] This embodiment relates to a kind of anti-bending water-based transfer coating, comprising each component of following weight percentage content:

[0042]

[0043] The preparation method of the water-based transfer coating of this embodiment is consistent with that of Embodiment 1.

[0044] The water-based transfer coating prepared through the above formula, the water-based transfer coating prepared through the above formula, is coated with aluminum plating and transferred to the cardboard by the roller coating process, and the folding resistance can reach 40 times according to the front and back 180°C test. Coating cracking phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com