Polyurethane-acrylate oligomer, and synthesis method and application thereof

A technology of polyurethane acrylate and synthesis method, which is applied in the direction of equipment, photoplate making process of patterned surface, optics, etc., can solve the problem of high film hardness, achieve improved adhesion, excellent storage stability and adhesion, and branching The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

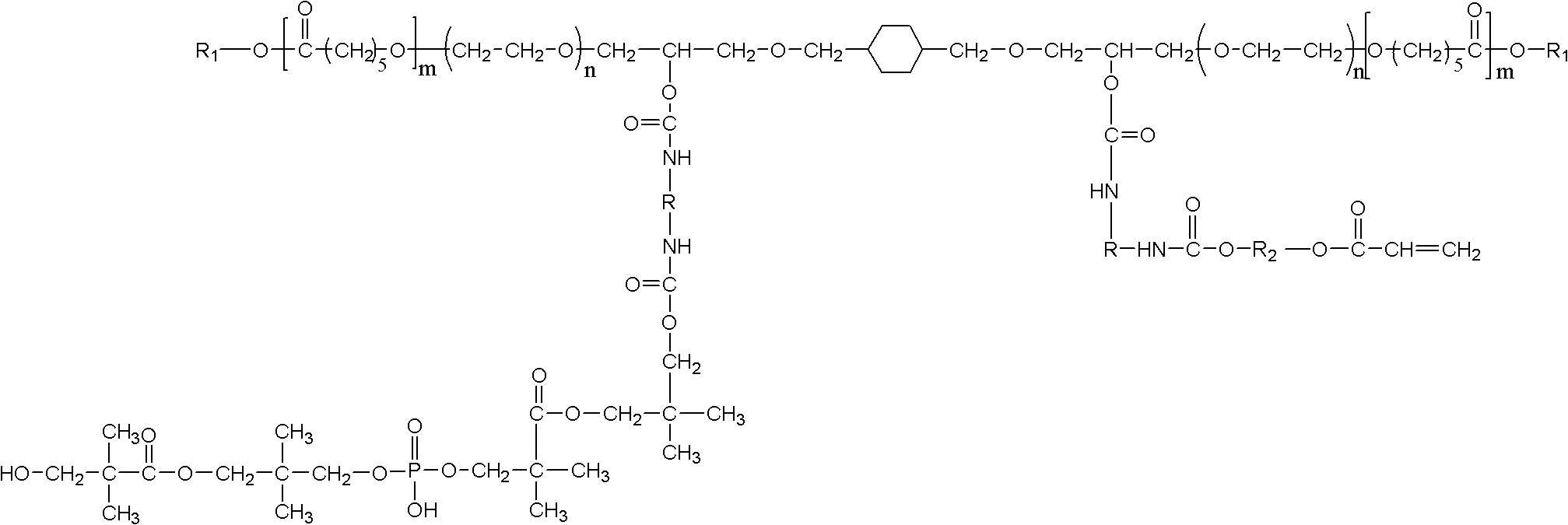

[0081] Example 1 - Urethane Acrylate Oligomer A

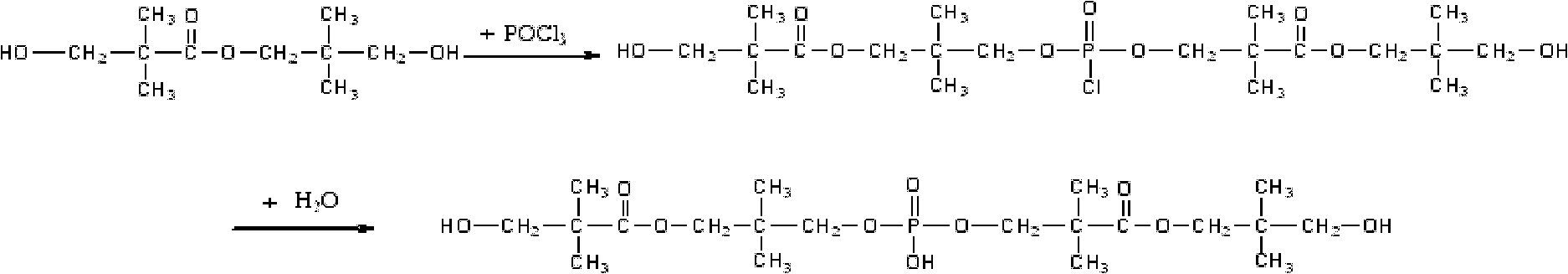

[0082] (1) Synthesis of Phosphate Ester

[0083] Dissolve hydroxypivalic acid neopentyl glycol monoester in toluene, add phosphorus oxychloride dropwise at 40°C for 5 hours, add water for hydrolysis, and react to obtain phosphoric acid ester, hydroxypivalic acid neopentyl glycol monoester and trichloride The mol ratio of oxyphosphorus is 2: 1, and the mol ratio of water and phosphorus oxychloride is 1: 1;

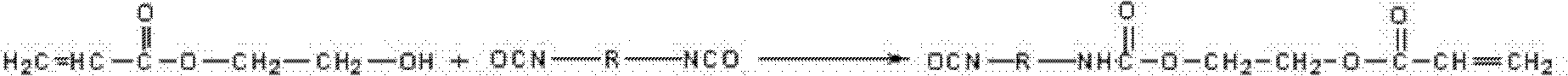

[0084] (2) Synthesis of semi-adducts

[0085] Under the protection of nitrogen, hydroxyethyl acrylate (HEA) and the phosphoric acid ester in step (1) and dibutyltin dilaurate (DBTDL) were added dropwise to hexamethylene diisocyanate respectively, and the reaction temperature was kept at 50°C, and monitored The concentration of the -NCO group in the system changes until the concentration of the -NCO group no longer changes (the concentration of the -NCO group is detected by the di-n-butylamine method), and the hydroxyl este...

Embodiment 2

[0093] Example 2 - Urethane Acrylate Oligomer B

[0094] (1) Synthesis of Phosphate Ester

[0095] Dissolve hydroxypivalic acid neopentyl glycol monoester in toluene, add phosphorus oxychloride dropwise at 50°C for 4 hours, add water for hydrolysis, and react to obtain phosphoric acid ester, hydroxypivalic acid neopentyl glycol monoester and trichloride The mol ratio of oxyphosphorus is 2: 1.05, and the mol ratio of water and phosphorus oxychloride is 1.05: 1;

[0096] (2) Synthesis of semi-adducts

[0097] Under the protection of nitrogen, hydroxypropyl acrylate (HPA) and the phosphoric acid ester in step (1) and dibutyltin dilaurate (DBTDL) were added dropwise to isophorone diisocyanate respectively, and the reaction temperature was kept at 40° C., monitored The concentration of the -NCO group in the system changes until the concentration of the -NCO group no longer changes (the concentration of the -NCO group is detected by the di-n-butylamine method), and the hydroxyl es...

Embodiment 3

[0105] Example 3 - Urethane Acrylate Oligomer C

[0106] (1) Synthesis of Phosphate Ester

[0107] Dissolve hydroxypivalic acid neopentyl glycol monoester in toluene, add phosphorus oxychloride dropwise at 60°C for 3 hours, add water for hydrolysis, and react to obtain phosphoric acid ester, hydroxypivalic acid neopentyl glycol monoester and trichloride The mol ratio of oxyphosphorus is 2: 1, and the mol ratio of water and phosphorus oxychloride is 1.05: 1;

[0108] (2) Synthesis of semi-adducts

[0109] Under the protection of nitrogen, add hydroxyethyl acrylate, phosphate ester and dibutyltin dilaurate (DBTDL) in step (1) to toluene diisocyanate dropwise, keep the reaction temperature at 50°C, and monitor the -NCO group in the system The concentration of the concentration changes until the concentration of the -NCO group no longer changes (the concentration of the -NCO group is detected by the di-n-butylamine method), and the semi-adducts of the hydroxyl ester type toluene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com