Bismuth ferrate-barium titanate-bismuth zinc titanate-bismuth aluminate high-temperature lead-free piezoelectric ceramic and preparation method thereof

A bismuth zinc titanate and lead-free piezoelectric technology, which is applied in the field of bismuth ferrite-barium titanate-bismuth zinc titanate-bismuth aluminate high-temperature lead-free piezoelectric ceramics and its preparation, can solve the problems of miscellaneous items, synthesis Difficulties and other problems, to achieve the effect of high Curie temperature and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Composition: 0.70BiFeO 3 -0.20BaTiO 3 -0.05Bi(Ti 0.5 Zn 0.5 )O 3 -0.05BiAlO 3 +0.01Li 2 CO 3 +0.01MnCO 3 +0.025Bi 2 o 3 , the preparation method comprises the following steps:

[0022] (1) To analyze pure TiO 2 、BaCO 3 As raw material, according to BaTiO 3 The mixed powder is ball milled with absolute ethanol as the medium for 24 hours, dried in an oven at 100°C / 12 hours, passed through a 200-mesh sieve, put into a high-alumina crucible for compaction and capped, and then put into a muffle Synthesize in a furnace at 980°C for 6 hours, cool down to below 200°C and take it out for use;

[0023] (2) BaTiO synthesized in step (1) 3 with analytically pure Bi 2 o 3 、TiO 2 , ZnO, Li 2 CO 3 As raw material, according to 1.0BaTiO 3 -0.5Bi(Ti 0.5 Zn 0.5 )O 3 +0.05Li 2 CO 3 The proportion of ingredients is mixed, the mixed powder is ball milled with absolute ethanol as the medium for 24 hours, taken out and dried in an oven at 100°C / 12 hours, passed throug...

Embodiment 2

[0035] Composition 0.725BiFeO 3 -0.175BaTiO 3 -0.075Bi(Ti 0.5 Zn 0.5 )O 3 -0.025BiAlO 3 +0.01Li 2 CO 3 +0.01MnCO 3 +0.025Bi 2 o 3 , the preparation method is the same as in Example 1, except that the formula ratio is changed, and the sintering temperature in step (7) is 960° C. for 120 minutes.

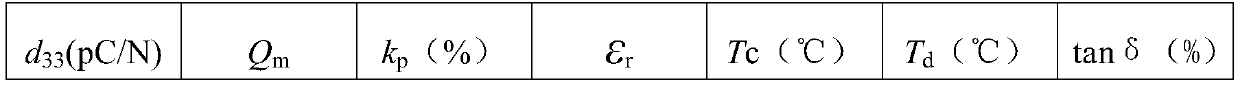

[0036] The performance measurements are as follows:

[0037] d 33 (pC / N)

Embodiment 3

[0039] Composition: 0.75BiFeO 3 -0.175BaTiO 3 -0.05Bi(Ti 0.5 Zn 0.5 )O 3 -0.025BiAlO 3 +0.006CuO+0.01MnCO 3 +0.025Bi 2 o 3 , the preparation method is the same as in Example 1, except that the formula is changed, CuO is used, and the sintering temperature in step (7) is 960° C. for 120 minutes.

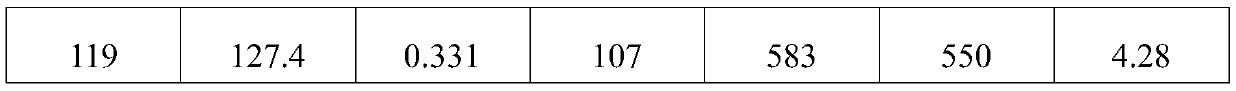

[0040] The performance measurements are as follows:

[0041] d 33 (pC / N)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com