Flux-free aluminum brazing sheet

A technology of aluminum brazing and brazing material, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] For various brazing sheets with the compositions shown in Tables 1 to 6 (core material, brazing filler metal, sacrificial material; the remainder being Al and unavoidable impurities), under the casting conditions and hot rolling conditions shown in Table 7 , produced a hot-rolled plate.

[0146] In addition, no sacrificial material was used for the test material whose composition of the sacrificial material is indicated by "-".

[0147]Then, by cold rolling including an intermediate annealing step, a cold-rolled sheet having a thickness of 0.30 mm in the H14 equivalent temper was produced. In addition, the coating ratio of each layer was 10% of brazing material and 15% of sacrificial material.

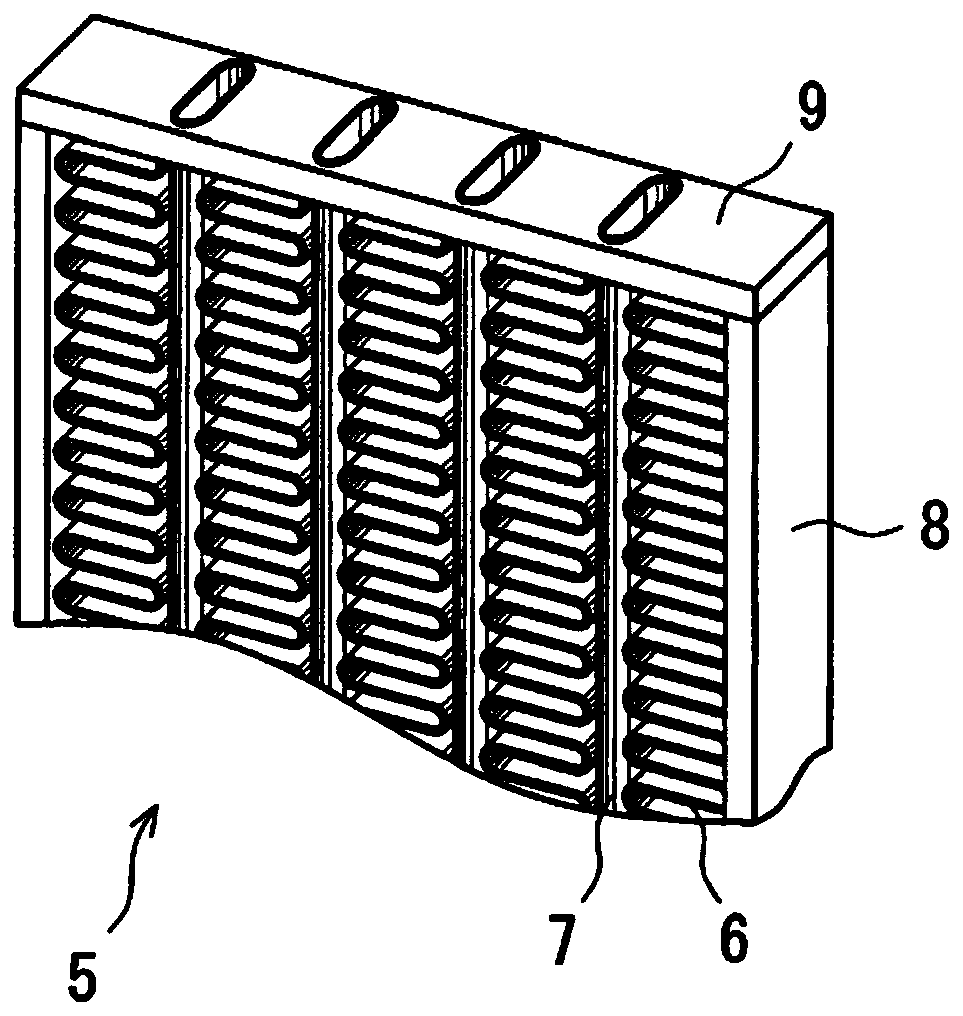

[0148] Furthermore, corrugated fins of A3003 alloy and H14 aluminum bare material (thickness 0.06 mm) were prepared as brazing target members.

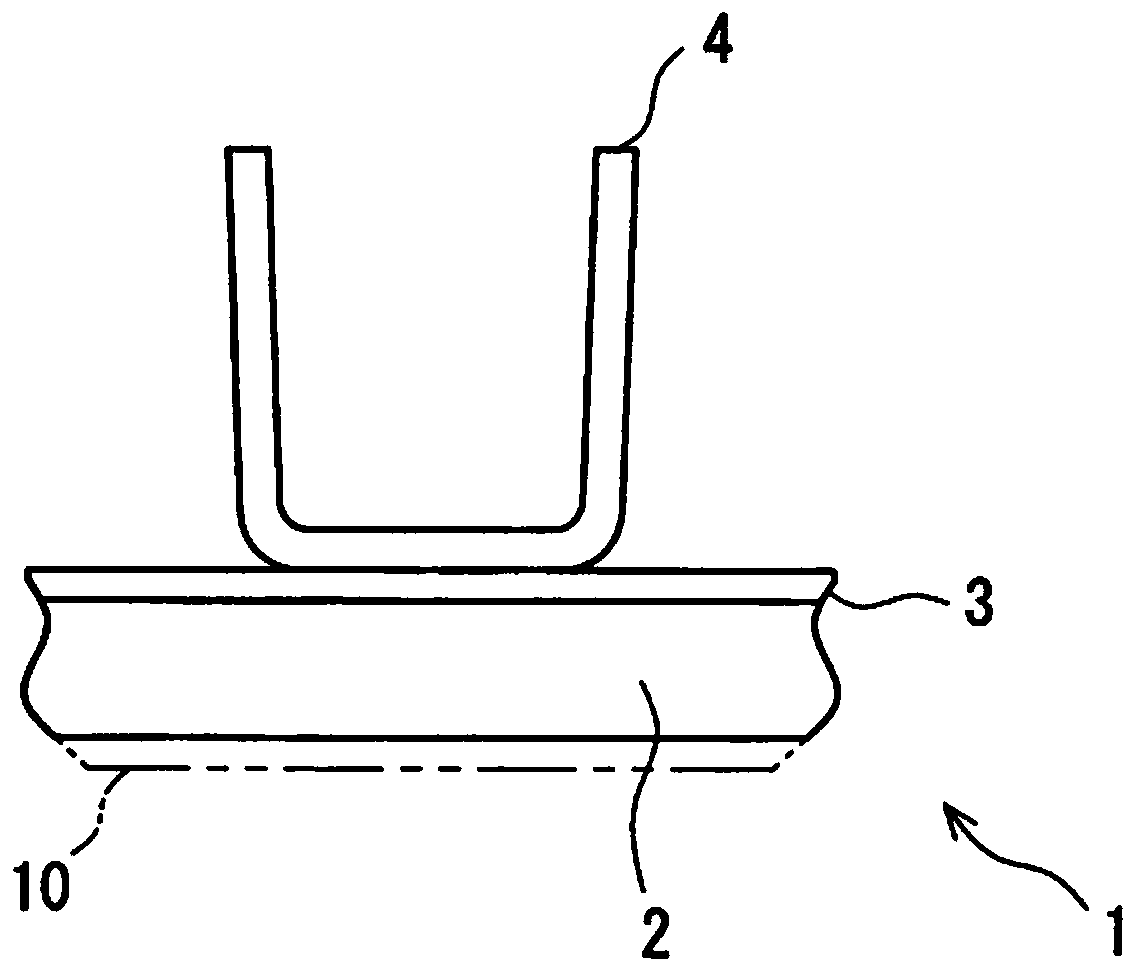

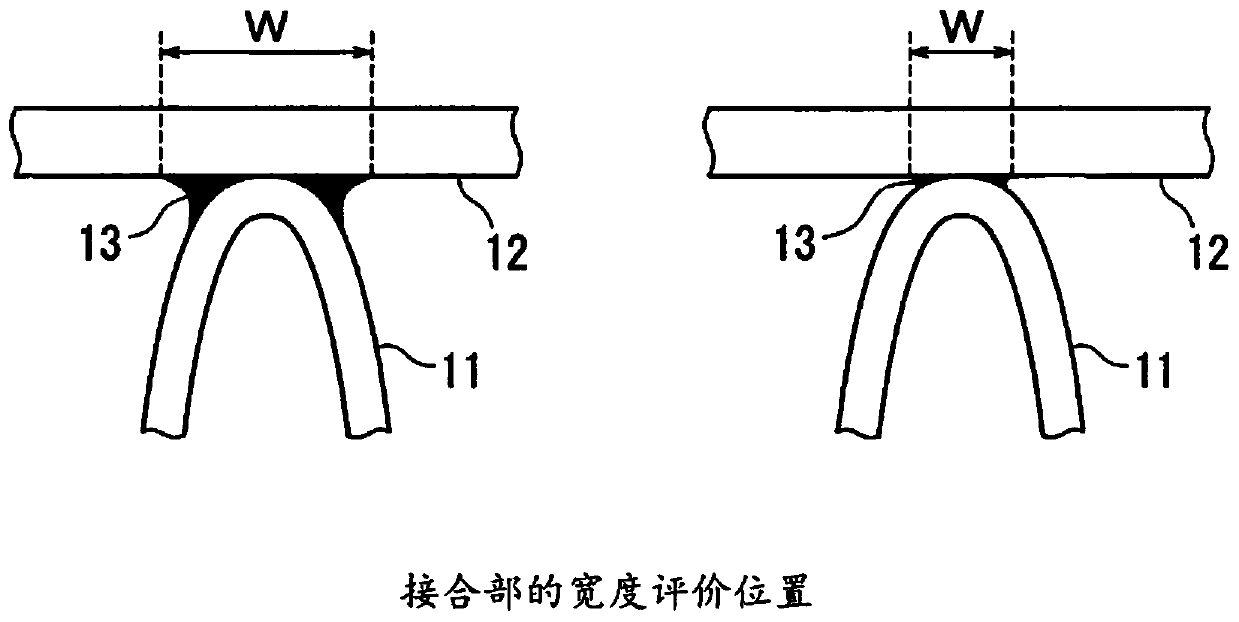

[0149] Use the aluminum brazing plate to make a tube with a width of 25 mm, and combine the tube and corrugated fins so that the tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com