Al-Zn-Mg-Si alloy for hot dipping steel

A hot-dip plating and alloying technology, which is applied in the hot-dip plating process, metal material coating process, coating, etc., can solve the problem of deteriorating coating surface performance and processing performance, reducing the viscosity of the plating solution, and refining the corrosion resistance of the grain Issues such as insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

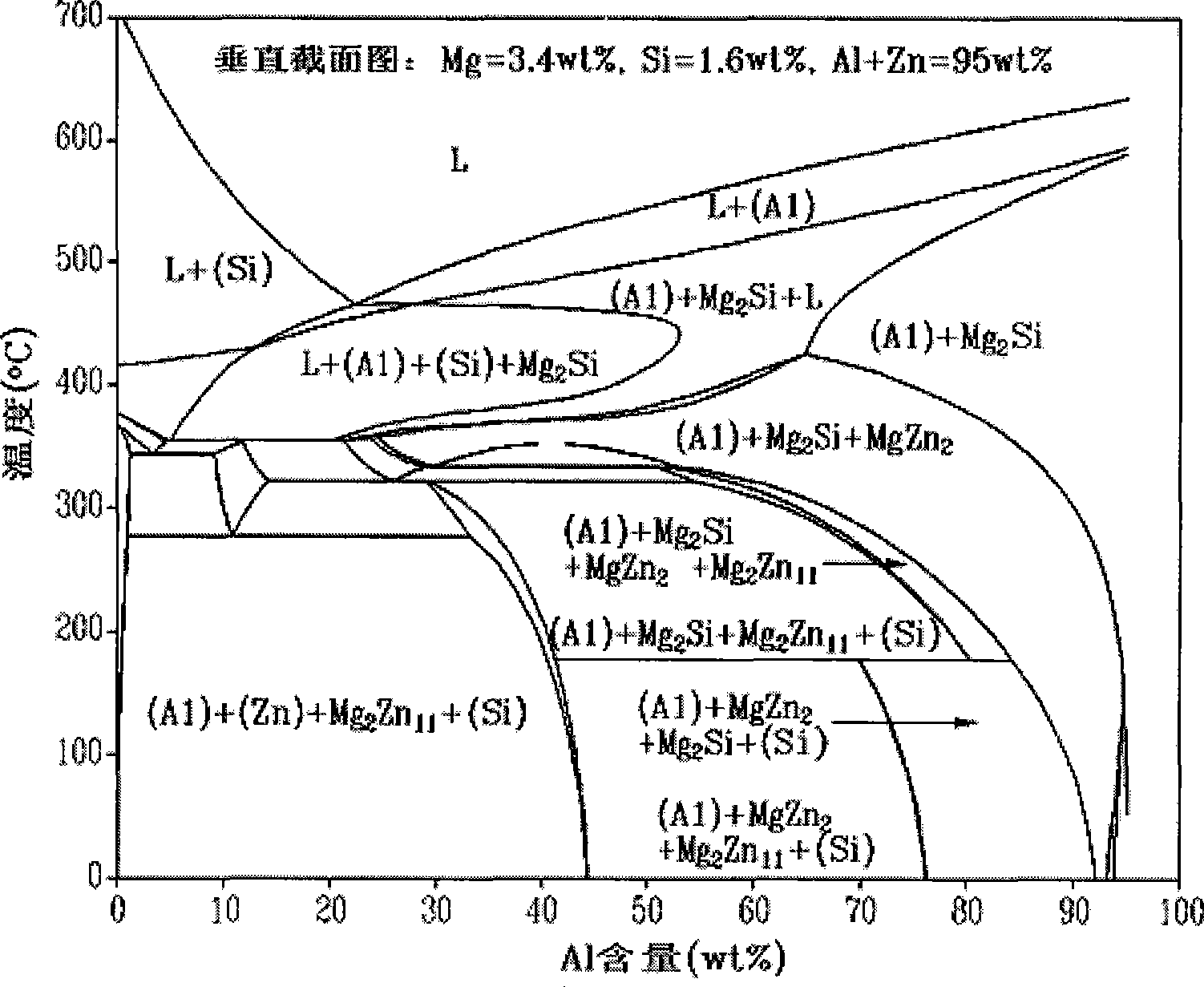

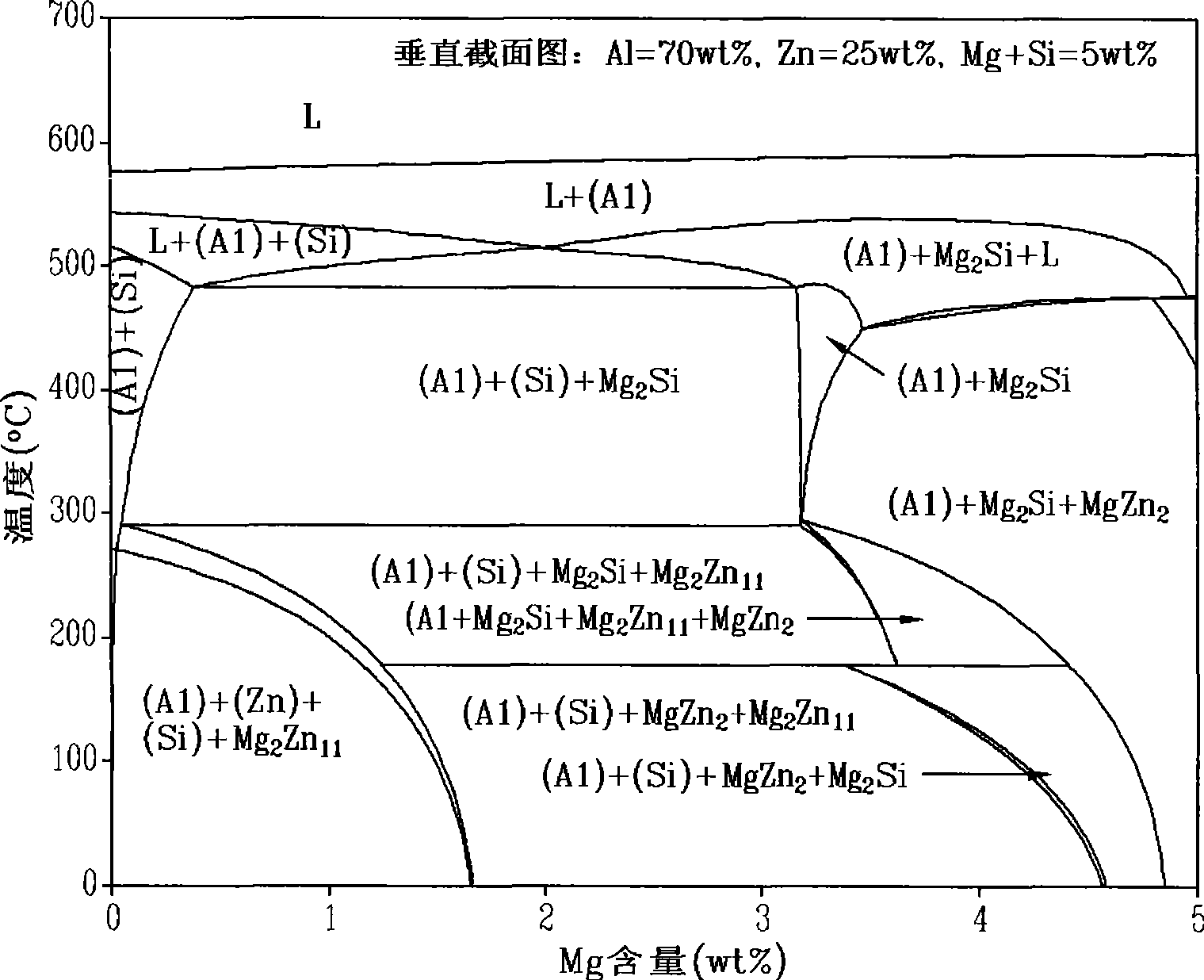

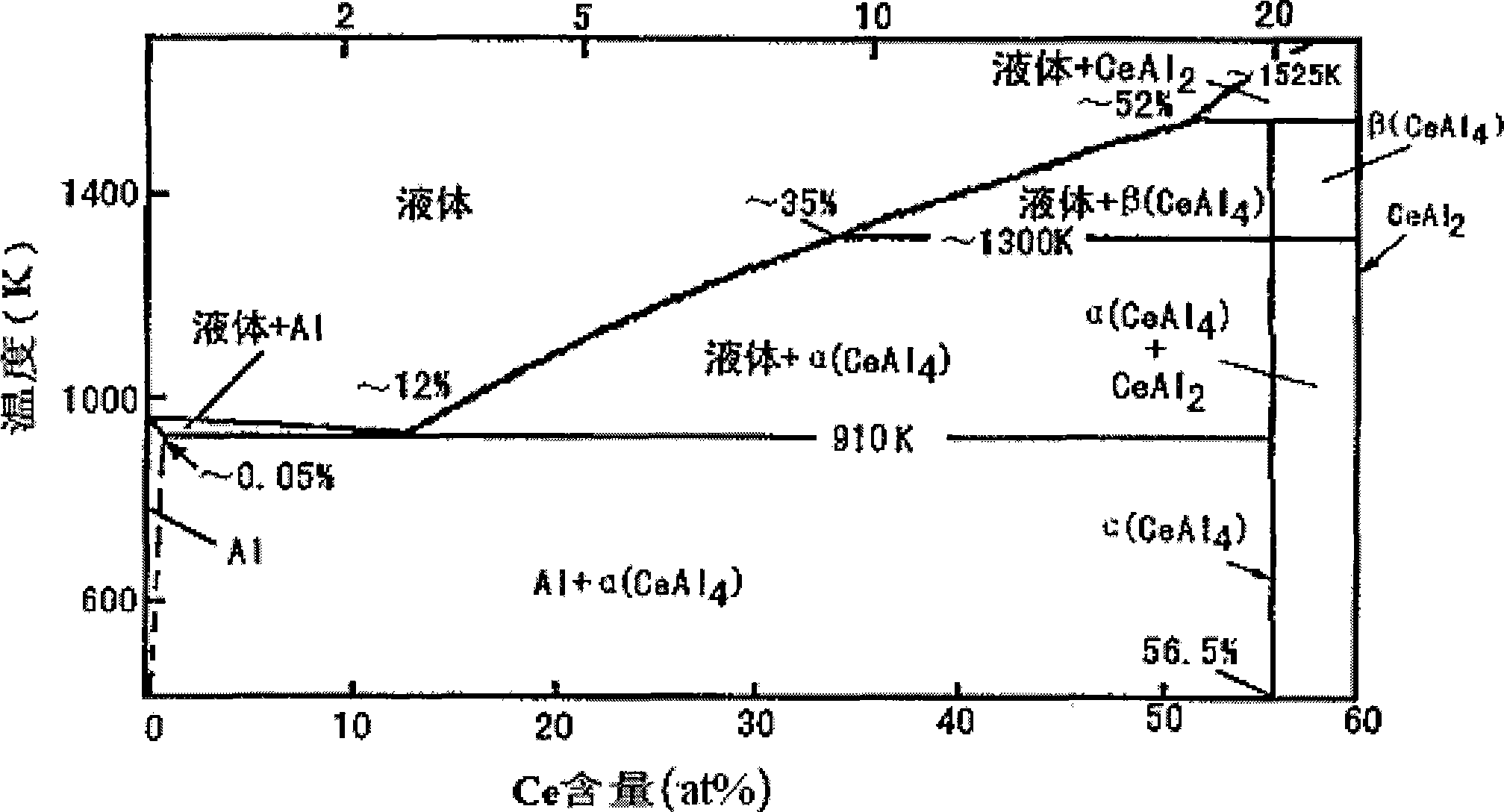

[0026] Embodiments of the present invention are described as follows in conjunction with accompanying drawings:

[0027] Using a continuous hot-dip galvanizing simulation device (continuous hot-dip galvanizing test line), the surface of the prepared steel plate is attached with Al-Zn-Mg-Si alloy coatings with different composition contents. Plating conditions are as follows:

[0028] Steel plate treatment: take a Q235 steel plate with a size of 100mm×100mm×1mm as a plated piece, degrease and deoxidize it, and then wash it clean.

[0029] Plating solution alloy: within the scope of this patent, the configured alloys for hot-dip plating are shown in Table 1.

[0030] Bath temperature: 580-650°C

[0031] Hot plating time: 10-30 seconds

[0032] Average cooling rate: 25°C / s

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com