Composite coating layer for eliminating heavy metal chromium and VOCs pollution from source, and preparation method thereof

A composite coating, source technology, applied in the direction of metal material coating process, coating, powder coating, etc., can solve the problem that the performance of aluminum and aluminum alloy materials cannot meet the application requirements, the thickness of fluorocarbon powder is high, and the leveling performance Bad etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

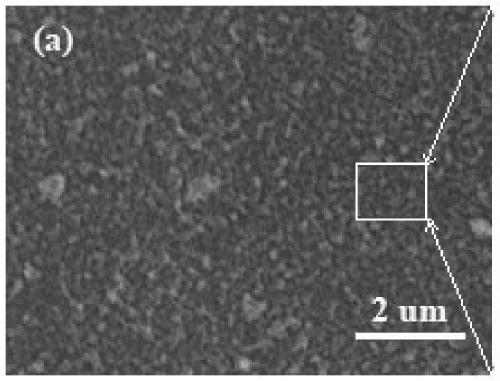

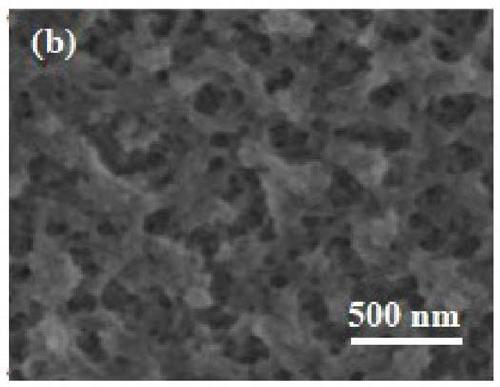

Image

Examples

Embodiment 1

[0093] Composite coatings were prepared using the following methods:

[0094] (1) Etching treatment is carried out on the metal surface to be treated, and the etching amount is 1.2g / m 2 ;

[0095] (2) Spray the surface pretreatment liquid evenly on the surface of the metal to be treated, the spray pressure is 0.03MPa, and the treatment time is 20s to form a conversion film layer. The surface pretreatment liquid includes the following components by weight percentage: 2, 4,6-trihydroxybenzoic acid 0.3mmol / L, sodium fluorozirconate 0.5mmol / L, dilute sulfuric acid solution of manganese fluoride dihydrate 0.1mmol / L, potassium fluoride 0.1mmol / L, maleic acid di Sodium isooctyl sulfonate 6×10 -6 mmol / L, adjust the pH to 4.2;

[0096] (3) Carry out drying treatment on the conversion coating layer, the temperature is controlled at 80° C., and dried for 20 minutes;

[0097] (4) With the conversion film layer as the transition layer, use the method of electrostatic spraying to spray ...

Embodiment 2

[0100] Composite coatings were prepared using the following methods:

[0101] (1) Etching treatment is carried out on the metal surface to be treated, and the etching amount is 1.5g / m 2 ;

[0102] (2) Soak the metal to be treated in the surface pretreatment solution for 12 minutes to form a conversion film layer. The surface pretreatment solution includes the following components by weight percentage: 1.0mmol / L of 3,4,5-trihydroxybenzoic acid, fluorine Titanic acid 0.3mmol / L, dilute sulfuric acid solution of manganese fluoride dihydrate 0.5mmol / L, potassium sulfate 0.2mmol / L, diisooctyl ammonium maleate 2×10 -6 mmol / L, adjust the pH to 2.6;

[0103] (3) Carry out drying treatment on the conversion coating layer, the temperature is controlled at 100° C., and dried for 10 minutes;

[0104] (4) With the conversion film layer as the transition layer, spray fluorocarbon powder coating with 80% FEVE resin content on its surface by electrostatic spraying method to form the coating...

Embodiment 3

[0107] Composite coatings were prepared using the following methods:

[0108] (1) Etching treatment is carried out on the metal surface to be treated, and the etching amount is 1.3g / m 2 ;

[0109] (2) The surface pretreatment liquid is evenly coated on the surface of the metal to be treated, and the treatment time is 20s to form a conversion film layer. The surface pretreatment liquid includes the following components by weight percentage: 3,4,5-trihydroxybenzene Formaldehyde 0.2mmol / L, ammonium fluorozirconate 0.1mmol / L, dilute sulfuric acid solution of manganese fluoride dihydrate 0.3mmol / L, potassium hexafluorochlorate 0.5mmol / L, diisooctyl maleate sodium sulfonate 4 ×10 -6 mmol / L, adjust the pH to 3.0;

[0110] (3) Carry out drying treatment on the conversion coating layer, the temperature is controlled at 120° C., and dried for 15 minutes;

[0111] (4) With the conversion film layer as the transition layer, use the method of electrostatic spraying to spray fluorocarbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com