Bismuth-containing biphase mixed conductor oxygen permeation membrane material with carbon dioxide resistance and high stability and preparation method thereof

A high-stability, mixed-conductor technology, used in chemical instruments and methods, separation methods, semi-permeable membrane separation, etc., can solve problems such as poor stability, and achieve the effect of dense surface, excellent mechanical properties, and good oxygen permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

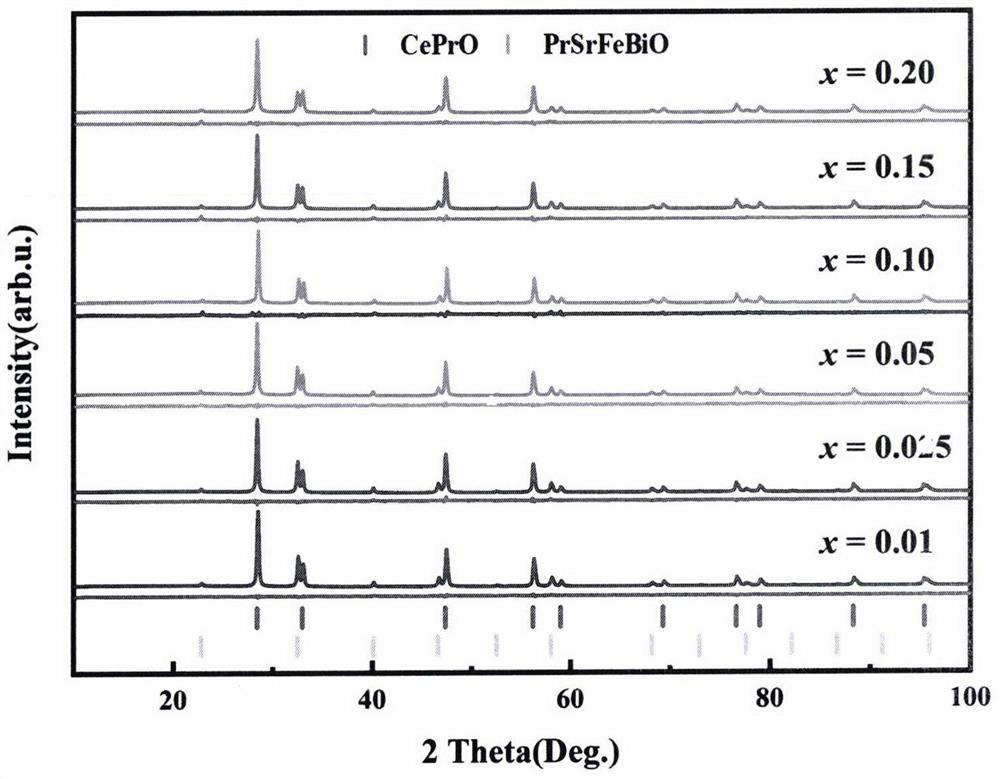

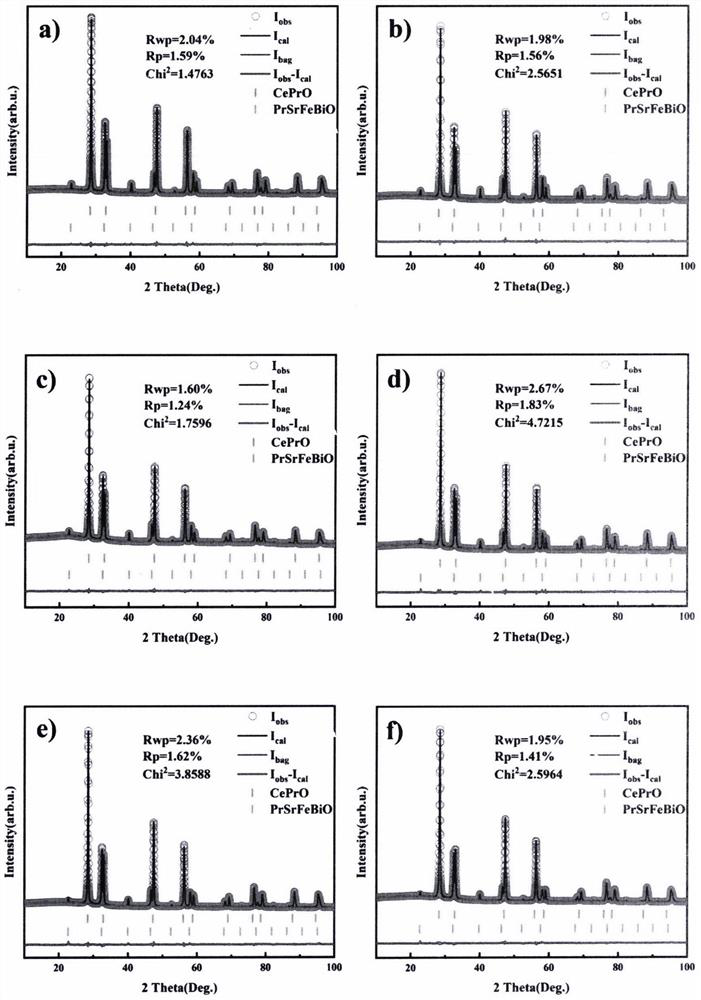

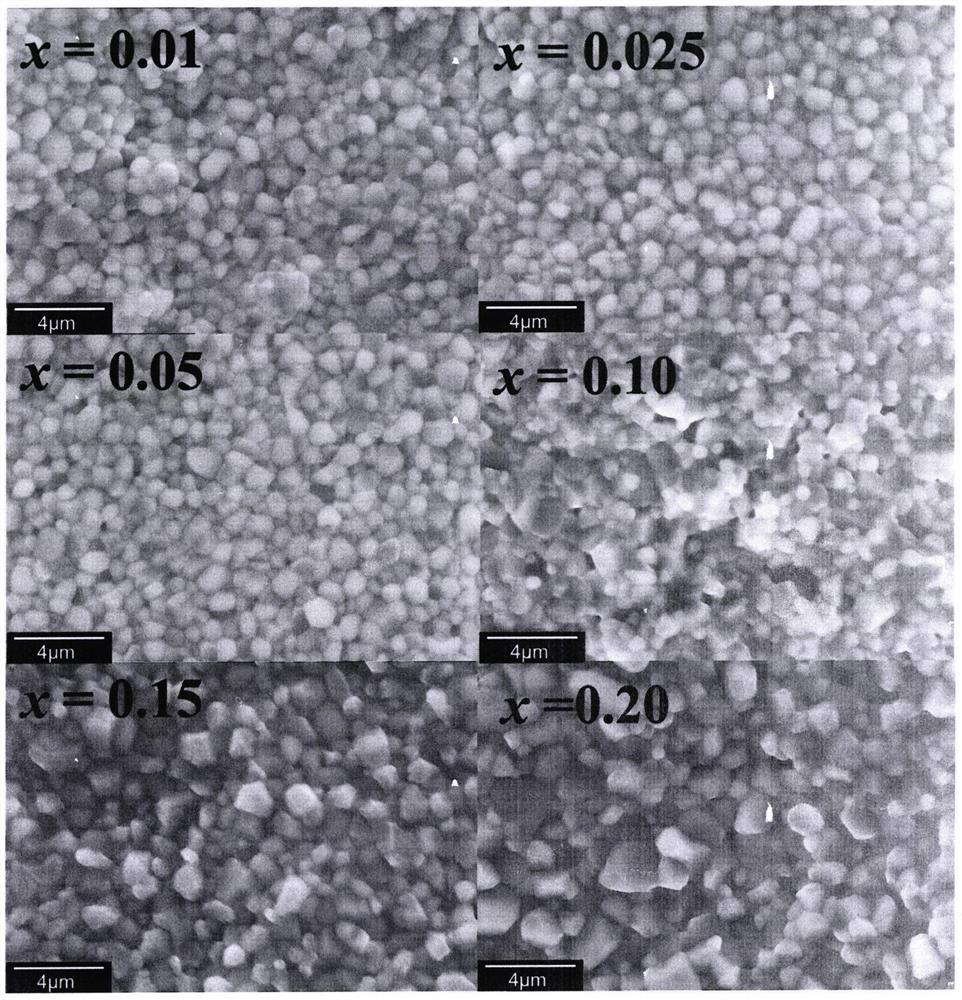

Embodiment 1

[0032] Accurately weigh 4.1057g Ce(NO 3 ) 3 ·6H 2 O, 1.8656g Pr(NO 3 ) 3 ·6H 2 O, 2.1336g Fe(NO 3 ) 3 9H 2 O. 0.4538g Sr(NO 3 ) 2 , 0.0261g Bi(NO 3 ) 3 ·5H 2 O, 8.7669g citric acid monohydrate, stir the solution until it becomes clear and transparent, place the beaker on a magnetic stirrer, continue heating and evaporating until it turns into a gel, and then put the gel in an oven at 140 ° C for 24 hours to obtain The dry gel is fluffy, and after being fully ground, it is put into a crucible and kept at 600°C for 8 hours for calcination to remove organic matter. The calcined powder is fully ground and placed in a crucible, and calcined at 950°C for 10 hours to obtain Ce 0.9 PR 0.1 o 2-δ -Pr 0.6 Sr 0.4 Fe 0.99 Bi 0.01 o 3-δ The powder is pressed at 10MPa to obtain a cake-shaped sheet, and the sheet is slowly heated up at 1400°C for 5 hours and sintered to obtain a dense dual-phase ceramic oxygen-permeable membrane material, and sanded to obtain a high-stabil...

Embodiment 2

[0034] Accurately weigh 4.1057g Ce(NO 3 ) 3 ·6H 2 O, 1.8514g Pr(NO 3 ) 3 ·6H 2 O, 2.0800g Fe(NO 3 ) 3 9H 2 O, 0.4492g Sr(NO 3 ) 2 , 0.0647g Bi(NO 3 ) 3 ·5H 2 O, 8.7669g citric acid monohydrate, stir the solution until it becomes clear and transparent, place the beaker on a magnetic stirrer, continue heating and evaporating until it turns into a gel, and then put the gel in an oven at 140 ° C for 24 hours to obtain The dry gel is fluffy, and after being fully ground, it is put into a crucible and kept at 600°C for 8 hours for calcination to remove organic matter. The calcined powder is fully ground and placed in a crucible, and calcined at 950°C for 10 hours to obtain Ce 0.9 PR 0.1 o 2-δ -Pr 0.6 Sr 0.4 Fe 0.975 Bi 0.025 o 3-δ The powder is pressed at 10MPa to obtain a cake-shaped sheet, and the sheet is slowly heated up at 1400°C for 5 hours and sintered to obtain a dense dual-phase ceramic oxygen-permeable membrane material, and sanded to obtain a high-stab...

Embodiment 3

[0036] Accurately weigh 4.1057g Ce(NO 3 ) 3 ·6H 2 O, 1.8283g Pr(NO 3 ) 3 ·6H 2 O, 1.9932g Fe(NO 3 ) 3 9H 2 O, 0.4418g Sr(NO3 ) 2 , 0.1272g Bi(NO 3 ) 3 ·5H 2 O, 8.7669g citric acid monohydrate, stir the solution until it becomes clear and transparent, place the beaker on a magnetic stirrer, continue heating and evaporating until it turns into a gel, and then put the gel in an oven at 140°C for 24 hours to obtain The dry gel is fluffy, and after being fully ground, it is put into a crucible and kept at 600°C for 8 hours for calcination to remove organic matter. The calcined powder is fully ground and placed in a crucible, and calcined at 950°C for 10 hours to obtain Ce 0.9 PR 0.1 o 2-δ -Pr 0.6 Sr 0.4 Fe 0.95 Bi 0.05 o 3-δ The powder is pressed at 10MPa to obtain a cake-shaped sheet, and the sheet is slowly heated at 1400°C for 5 hours to sinter to obtain a dense dual-phase ceramic oxygen-permeable membrane material, and sanded to obtain a high-stability bismut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com