Rice hull fuel forming method

A molding method and rice husk technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems that biomass fuel molding is difficult to popularize, biomass energy pellet products are not common, and the energy consumption of molding equipment is large, so as to achieve convenient Continuous and stable production, flexible and adjustable drying time, and reduced drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

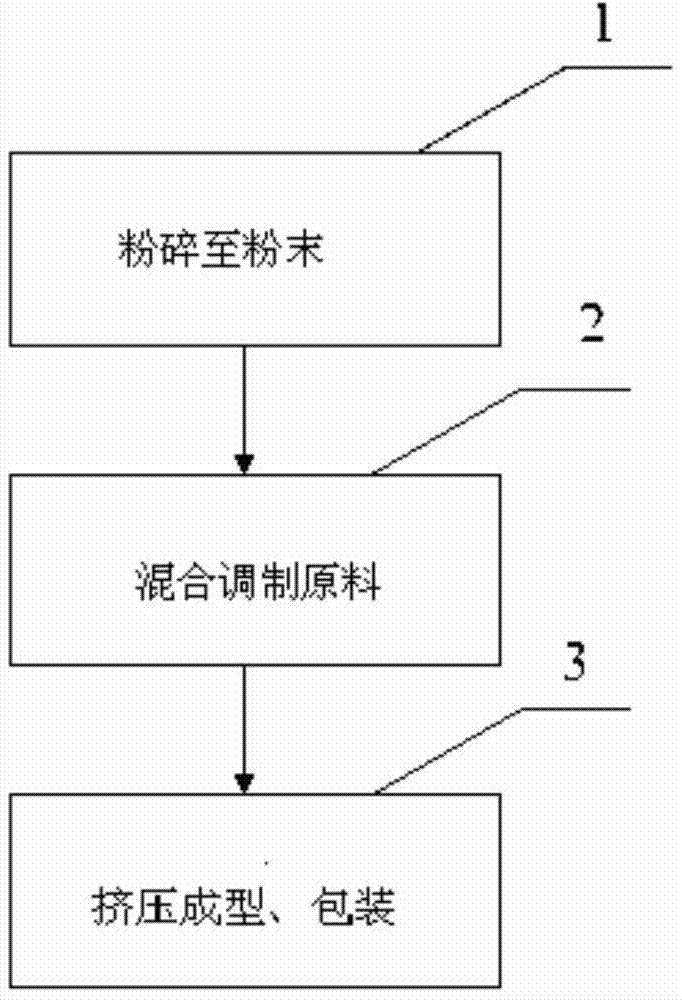

Image

Examples

Embodiment Construction

[0023] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0024] Following examples are further descriptions of the present invention:

[0025] Rice husk collection: mainly rice processing factories and farmers;

[0026] Primary selection of 60 kg of paddy rice husks, after filtering and sieving to remove impurities, crushing the rice husks into powder by passing through a 1.5mm sieve plate crusher; then taking 18 kg of crushed sawdust, 16 kg of pulverized coal and 6 kg of additives ( 3 kg of sulfur-fixing agent and 3 kg of anti-slagging agent); the above materials are poured into the mixer and stirred evenly, and the humidity of the raw materials after stirring is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com