Geopolymer coating layer suitable for metal substrate and preparation method of geopolymer coating layer

A technology of metal substrates and geopolymers, applied in cement production, etc., can solve the problems of low bonding strength of metal substrates, large differences in properties and metals, and large coating thickness, etc., to achieve low raw material costs, uniform thickness, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

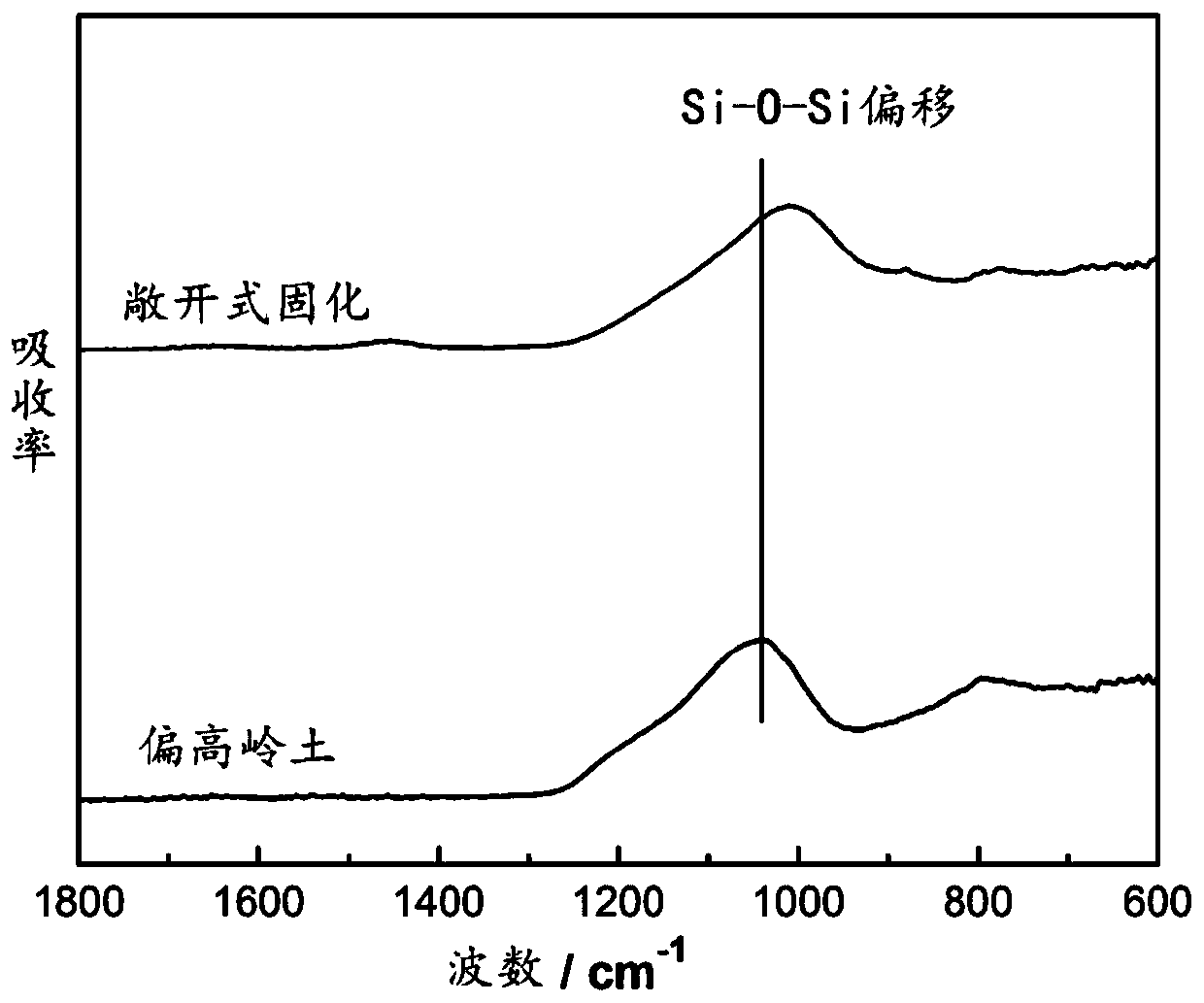

[0033] Prepare metakaolin-based polymer coating on the surface of Al alloy, the specific steps are as follows:

[0034] 1) take by weighing 100g sodium silicate (which contains 80wt% Na 2 O 3.35SiO 2 , 20wt% H 2 O), 6.7g of NaOH and 150g of H 2 O, and then mixed uniformly and placed in a 40°C oven for 24h to obtain a transparent alkali activator; then weighed 99g metakaolin (containing 55wt% of SiO 2 , 39wt% Al 2 o 3 and 6wt% impurity) and 256.7g of the base activator, the two were mixed in a stirrer, the stirrer speed was 700r / min, and the stirring time was 10min. A metakaolin-based geopolymer precursor that is uniformly mixed and fluid is obtained.

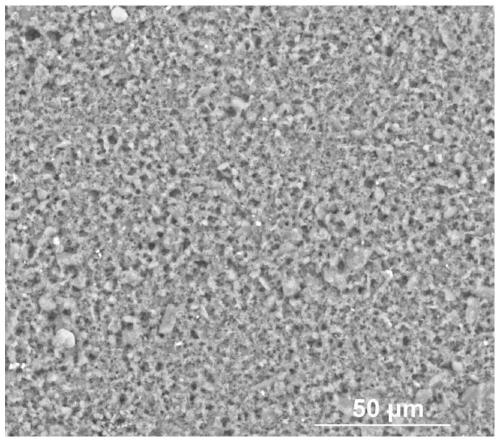

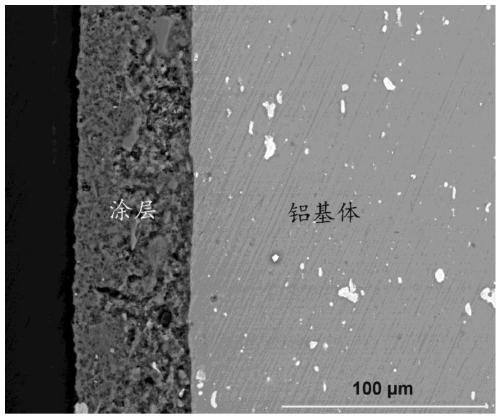

[0035] 2) Pour the metakaolin-based geopolymer precursor prepared in step 1) into a container, and use an air spray gun to spray on the surface of the Al alloy that has undergone degreasing treatment. The air pressure during spraying is 0.6MPa, and the spraying time is 5s; Geopolymer precursor coating.

[0036] 3) Curing...

Embodiment 2

[0041] Prepare the metakaolin-based polymer coating on the steel surface, and the specific steps are as follows:

[0042] 1) take by weighing 100g sodium silicate (which contains 80wt% Na 2 O 3.35SiO 2 , 20wt% H 2 O), 9.2g NaOH and 160H 2 O, and then mixed uniformly and placed in a 40°C oven for 24h to obtain a transparent alkali activator; then weigh 107g metakaolin (containing 55wt% of SiO 2 , 39wt% Al 2 o 3 and 6wt% impurity) and 269.2g of the base activator, the two were mixed in a stirrer, the stirrer speed was 500r / min, and the stirring time was 20min. A metakaolin-based geopolymer precursor that is uniformly mixed and fluid is obtained.

[0043] 2) Pour the metakaolin-based geopolymer precursor prepared in step 1) into a container, and use an air spray gun to spray on the steel surface that has undergone degreasing treatment. The air pressure during spraying is 0.5MPa, and the spraying time is 10s; Geopolymer precursor coating.

[0044] 3) Curing the geopolymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com