Device and process for recycling trimethylamine

A recovery device and trimethylamine technology, applied in the field of trimethylamine recovery device and its recovery process, can solve the problems of people's direct and indirect economic losses, affect the normal life of human beings, and deteriorate the ecological environment of water bodies, so as to reduce the energy consumption of aeration, The effect of small footprint and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

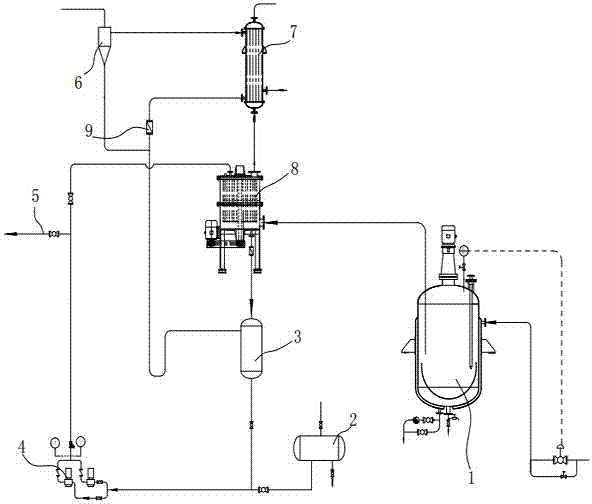

Image

Examples

Embodiment 2

[0030] Embodiment 2: in the continuous distillation process, in 5000L reaction evaporator 1, add trimethylamine waste water continuously, trimethylamine concentration is 5-17% and dosage 1m3 / h, then continuously add 30% liquid caustic soda, The dosage of 30% liquid caustic soda is 1.5L / h, the pH of the adjusted solution is about 9, the temperature at the bottom of the reaction evaporator 1 is 98°C, and the temperature at the top of the reaction evaporator 1 is 89°C. The temperature at the bottom of the distillation tower 8 is 89° C., and the temperature at the top of the rectification tower 8 is 70° C. Trimethylamine escapes evenly. The concentration of trimethylamine recovered is 45%, and the concentration of trimethylamine in the raffinate is 0.4%.

Embodiment 3

[0031] Embodiment 3: in continuous distillation process, in 5000L reaction evaporation kettle 1, add trimethylamine waste water continuously, trimethylamine concentration is 5-17% and dosage 1m3 / h, then continuously add 30% liquid caustic soda, The dosage of 30% liquid caustic soda is 1.5L / h, the pH of the adjusted solution is about 9, the temperature at the bottom of the reaction evaporator 1 is 105°C, and the temperature at the top of the reaction evaporator 1 is 93°C. The temperature at the bottom of the distillation tower 8 is 93° C., and the temperature at the top of the rectification tower 8 is 78° C. Trimethylamine escapes evenly. The concentration of trimethylamine recovered is 45%, and the concentration of trimethylamine in the raffinate is 0.35%.

Embodiment 4

[0032]Embodiment 4: in continuous distillation process, in 5000L reaction evaporator 1, add trimethylamine waste water continuously, trimethylamine concentration is 5-17% and dosage 1m3 / h, then continuously add 30% liquid caustic soda, The dosage of 30% liquid caustic soda is 1.5L / h, the pH of the adjusted solution is about 9, the temperature at the bottom of the reaction evaporator 1 is 115°C, and the temperature at the top of the reaction evaporator 1 is 96°C. The temperature at the bottom of the distillation tower 8 is 96° C., and the temperature at the top of the rectification tower 8 is 94° C. Trimethylamine escapes evenly. The concentration of trimethylamine recovered is 45%, and the concentration of trimethylamine in the raffinate is 0.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com