Production method of high-purity vinylidene fluoride monomers

A vinylidene fluoride monomer technology, applied in the production of high-purity vinylidene fluoride monomer, can solve the problems of high product consumption, easy enrichment, waste of equipment investment, etc., to reduce the number of closed cycles and reduce system energy The effect of consumption and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

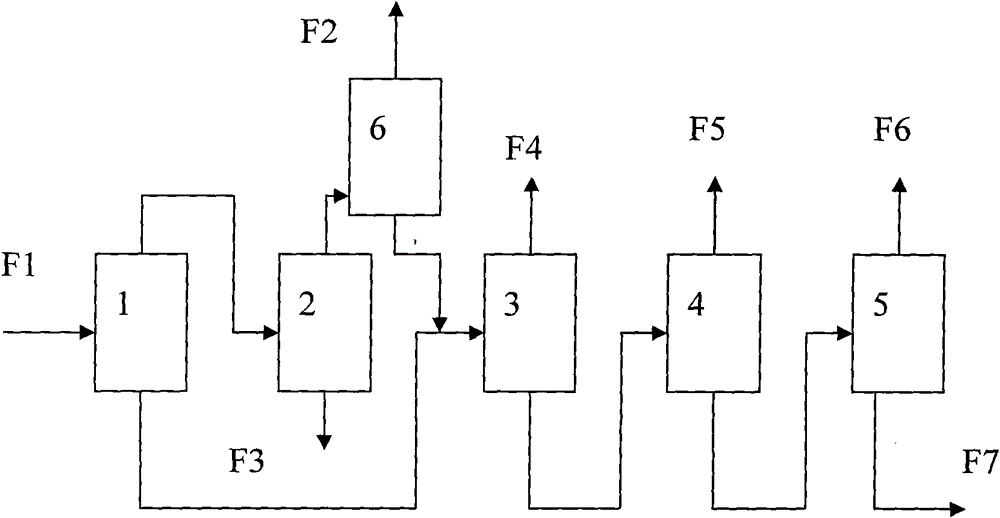

[0036] Embodiment: technical process such as figure 1 shown.

[0037] 1. Product purification process steps

[0038] 1. Dehigher tower: separation of high boilers

[0039] The cracked gas F1 enters the de-higher tower 1 to remove the high-boilers. Under the conditions of 1.3Mpa pressure, tower top temperature -19~-17°C, and tower kettle 19-25°C, the high-boilers are removed, and the separated high-boilers enter VDF concentration recovery tower 3. Vinylidene fluoride and light components enter the finished product distillation column 2.

[0040] 2. Finished distillation column: remove light components and produce high-purity vinylidene fluoride

[0041] Finished product rectification tower 2 rectifies the material under the conditions of 1.2Mpa pressure, tower top temperature -21~-20℃, tower bottom temperature -23~-22℃, and the light components in the material are discharged from the tower top into the light component concentration Tower 6, the bottom of the tower produces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com