A method for recovering light hydrocarbons from natural gas and oilfield associated gas

A technology for oilfield associated gas and natural gas, applied in the field of separation of light hydrocarbons from natural gas and oilfield gas, can solve the problems of inconvenient starting and parking, less light hydrocarbons and high material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

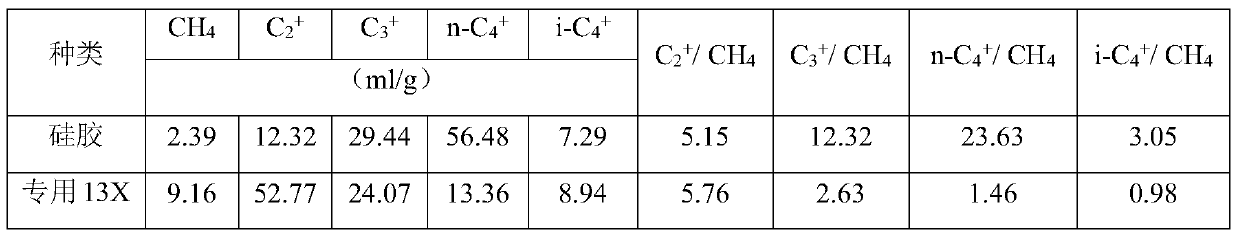

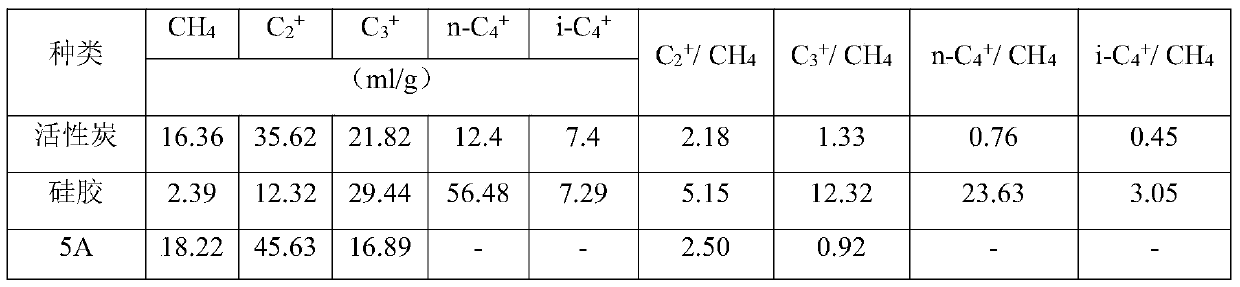

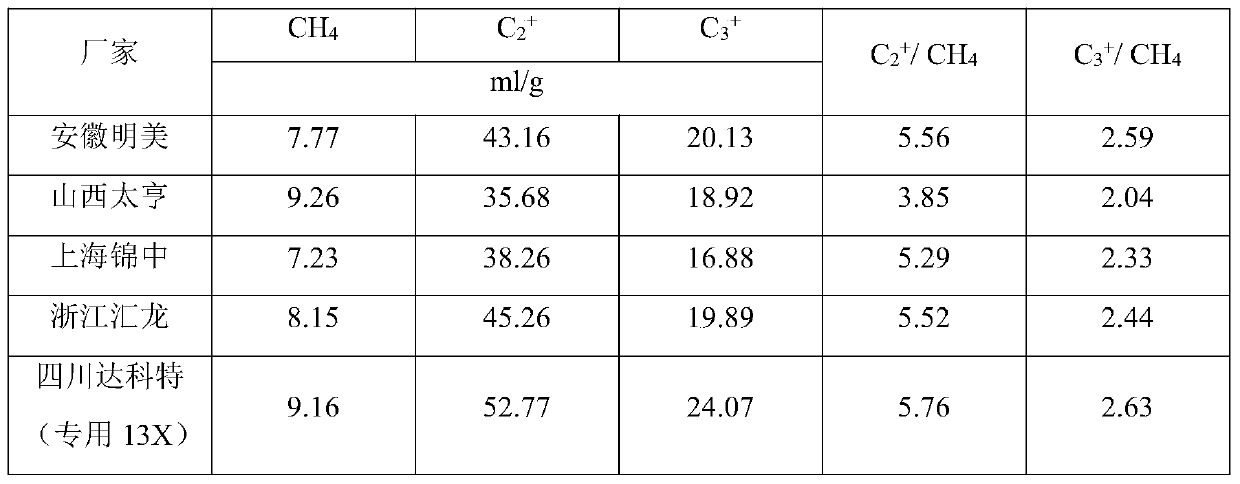

[0049] Using pressure swing adsorption technology, silica gel and special 13X adsorbent are used to absorb and desorb ethane and alkanes above ethane in natural gas and oil field gas; the adsorbent adopts composite packing method, silica gel is installed in the lower part of the adsorption tower, and special 13X adsorption is used The agent is installed in the upper section of the adsorption tower, and the filling ratio of silica gel and special 13X adsorbent is 1:2.15 (weight ratio).

[0050] The components and mass ratio of the special 13X adsorbent are: 13X raw powder: kaolin: attapulgite: carboxymethyl cellulose=100:18:2:0.3.

[0051] The number of adsorption towers in the pressure swing adsorption process is 4, and each adsorption tower undergoes the processes of adsorption, pressure equalization, reverse pressure drop, vacuum desorption, pressure equalization, and tail gas adsorption in one cycle; the adsorption pressure is 0.4MPa (G), vacuum desorption pressure -0.08MPa...

specific Embodiment 2

[0053] Using pressure swing adsorption technology, silica gel and special 13X adsorbent are used to absorb and desorb ethane and alkanes above ethane in natural gas and oil field gas; the adsorbent adopts composite packing method, silica gel is installed in the lower part of the adsorption tower, and special 13X adsorption is used The agent is installed in the upper section of the adsorption tower, and the filling ratio of silica gel and special 13X adsorbent is 1:0.56 (weight ratio).

[0054] The components and mass ratio of the special 13X adsorbent are: 13X raw powder: kaolin: attapulgite: carboxymethyl cellulose=100:15:5:0.5.

[0055] The number of adsorption towers in the pressure swing adsorption process is 6, and each adsorption tower undergoes the processes of adsorption, pressure equalization, reverse pressure drop, vacuum desorption, pressure equalization, and adsorption tail gas boost in one cycle; adsorption The pressure is 1.6MPa(G), the vacuum desorption pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com