Continuous process and device for the separation of benzyl chloride regular packing column

A technology of separation device and benzyl chloride gauge, which is applied in the direction of distillation purification/separation, chemical instruments and methods, organic chemistry, etc., can solve problems such as product quality problems, unqualified automatic control hardware, poor corrosion resistance, etc. The effect of low internal space occupation, reduced energy consumption, and small welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below according to accompanying drawing:

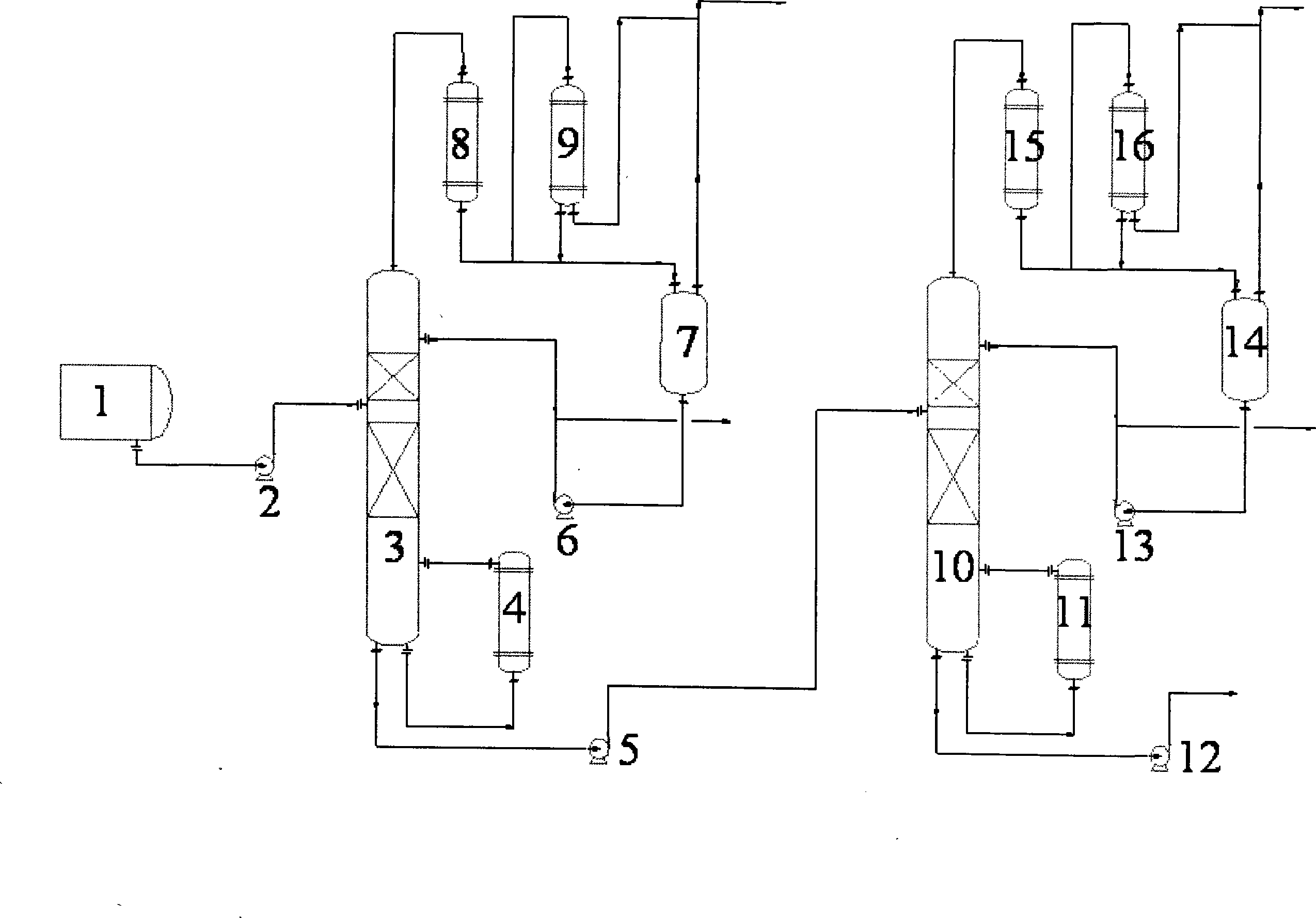

[0023] As shown in FIG. 1 , the toluene rectification tower 3 and the benzyl chloride rectification tower 10 are both structured packing towers, and the structured packings are orifice metal corrugated packings. The toluene rectification tower 3 is provided with a secondary condenser, that is, the toluene rectification tower condenser-1 (8) and the toluene rectification tower condenser-2 (9). , one end is connected to the toluene rectification tower reflux tank 7, the reflux tank is connected to a vacuum device, the lower end is connected to the toluene rectification tower reflux pump 6, and the toluene rectification tower 3 bottom is provided with a toluene rectification tower reboiler 4. Benzyl chloride rectification tower 10 is provided with secondary condenser, namely benzyl chloride rectification tower condenser-1 (15), benzyl chloride rectification tower condenser-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com