Ultra-centrifugal dust remover adopting spraying device

A spray device and ultra-centrifugation technology, applied in the combination device, separation method, dispersed particle separation, etc., can solve the problems of large equipment and high requirements, and it is difficult for ordinary equipment to remove dust with extremely small particle size, etc., and achieve the spray angle range. Large, improve dust removal efficiency, improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

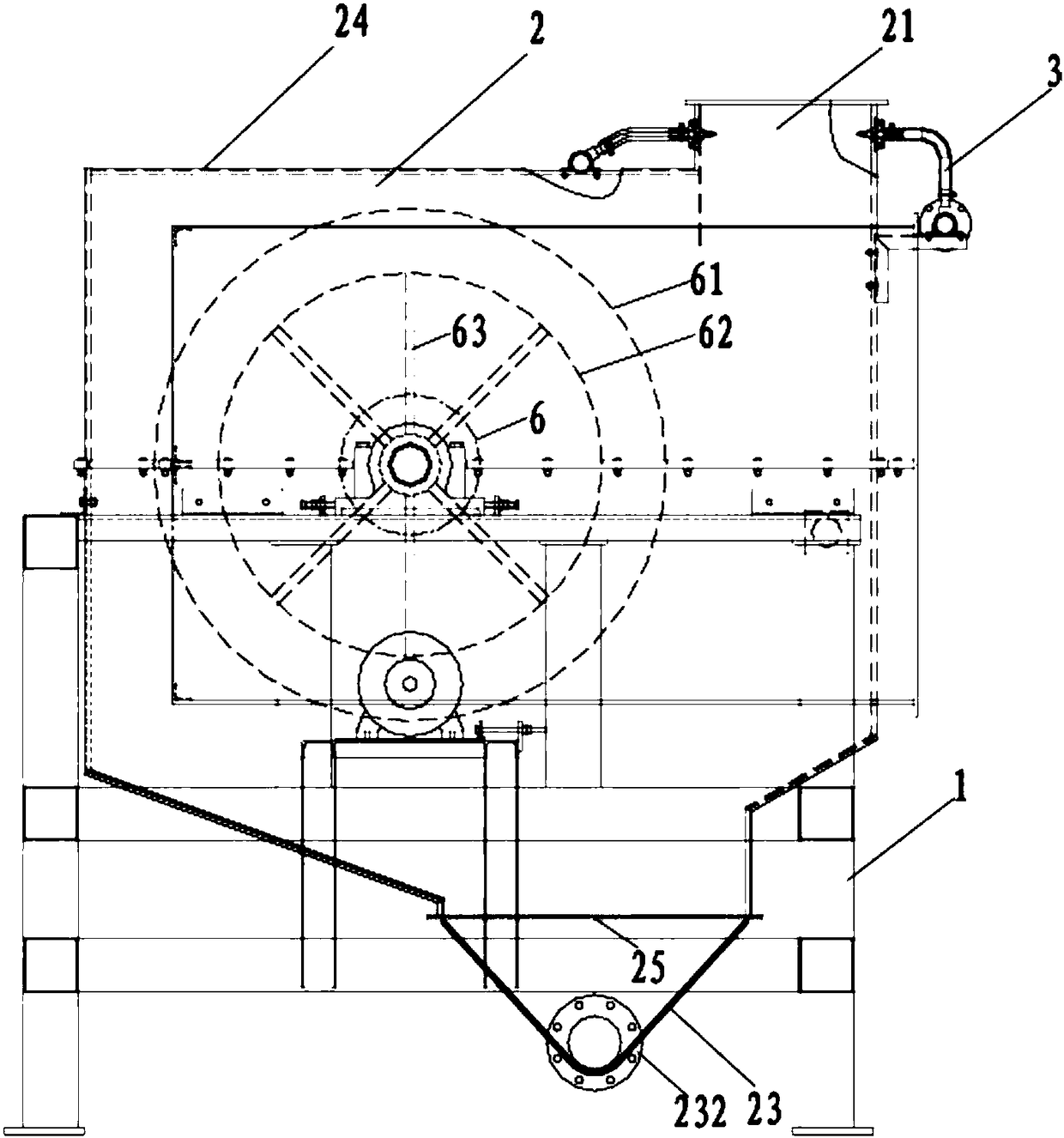

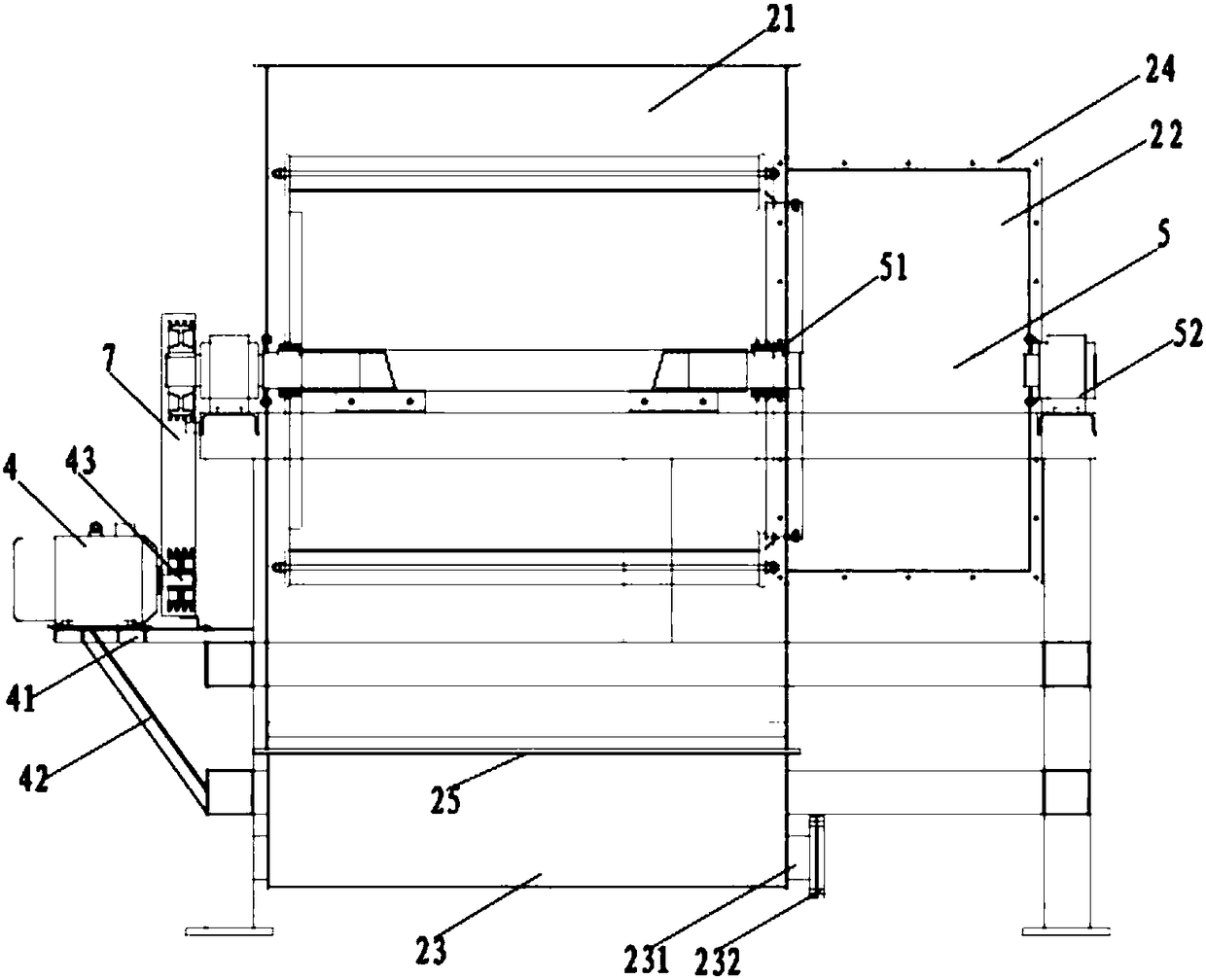

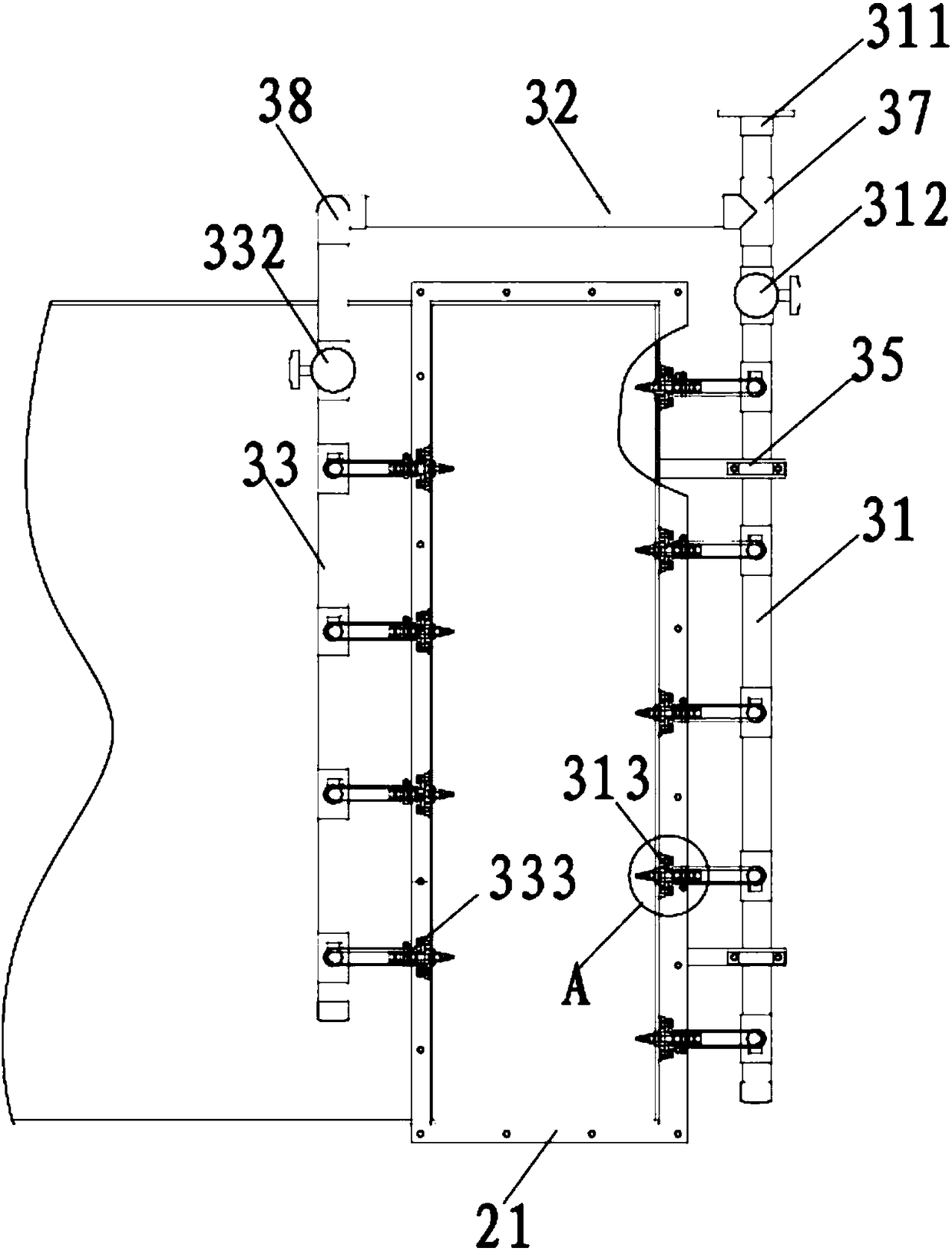

[0018] The reference signs in the accompanying drawings of the description include: frame 1, box body 2, air inlet 21, air outlet 22, sink 23, drain 231, end cover 232, protective cover 24, water seal tank 25, spray Device 3, the first water pipe 31, the main control valve 311, the first control valve 312, the first nozzle 313, the second water pipe 32, the third water pipe 33, the second control valve 332, the second nozzle 333, the connecting plate 35. Nozzle 36, two-way pipe joint 37, right-angle pipe joint 38, motor 4, motor mounting plate 41, inclined support plate 42, output shaft 43, rotating shaft 5, sealing ring 51, bearing seat 52, rotor 6, the first Filter screen 61 , second filter screen 62 , blade 63 , transmission device 7 .

[0019] refer to figure 1 and figure 2 , an ultracentrifugal dust collector using a spray device in the present invention, compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com