Food waste raw material receiving comprehensive treatment apparatus

A technology for comprehensive treatment and kitchen waste, applied in packaging, solid waste removal, etc., can solve the problems of locking screw operation, clogging of the discharge end of bagged waste, inconvenient maintenance and maintenance, etc., to prevent motor damage, avoid The effect of uneven discharge and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

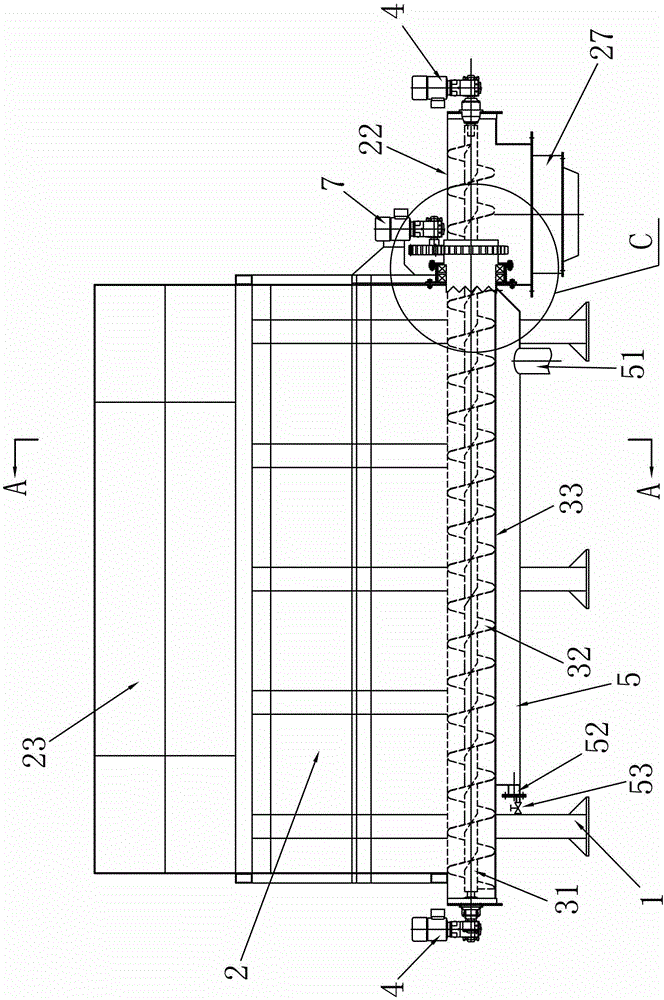

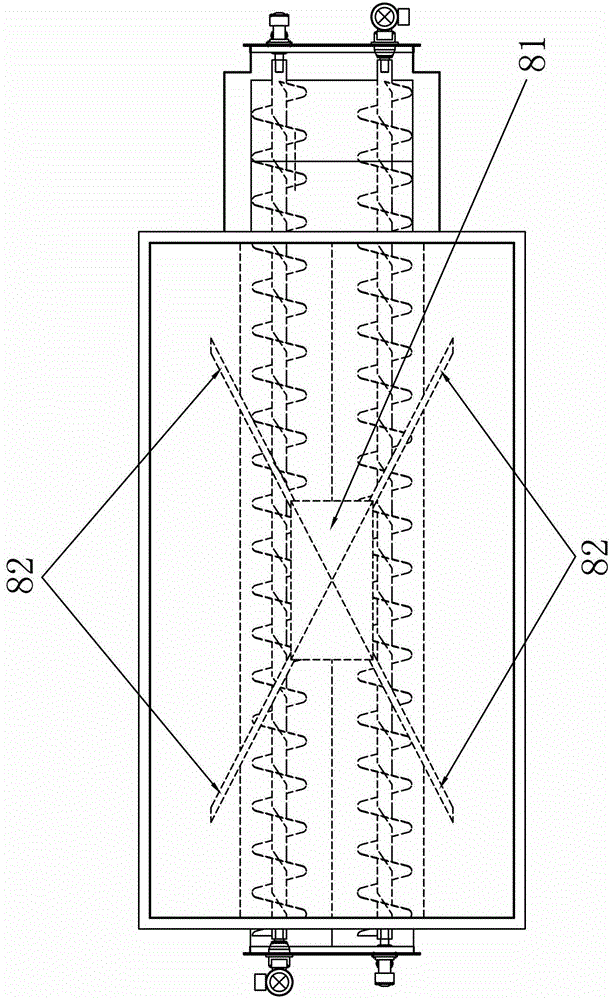

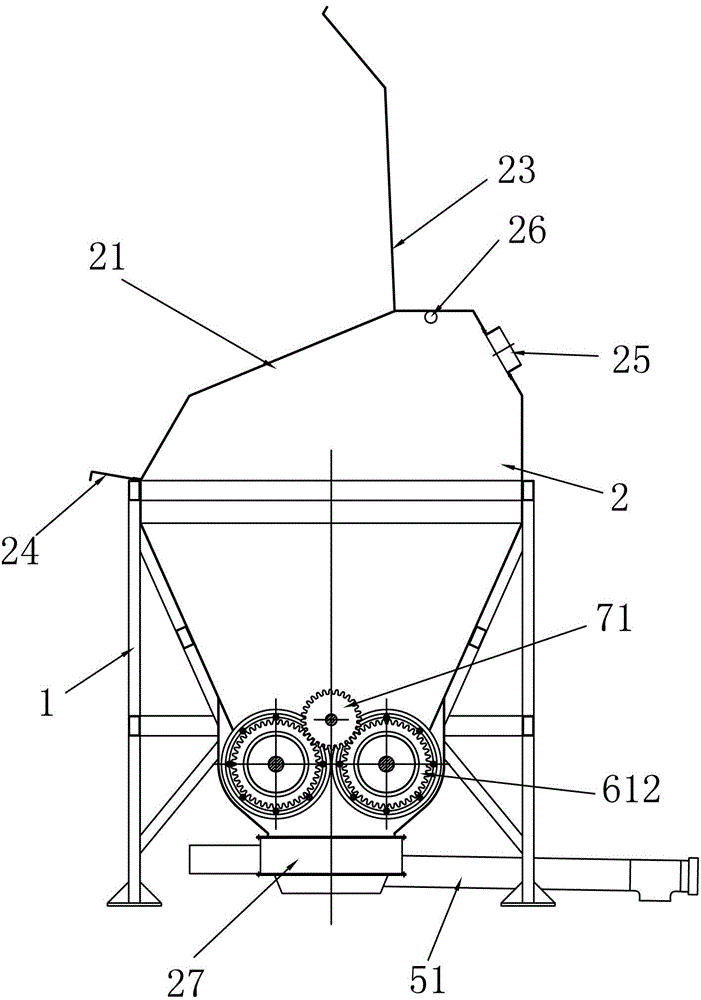

[0023] Such as figure 1 Shown is the first embodiment of the kitchen waste raw material receiving comprehensive treatment device of the present invention, see also figure 2 with image 3 , the frame 1 is fixed with a receiving bin body 2, the upper part of the receiving bin body 2 is provided with a feed port 21, and the lower part of the receiving bin body 2 is provided with two screw conveying and separating mechanisms, and the screw conveying and separating mechanisms include screw shafts arranged coaxially with each other 31. The spiral blade 32 and the arc-shaped pocket 33, the spiral blade 32 is fixedly connected to the screw shaft 31, the arc-shaped pocket 33 is arranged below the spiral blade 32, and the upper part of the arc-shaped pocket 33 communicates with the receiving bin body 2, After the garbage enters from the feed port 21, it will arrive at the screw conveying separation mechanism due to gravity. One end of the screw shaft 31 and the screw blade 32 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com