Device for protecting air preheater against blockage by combining sound wave and hot air

An air preheater, the first sound wave technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, combustion product treatment, etc., can solve the problems of unresolved blockage, high running resistance, high energy consumption, etc., to overcome the prevention and control Incomplete plugging technology, improve mass transfer and heat transfer efficiency, and make use of the effect of mass transfer and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

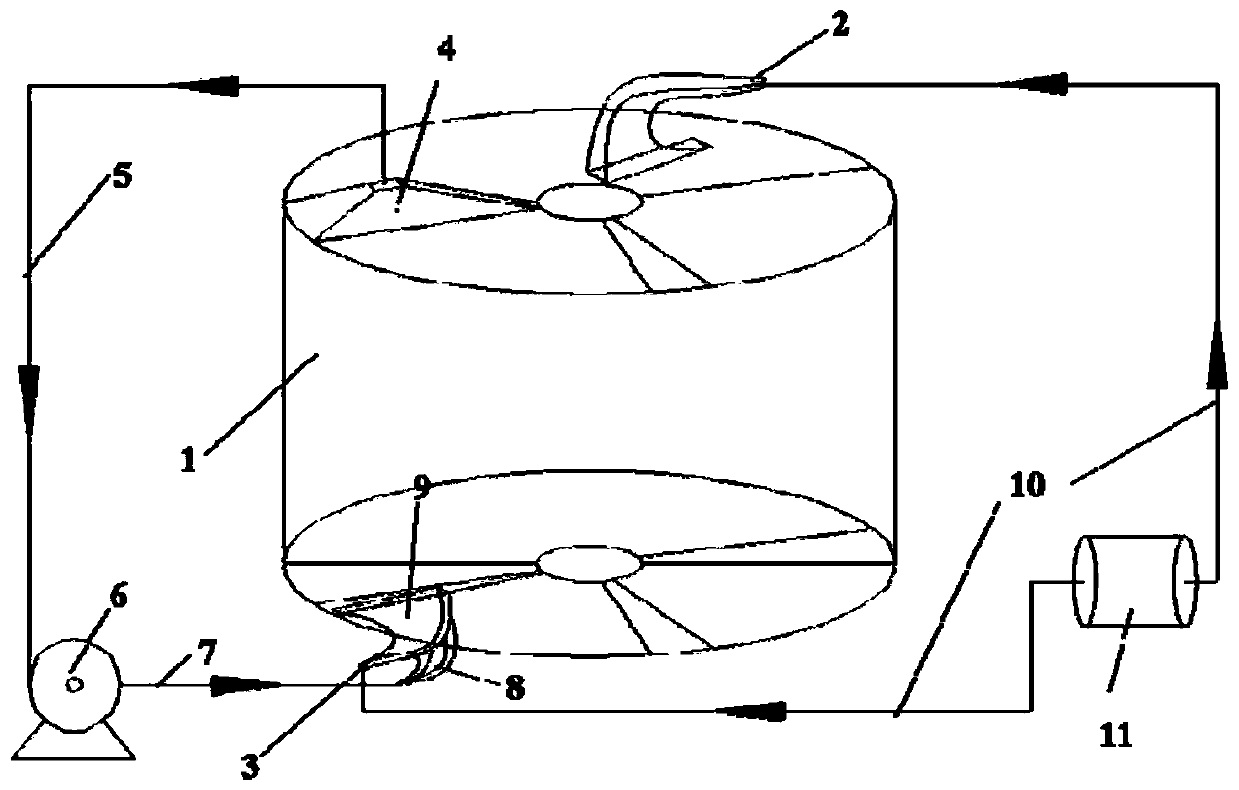

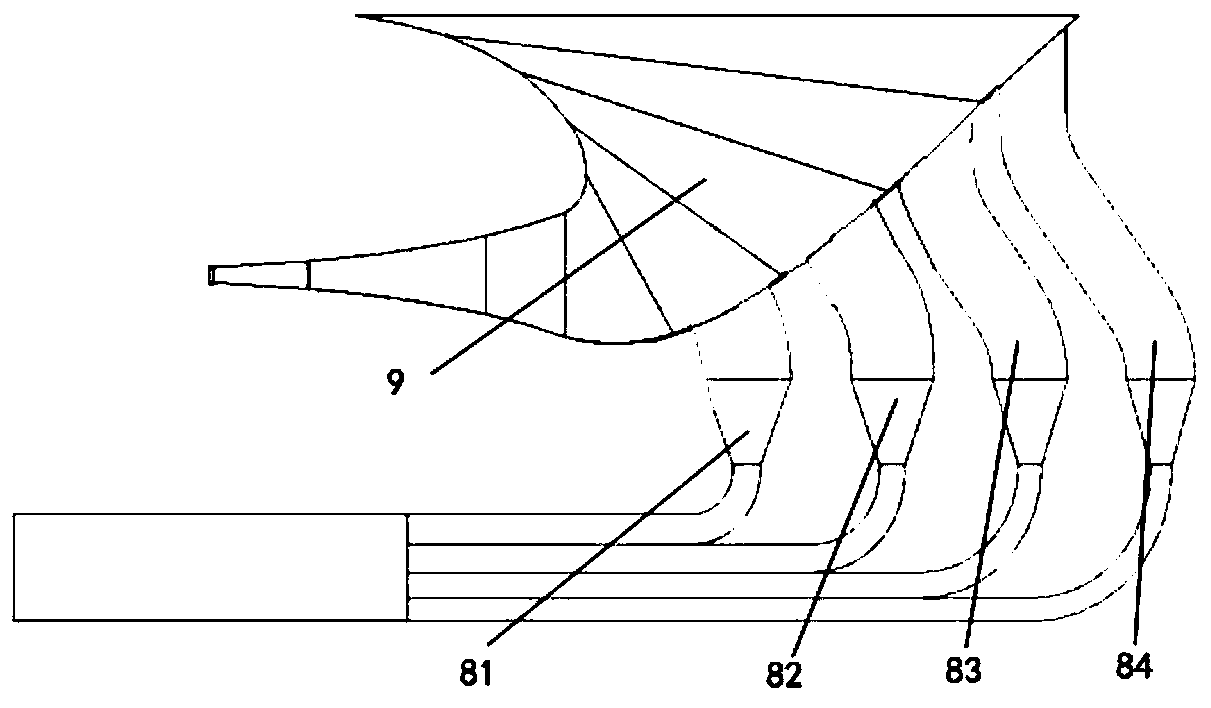

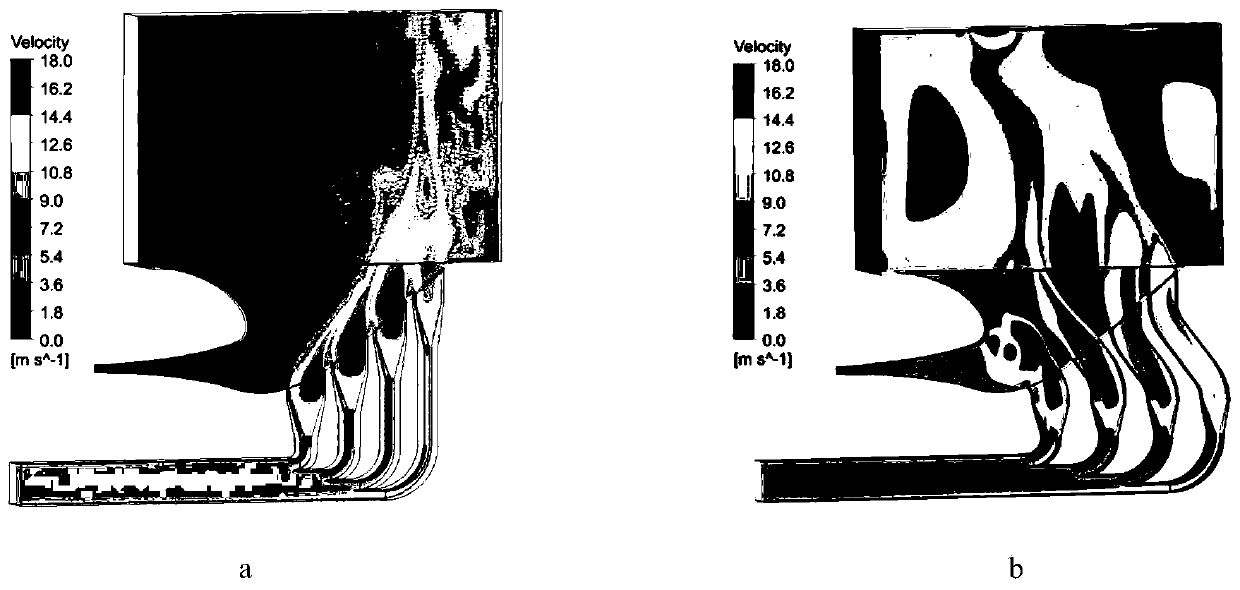

[0033] Such as figure 1 As shown, this embodiment provides a device based on the combination of sound waves and hot air to prevent air preheater blockage, including a three-chamber rotary air preheater, on the top side of the three-chamber rotary air preheater Set the first sonic soot blower 2, set the air leakage side collection cover 4 on the other side of the top of the three-segment rotary air preheater, and set an inlet cover at the bottom of the three-segment rotary air preheater The air-collecting hood 9 and the air-intake air-collecting hood 9 are provided with a second acoustic soot blower 3, and the air leakage side collection hood 4 is connected to the input end of the circulation fan 6 through the air leakage side collection pipe 5, and the output end of the circulation fan 6 passes through the circulation The flue gas pipe 7 is connected to the circulating flue gas nozzle 8 , and the circulating flue gas nozzle 8 is connected to the air intake hood 9 . Through th...

Embodiment 2

[0043] This embodiment is an example of using the device provided in Embodiment 1 for a certain coal-fired power plant, wherein the air preheater sound wave and hot air blockage prevention device of the coal-fired power plant includes a three-chamber rotary air preheater, and the air preheating load is 300MW unit, the diameter of the rotor is 15000mm, the rotation direction of the rotor: flue gas→primary air→secondary air, the flow angle of the flue gas compartment is 165°, the circulation angle of the circulation compartment is 15°, and the flow angle of the secondary air compartment is 100°, the circulation angle of the primary air distribution chamber is 80°, and the flue gas volume is 1.12 million m 3 / h, the flue gas inlet temperature is 380°C; the primary air volume is 70,000 m 3 / h, the primary air inlet temperature is 30°C; the secondary air volume is 150,000 m 3 / h, the secondary air inlet temperature is 30°C; the circulating air volume is 3% of the flue gas leakage ...

Embodiment 3

[0045] This example adopts the device provided in Example 1. A coal-fired power plant air preheater combined sound wave and hot air blockage prevention device includes a three-chamber rotary air preheater. The air preheating load is a 600MW unit, and the rotor diameter is 15000mm. Rotation direction: flue gas→primary air→secondary air, the flow angle of the flue gas compartment is 165°, the circulation angle of the circulation partition compartment is 15°, the circulation angle of the secondary air compartment is 120°, and the circulation angle of the primary air compartment The angle is 60°, and the flue gas volume is 2.4 million m 3 / h, the flue gas inlet temperature is 400°C; the primary air volume is 150,000 m 3 / h, the primary air inlet temperature is 35°C; the secondary air volume is 300,000 m 3 / h, the secondary air inlet temperature is 35°C; the circulating air volume is 4% of the flue gas leakage rate, and the air volume is 96,000 m 3 / h, the circulating fan circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com