Automatic control device for soot blower in SCR denitration process, and control method of control device

A technology of automatic control device and soot blower, which is applied to the program control and electrical program control of the sequence/logic controller, and can solve problems such as blockage and inability to control the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in combination with specific embodiments.

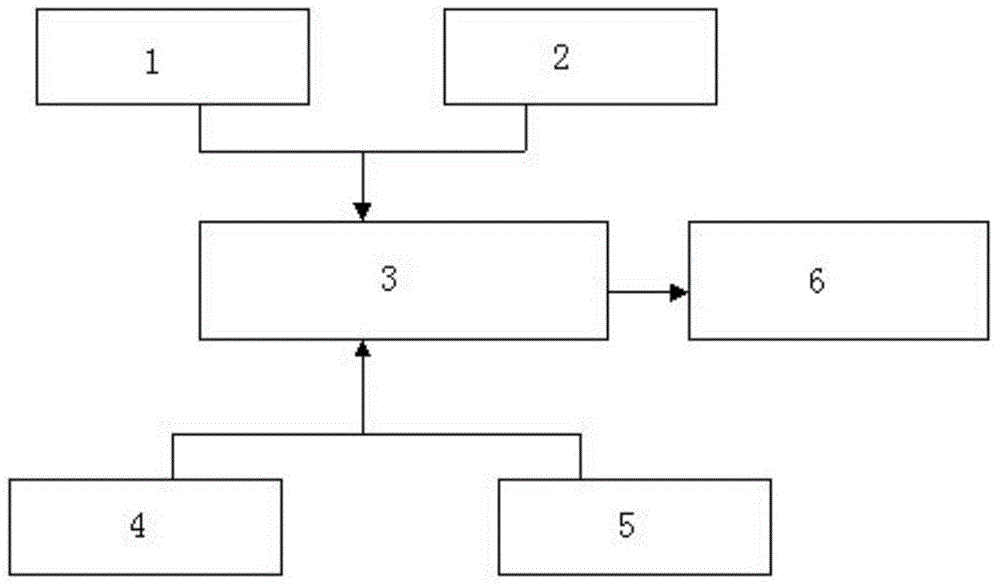

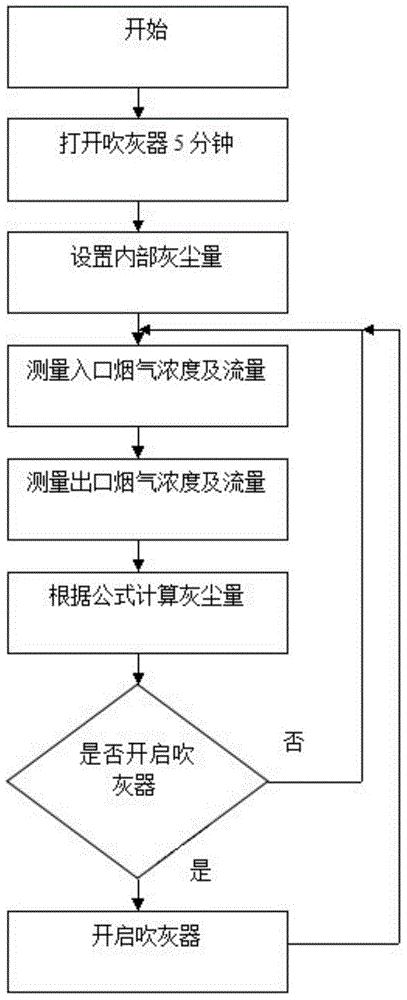

[0025] The system of the present invention is as figure 1 As shown, it includes an inlet particle concentration sensor 1, an inlet gas flow sensor 2, a PLC processor 3, an outlet particle concentration sensor 4, an outlet gas flow sensor 5 and an ultrasonic sootblower 6;

[0026] The inlet particle concentration sensor 1 and the inlet gas flow sensor 2 respectively detect the particle concentration and gas flow of the inlet gas, and send the detection data to the PLC processor 3;

[0027] The outlet particle concentration sensor 4 and the outlet gas flow sensor 5 respectively detect the particle concentration and gas flow of the outlet gas, and send the detection data to the PLC processor 3;

[0028] The PLC processor 3 judges whether the amount of internal dust is greater than the set value, and when the amount is greater than the set value, the ultrasonic soot blower 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com