Automatic ash removing device of belt type sludge dryer and control method thereof

A technology of automatic ash cleaning and sludge drying, applied in separation methods, chemical instruments and methods, dewatering/drying/concentrating sludge treatment, etc., can solve the problems of frequent replacement of filter bags, reduce maintenance and operating costs, etc. Level of automation, improved airflow, well-organized results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

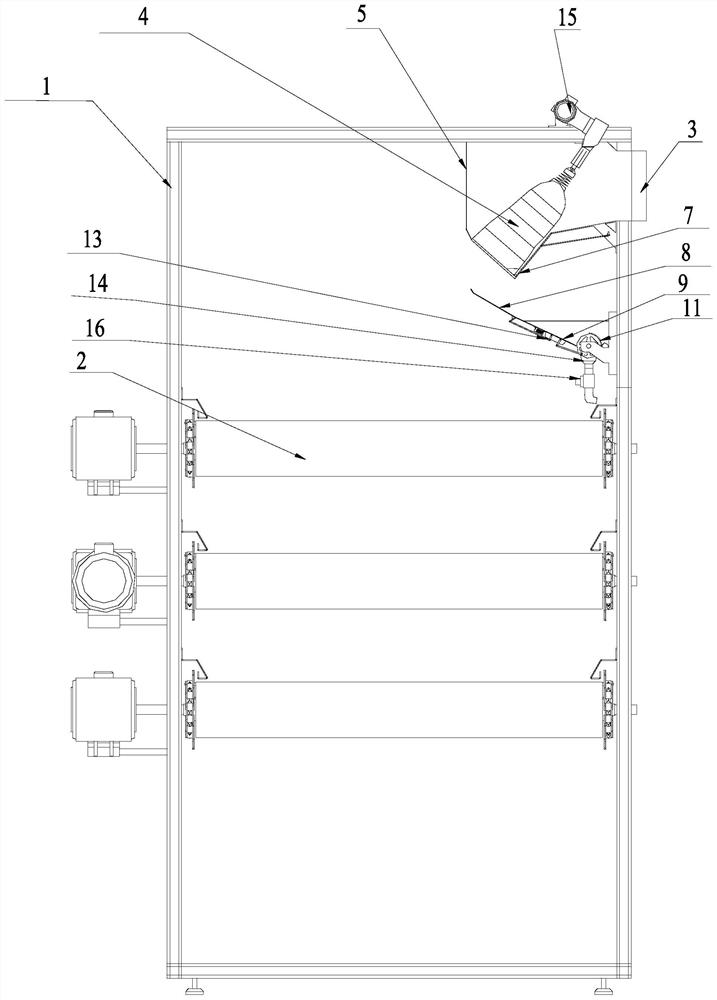

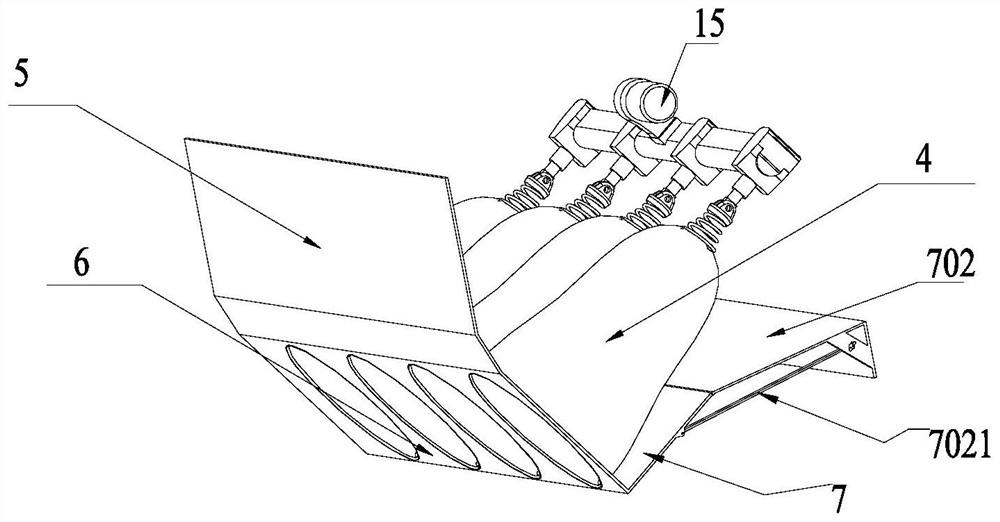

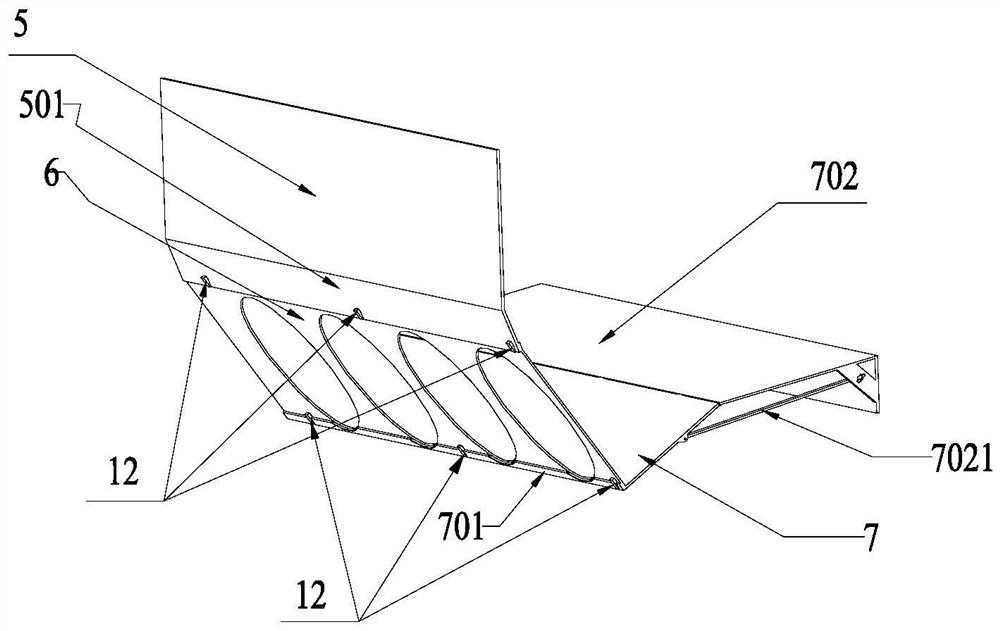

[0037] Such as figure 1 As shown, the present embodiment provides an automatic cleaning device for a belt sludge dryer. The dryer includes a box body 1, a mesh belt sludge conveyor 2 and a control system (not shown in the figure). The sludge conveyor 2 is installed inside the box 1, the sludge dryer is electrically connected to the control system, and the side wall of the box 1 is provided with a return air outlet 3; the dryer also includes an automatic cleaning machine. Ash device, the automatic dust removal device is electrically connected with the control system, the automatic dust removal device is located above the mesh belt sludge conveyor 2, and is located outside the air return port 3, and the box body 1 is divided into a negative pressure chamber and a positive pressure chamber; the automatic dust removal device includes a filter mechanism, a collection mechanism, a mechanical shaker 15 and an inductor, and the collection mechanism is located below the filter mechanis...

Embodiment 2

[0061] Such as Figure 8 As shown, the working sequence and process of the automatic dust removal device and components in this embodiment are the same as those in Embodiment 1. The difference is that the duration of action of the mechanical shaker 15 in the control method of this embodiment can be manually set in the control system. , without the control system judging whether the tensile stress value measured by the strain gauge 12 reaches a certain lower threshold before stopping the mechanical shaker 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com