Device with thermoelectric power generation and heat dissipation functions and thermoelectric power generation method

A technology of thermoelectric power generation and thermoelectric power generation modules, which is applied in the direction of generators/motors, circuits, electrical components, etc., can solve the problems of no obvious help in airflow organization optimization, inability to efficiently use thermoelectric power generation, and difficulty in quickly draining fluids, etc., to achieve improved Heat dissipation effect, small resistance, easy management and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

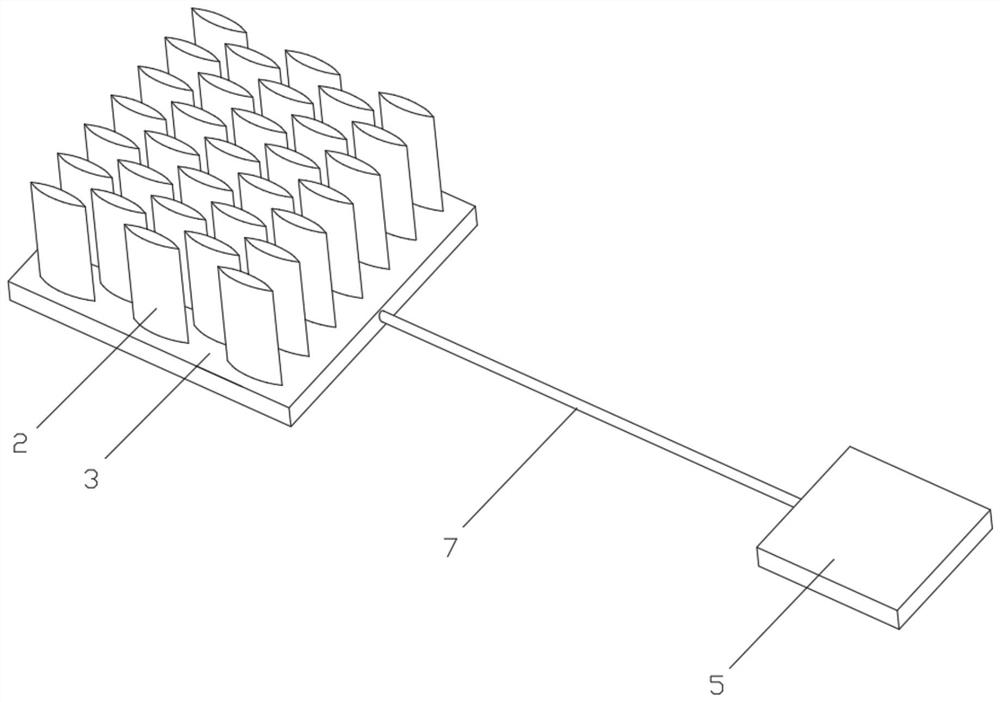

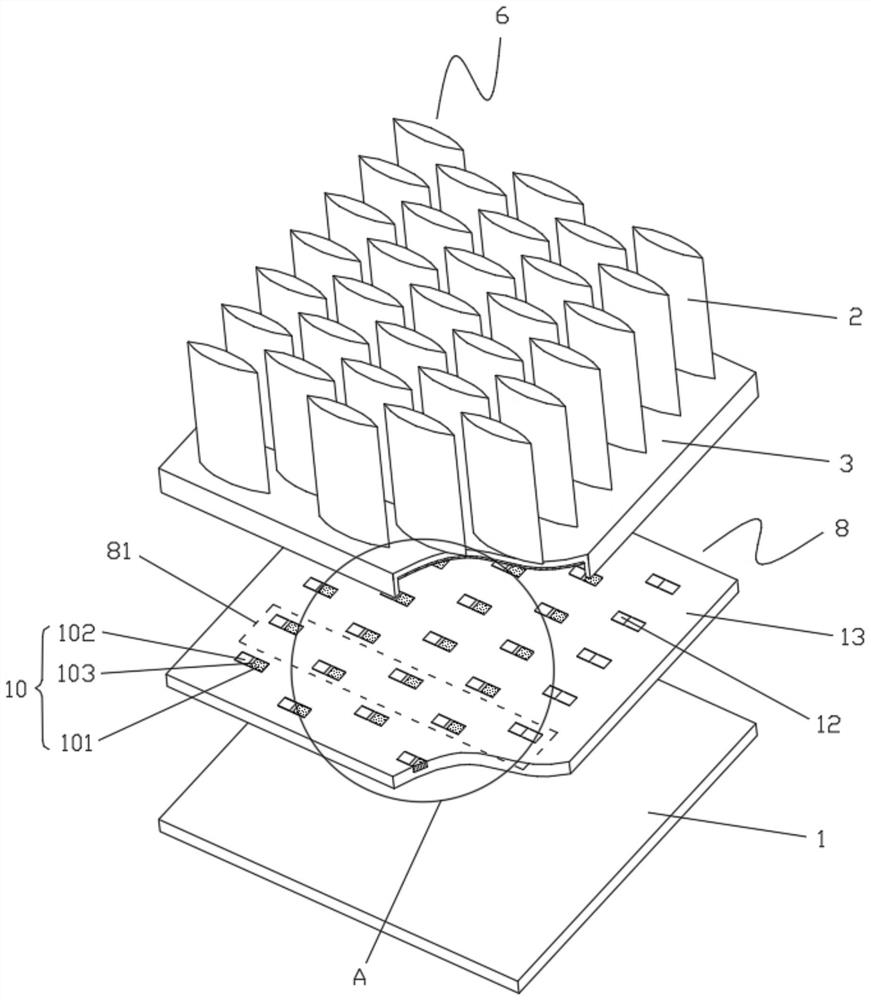

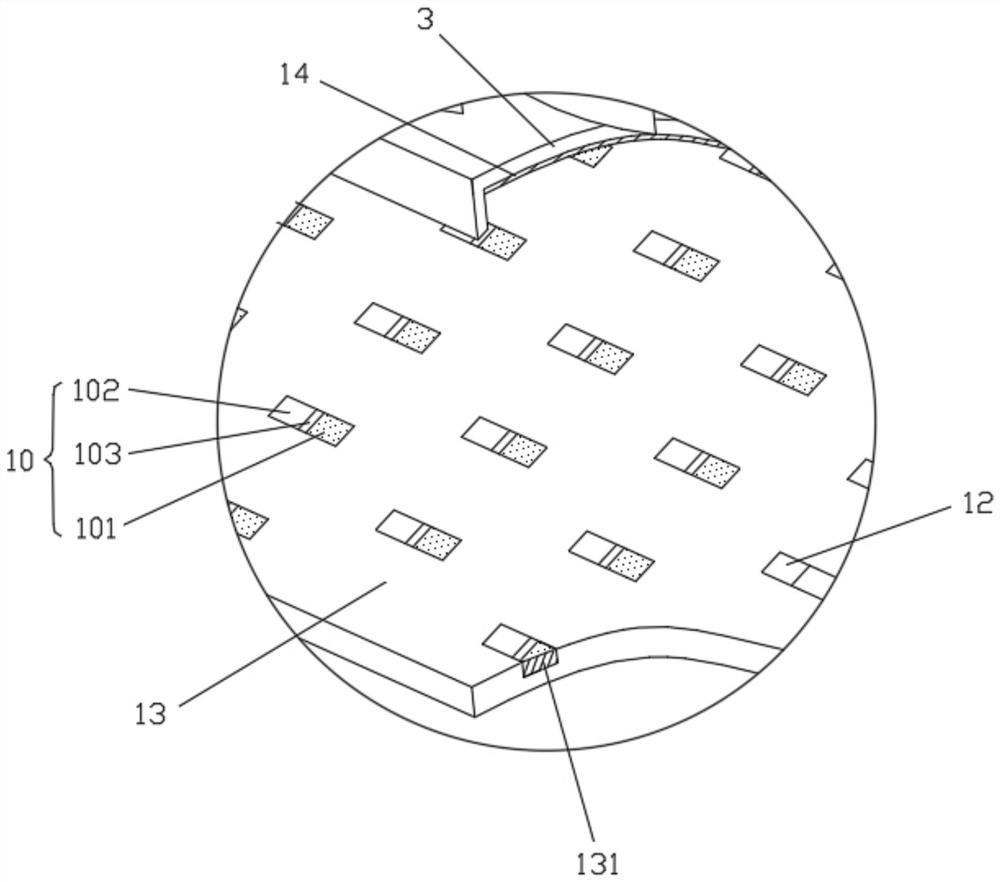

[0036] refer to Figure 1 to Figure 6 , a device with thermoelectric power generation and heat dissipation functions of the present invention includes a high-temperature end heat conduction module, a low-temperature end heat conduction module, a short-distance thermoelectric power generation module and a long-distance thermoelectric power generation module.

[0037] The heat conduction module at the high temperature end includes a heat conduction layer 1 at the high temperature end for abutting against a high temperature object, and a set of cooling ribs arranged on the heat conduction layer 1 at the high temperature end. The heat conduction layer 1 at the high temperature end is a heat conduction silica gel layer. The heat dissipation fin group includes a plurality of heat dissipation fins 2, the heat dissipation fins 2 are cylinders with a streamlined cross section, and the plurality of heat dissipation fins are arranged in a rhombus staggered manner, and the heat dissipatio...

Embodiment 2

[0044] refer to Figure 7 and Figure 8 , The difference between this embodiment and Embodiment 1 is that: the metal insulating substrates 13 of the hot end module 8 and the cold end module 9 are provided with several wire channels 15 for embedding wires 7 . Several heat dissipation fins 2 of the heat dissipation fin group are connected as a whole through an insulating heat conducting plate, and the heat dissipation fins 2 are bonded to the insulating heat conducting plate. The metal insulating substrate 13 of the hot end module 8 is closely connected between the high temperature end heat conducting layer 1 and the insulating heat conducting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com