Combined soot-blowing system

A soot blowing system and soot blower technology are applied in the treatment of combustion products, combustion methods, removal of solid residues, etc., which can solve hidden dangers affecting furnace efficiency, safe operation of heating furnaces, and can not well meet soot blowing requirements, etc. problem, to achieve the effect of improving furnace efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

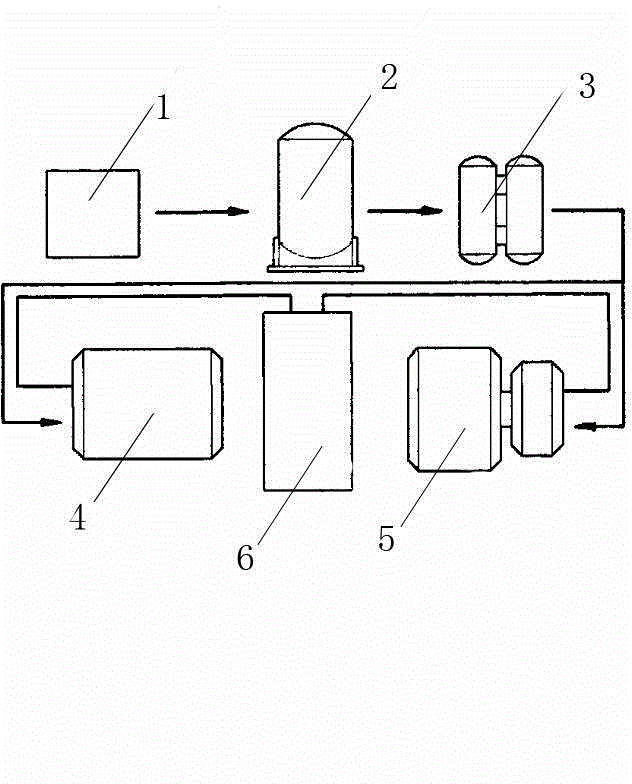

[0012] A combined soot blowing system according to the present invention includes an air compressor 1, an air storage tank 2, a dryer 3 and a heating furnace 6 connected in sequence, the heating furnace 6 is provided with a convection chamber, and the sonic soot blower 44 is arranged on The side of the convection chamber and the pneumatic rotary soot blower 5 are arranged on the front of the convection chamber. The combined soot blowing system also includes a control device, which is connected with the sonic soot blower 4 and the pneumatic rotary soot blower 5 respectively. connect.

[0013] When in use, first turn on the sonic soot blower 4 to crush the coke on the furnace tube for 30 minutes. During the period, the coke slag on the convection furnace tube is broken into powder, then turn off the sonic soot blower 4 and start the pneumatic rotation Type soot blower 5 makes the crushed powder out of the heating furnace 6 along with the furnace flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com