Method for manufacturing smokeless incombustible temperature-resistant tetrafluoroethylene electric wire

A technology of polytetrafluoroethylene and its production method, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of insufficient density, insufficient smoothness, uneven thickness, etc., achieve enhanced voltage resistance performance, and simple production process , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

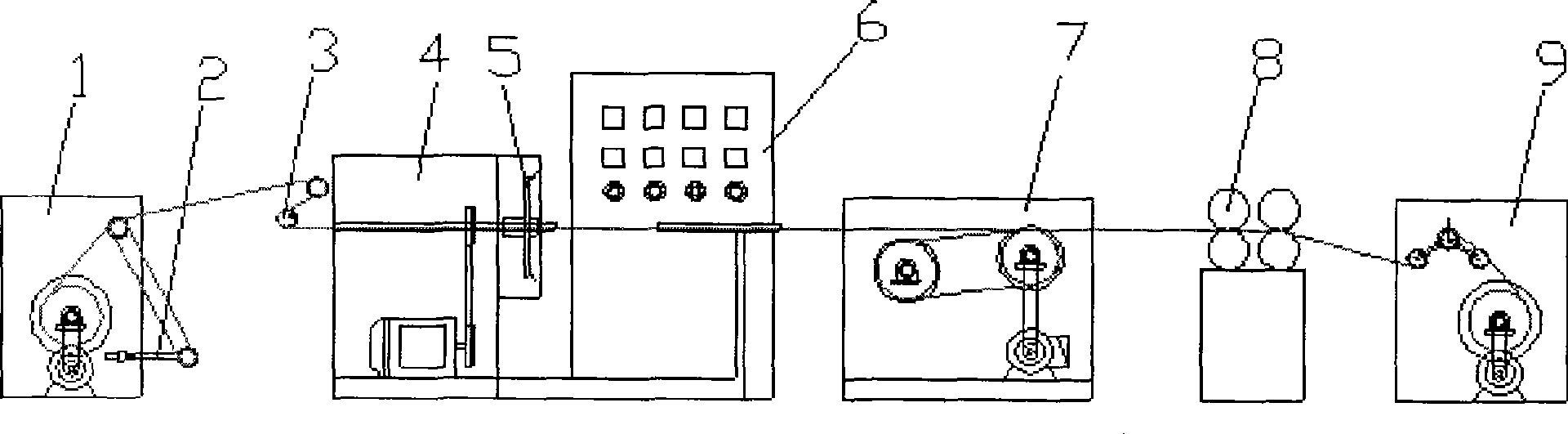

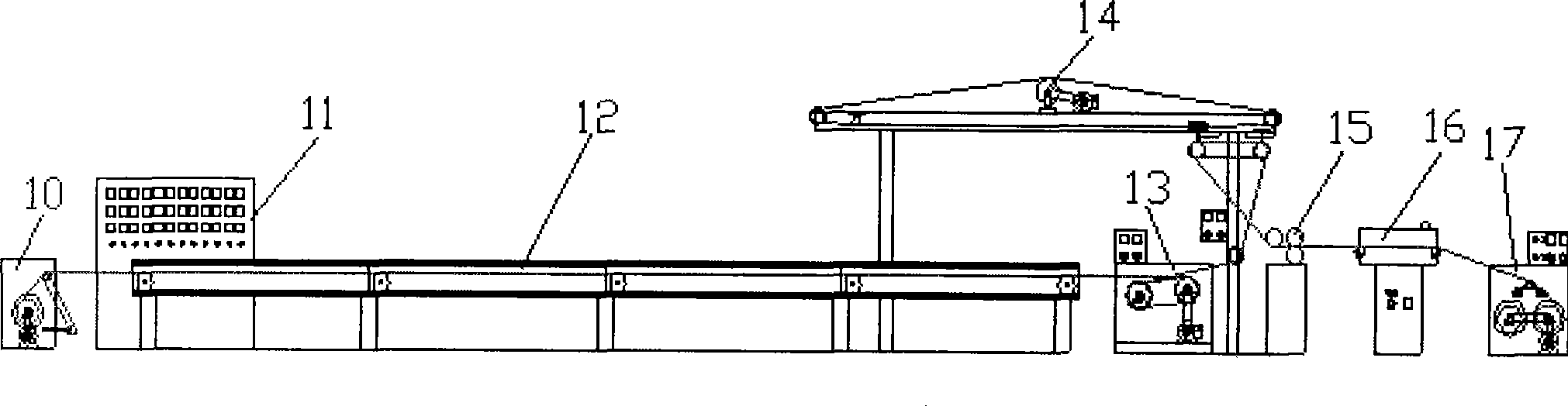

[0038] (1) Wrap the polytetrafluoroethylene colored raw material tape for winding and sintering on the bare wire. The polytetrafluoroethylene colored raw material tape for winding and sintering is wrapped on the nickel-plated copper stranded wire through the wrapping device, the wrapping angle is 30°, the overlapping rate is controlled at 100%, and the drawing speed is 200r / min. After the wrapping is completed, shaping is carried out to improve the compactness of the insulating layer and further improve the breakdown strength. The shaping temperature is 100°C.

[0039](2) Carry out sintering treatment. Sinter the wrapped bare wire through a sintering furnace, the sintering temperature is controlled at 380°C, the take-up speed is 200r / min, and the drawing speed is 200r / min.

Embodiment 2

[0041] (1) Wrap the polytetrafluoroethylene colored raw material tape for winding and sintering on the bare wire. The polytetrafluoroethylene colored raw material tape for winding and sintering is wrapped on the nickel-plated copper stranded wire through the wrapping device, the wrapping angle is 50°, the overlapping rate is controlled at 200%, the wrapping speed is 300r / min, the extraction 300r / min. After the wrapping is completed, shaping is carried out to improve the compactness of the insulating layer and further improve the breakdown strength. The shaping temperature for shaping is 200°C.

[0042] (2) Carry out sintering treatment. Sinter the wrapped bare wire through a sintering furnace, the sintering temperature is controlled at 400°C, the wire take-up speed is 300r / min, and the drawing speed is 300r / min.

Embodiment 3

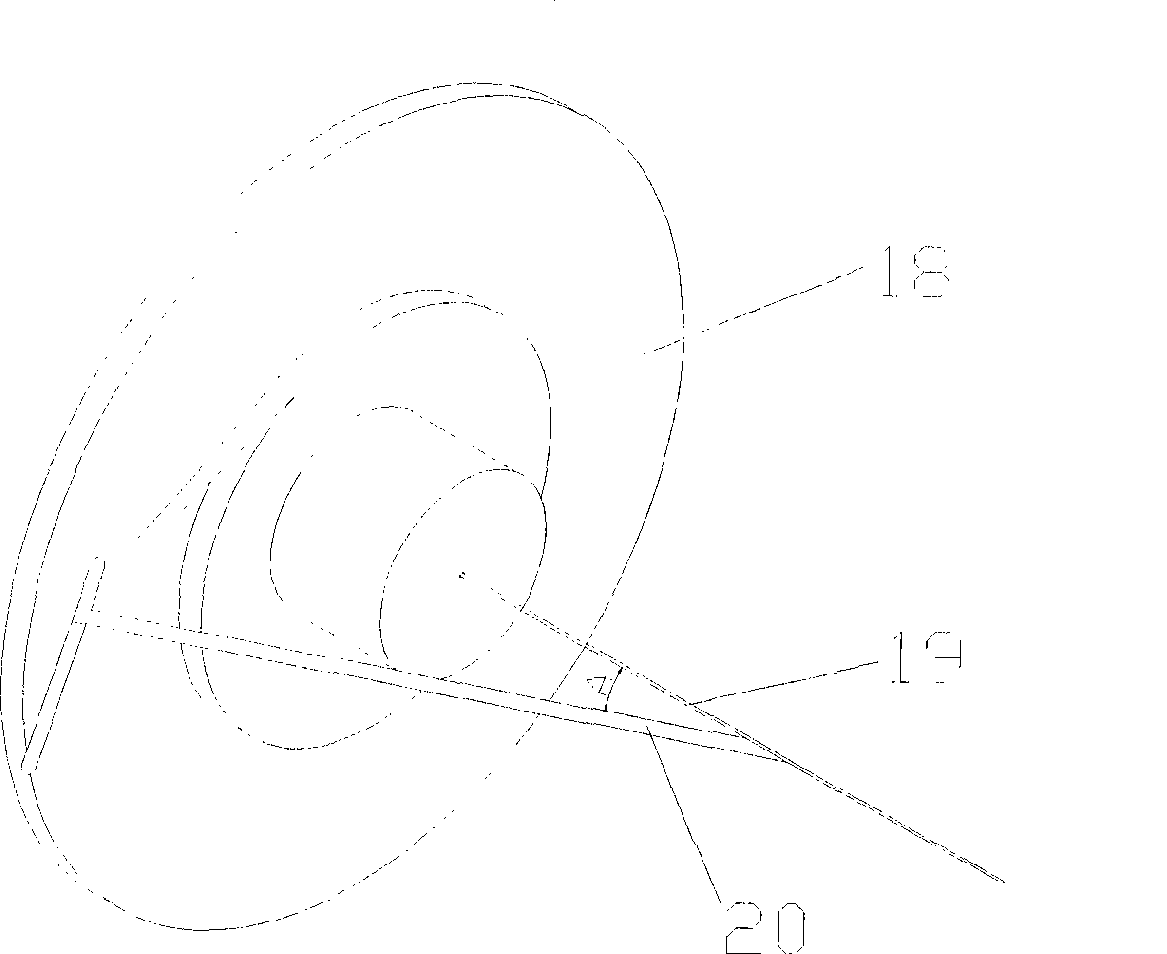

[0044] (1) Wrap the polytetrafluoroethylene colored raw material tape for winding and sintering on the bare wire. The bare wire is preferably nickel-plated copper stranded wire. After the copper is nickel-plated, it can prevent rust and aging, and can also greatly improve the strength, corrosion resistance and high temperature resistance of copper. The polytetrafluoroethylene colored raw material tape for winding and sintering is wrapped on the nickel-plated copper stranded wire through the wrapping device, the wrapping angle is 40°, the overlapping rate is controlled at 150%, the wrapping speed is 250r / min, the extraction 250r / min. After the wrapping is completed, shaping is carried out to improve the compactness of the insulating layer and further improve the breakdown strength. The shaping temperature for shaping is 150°C.

[0045] (2) Carry out sintering treatment. Sinter the wrapped bare wire through a sintering furnace, the sintering temperature is controlled at 390°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com