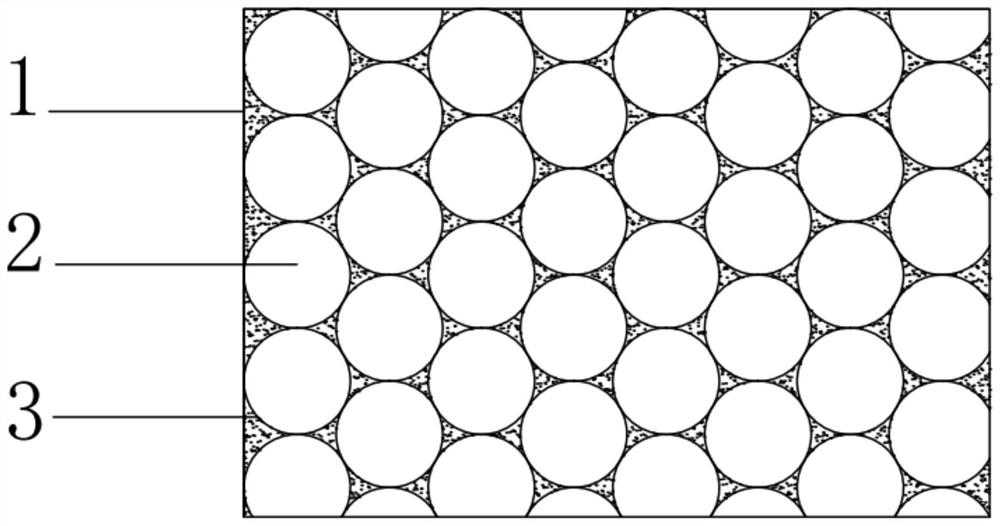

Inorganic composite polyphenyl A-grade insulation board and production method thereof

A technology of composite polyphenylene and production methods, applied in thermal insulation, chemical instruments and methods, ceramic molding machines, etc., can solve problems such as difficult completion of thermal insulation boards, falling off of thermal insulation layers, and insufficient ash-sticking ability, so as to eliminate fire hazards and keep thermal insulation The effect is improved and the heat preservation effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The production method of the inorganic composite polyphenylene grade A thermal insulation board described in this embodiment includes the following steps:

[0047] 1. Put the water and modifier into the mixing tank according to the proportion and stir for 10 minutes, then put the fireproof material 15#P.O425 cement into the mixing tank and stir for 5-10 minutes according to the proportion to obtain the cement-based inorganic slurry material;

[0048] The modifier adopts the following raw material formula: in parts by weight, it contains 100kg of 0# internal waterproofing agent, 64kg of 8# skeleton proppant, 140kg of 14# linking agent, 4kg of 16# suspension modifier, and 19# high-end reducing thermal conductivity. Coefficient material 1640kg, 20# reinforced internal health agent 50kg, 22# early strength stabilizer 2kg; the added amounts of the water, modifier and 15#P.O425 cement are respectively in weight fractions: water 470kg, modifier 200kg, 15#P.O425 cement 700kg. ...

Embodiment 2

[0057] The production method of the inorganic composite polyphenylene grade A thermal insulation board described in this embodiment includes the following steps:

[0058] 1. Put the water and modifier into the mixing tank according to the proportion and stir for 10 minutes, then put the fireproof material 15#P.O425 cement into the mixing tank and stir for 5-10 minutes according to the proportion to obtain the cement-based inorganic slurry material;

[0059] The modifier adopts the following raw material formula: in parts by weight, it contains 64kg of 8# skeleton proppant, 140kg of 14# linking agent, 4kg of 16# suspension modifier, 1740kg of 19# high-end thermal conductivity reducing material, 20# reinforcement Internal health agent 50kg, 22# early-strength stabilizer 2kg; the addition amounts of the water, modifier and 15#P.O425 cement in terms of weight fractions are: water 490kg, modifier 200kg, 15#P.O425 Cement 750kg.

[0060] 2. Make the width and thickness conform to t...

Embodiment 3

[0068] 1. Put the water and modifier into the mixing tank according to the proportion and stir for 10 minutes, then put the fireproof material 15#P.O425 cement into the mixing tank and stir for 5-10 minutes according to the proportion to obtain the cement-based inorganic slurry material;

[0069] The modifier adopts the following raw material formula: in parts by weight, it contains 65kg of 8# skeleton proppant, 130kg of 14# linking agent, 4kg of 16# suspension modifier, 7# low-end thermal conductivity reducing material 750kg, 20# Enhanced internal health agent 50kg, 22# early strength stabilizer 1kg; the addition amounts of the water, modifier and 15#P.O425 cement in terms of weight fractions are: water 410kg, modifier 100kg, 15#P. O425 cement 800kg.

[0070] 2. Make the width and thickness conform to the product specification (1200×600mm) of 7kg / m 3 The seven mature polystyrene sheet blanks are input into the high-pressure adsorption line, and the inorganic composite polys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com