Sonic soot blower as well as manufacture method and application method thereof

A technology of acoustic wave cleaning and sound wave generator is applied in the field of dust cleaning equipment in confined spaces, which can solve the problems of low dust cleaning energy, poor safety, and many dead ends of soot blowing, so as to increase the service life, protect the normal use, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

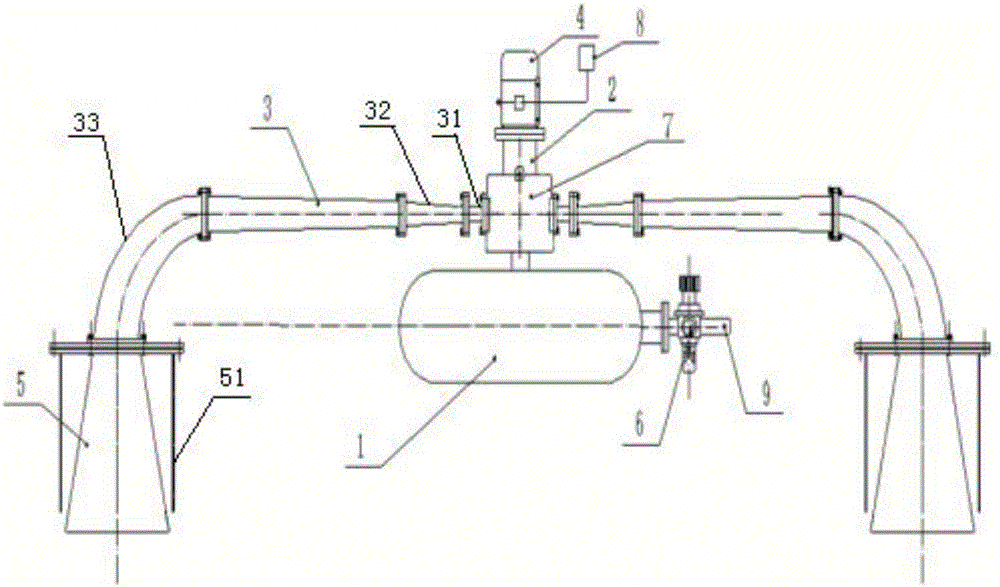

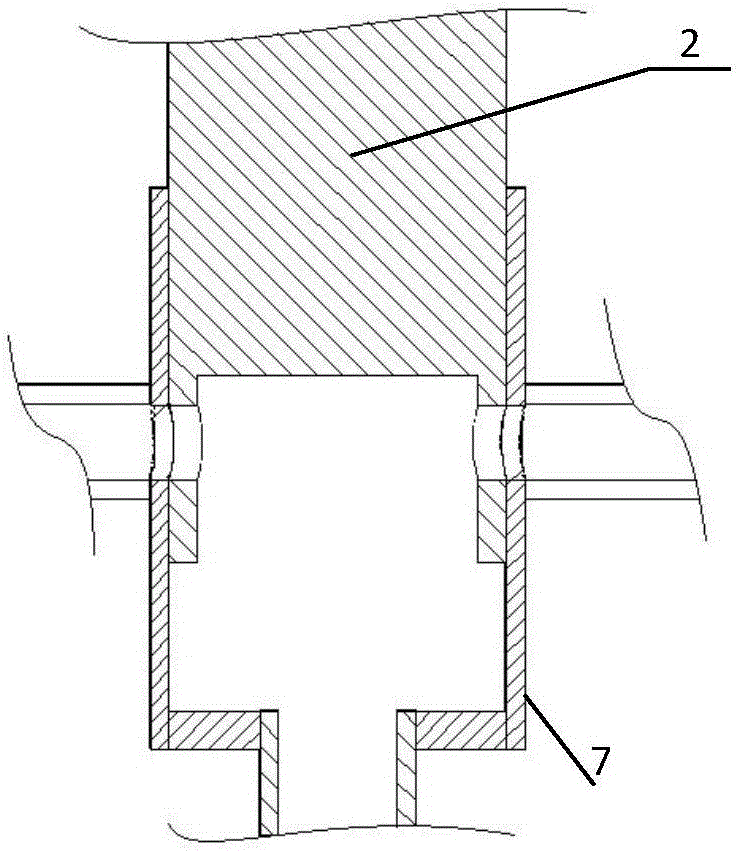

[0025] Embodiment 1: With reference to accompanying drawing, a kind of sonic cleaner, comprises sonic generator and sonic sounder, and sonic sounder comprises air inlet 9, air storage tank 1, outer cylinder 7 and motor 4, and sonic sounder Including a connection port 31, a tapered waveguide 32, a rotary conduit 3, a 90-degree waveguide 33 and a sound wave loudspeaker 5, the air inlet 9 is connected to the air storage tank 1 through an air delivery tube, and the air storage tank 1 The air outlet is connected to one end of the outer cylinder 7, the rotating shaft 2 of the motor 4 is placed inside the outer cylinder 7 and tightly connected with it, the front end part of the rotating shaft 2 is a hollow ring and at least one through hole is arranged on the ring wall , and the through hole is provided with a corresponding cylinder wall through hole corresponding to the cylinder wall of the outer cylinder 7, and the outside of the cylinder wall through hole is provided with a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com