Rotary hearth furnace smoke comprehensive treatment system and method

A comprehensive treatment, rotary hearth furnace technology, applied in combustion methods, steam generation methods using heat carriers, furnaces, etc., can solve the problems of substandard flue gas emissions, scaling and blockage of the flue gas heat exchange system of rotary hearth furnaces , to achieve the effect of solving the cost of use, good industrialization prospects, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

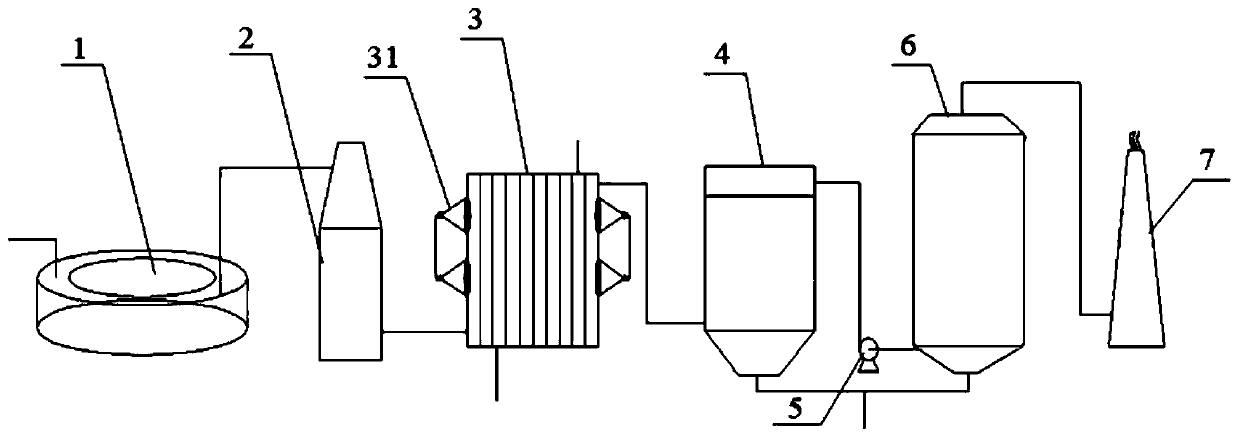

[0034] Such as figure 1 As shown, this embodiment provides a comprehensive treatment system for flue gas of a rotary hearth furnace, which includes a rotary hearth furnace 1, a high-temperature flue gas outlet of the rotary hearth furnace 1 is connected to a waste heat boiler 2, and the outlet of the waste heat boiler 2 is connected to an air heat exchanger 3. The air heat exchanger 3 is connected to the bag filter 4, the outlet end of the bag filter 4 is connected to the cyclone dust collector 6 through a pipe, a fan 5 is arranged on the pipe, and the cyclone dust collector 6 is connected to the chimney 7. In this embodiment, the high-temperature flue gas from the rotary hearth furnace 1 enters the waste heat boiler 2 for heat exchange and cooling. The flue gas from the waste heat boiler 2 is further connected to the air heat exchanger 3 for heat exchange. 3. Install the adjustable frequency high sound intensity sonic soot blower 31, the sound wave output port of the adjustable...

Embodiment 2

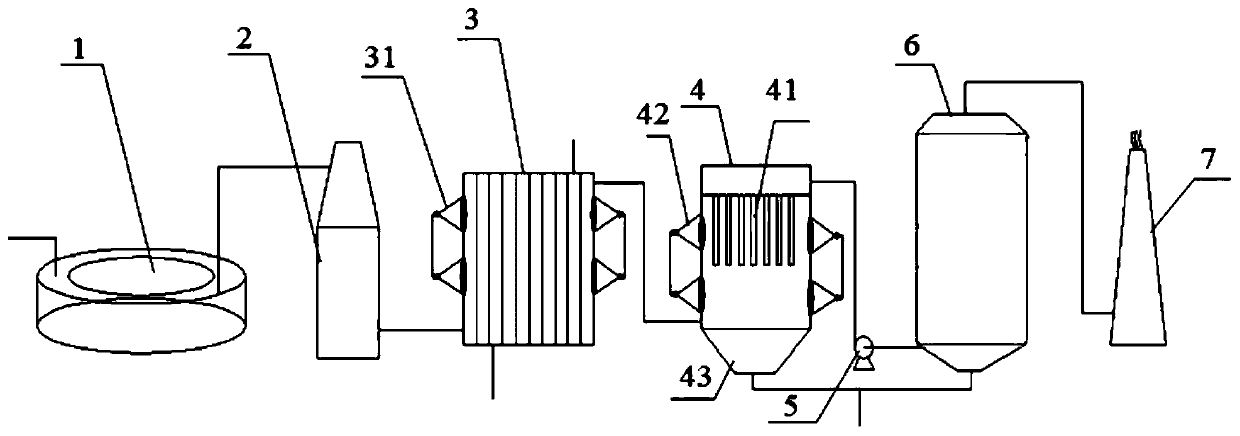

[0037] This embodiment is a further improvement on the basis of the above embodiment 1, such as figure 2 As shown, the bag filter 4 includes a dust collector body, a dust filter bag 41 arranged inside the dust collector body, and a collecting bucket 43 arranged at the bottom of the dust collector body. The inlet of the bag filter 4 is arranged at the lower part of the dust collector body. Below the dust filter bag 41, the outlet of the bag filter 4 is arranged above the dust filter bag 41 on the upper part of the dust collector body. The dust collector body is provided with a first sonic wave agglomeration device 42. The output end faces the inside of the dust collector. By installing the first acoustic wave agglomeration device 42 on the bag filter 4, the dust particles in the ultrafine dust flue gas can be agglomerated and enlarged by sound waves, and then better filtered by the dust filter bag 41, which effectively improves Dust removal efficiency and dust removal effect.

Embodiment 3

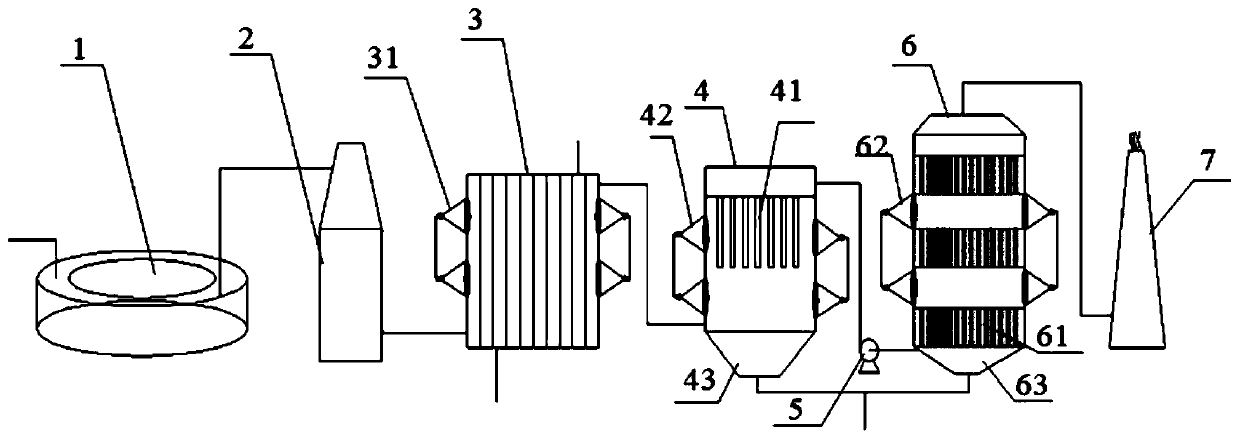

[0039] This embodiment is a further improvement on the basis of embodiment 2, such as image 3 As shown, the cyclone dust collector 6 includes a multi-stage cyclone dust removal unit 61, a transition cavity is provided between adjacent cyclone dust removal units, and a second acoustic wave agglomeration device 62 is provided on the transition cavity; the cyclone dust collector 6 is the most The inlet of the cyclone dust collector 6 is arranged below the cyclone ash removal unit at the lower end, the ash hopper 63 is arranged at the bottom end, and the outlet of the cyclone dust collector 6 is arranged at the top. Both the collection bucket (43) and the ash bucket (63) are installed in a detachable manner, which is convenient for replacement and cleaning at any time.

[0040] The rotary hearth furnace flue gas comprehensive treatment system provided in this embodiment is used to process the converter flue gas. The ultrafine dust flue gas removed by the bag filter 4 enters the cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com