Compound soot blower system for low-temperature flue gas waste heat recovery system

A technology of waste heat recovery system and low-temperature flue gas, which is applied in the field of composite sootblower system and composite sootblower system, which can solve the problems of ineffective effect, large wall area ash, and affecting the normal operation of the boiler system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

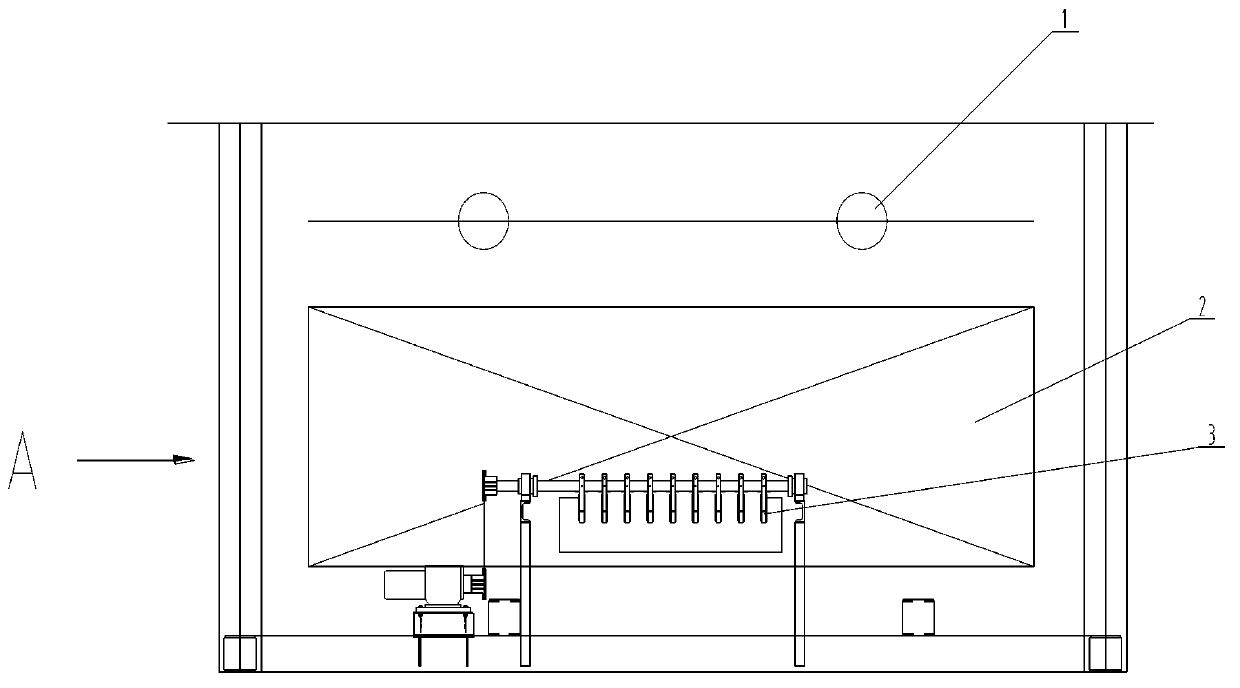

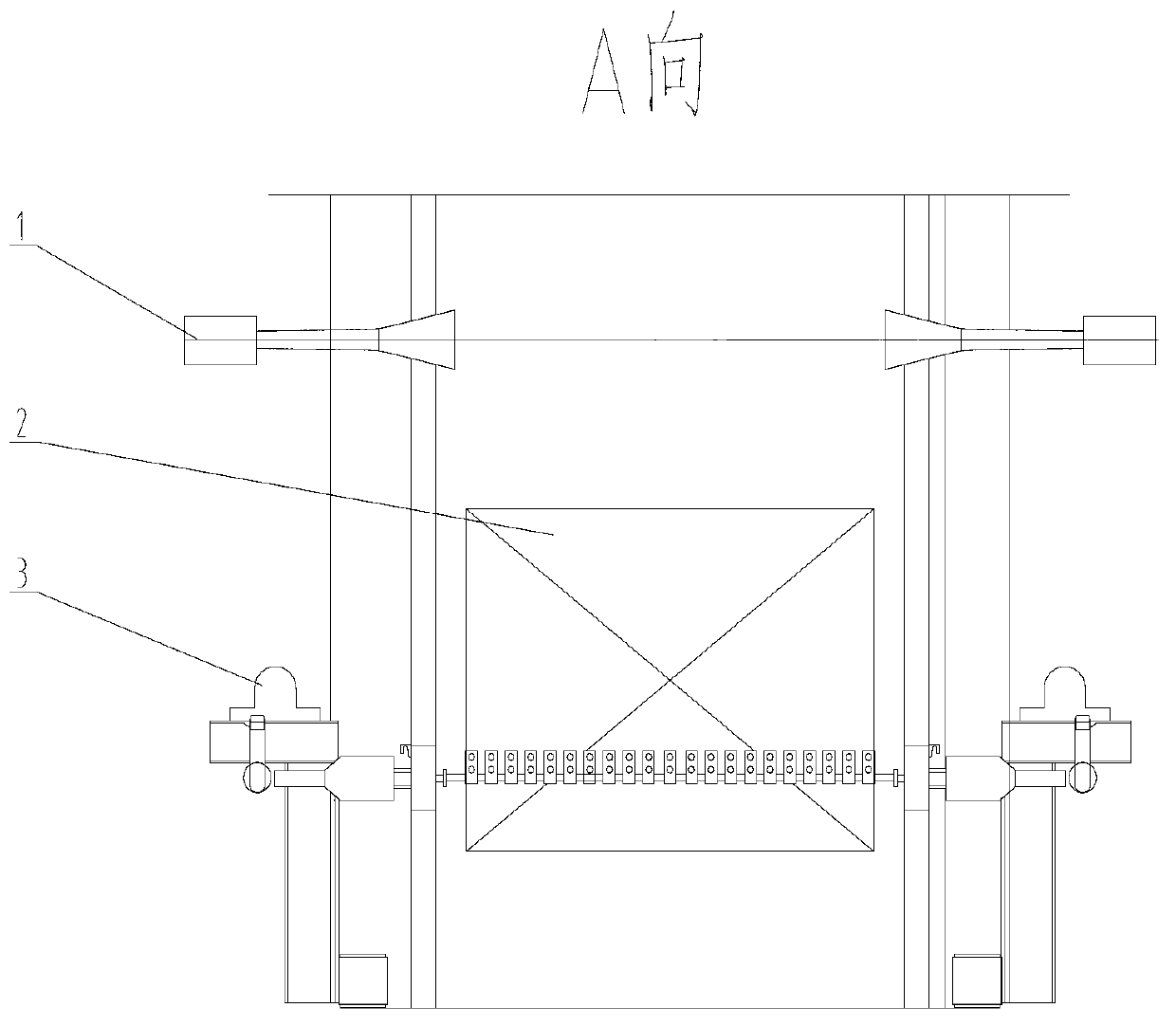

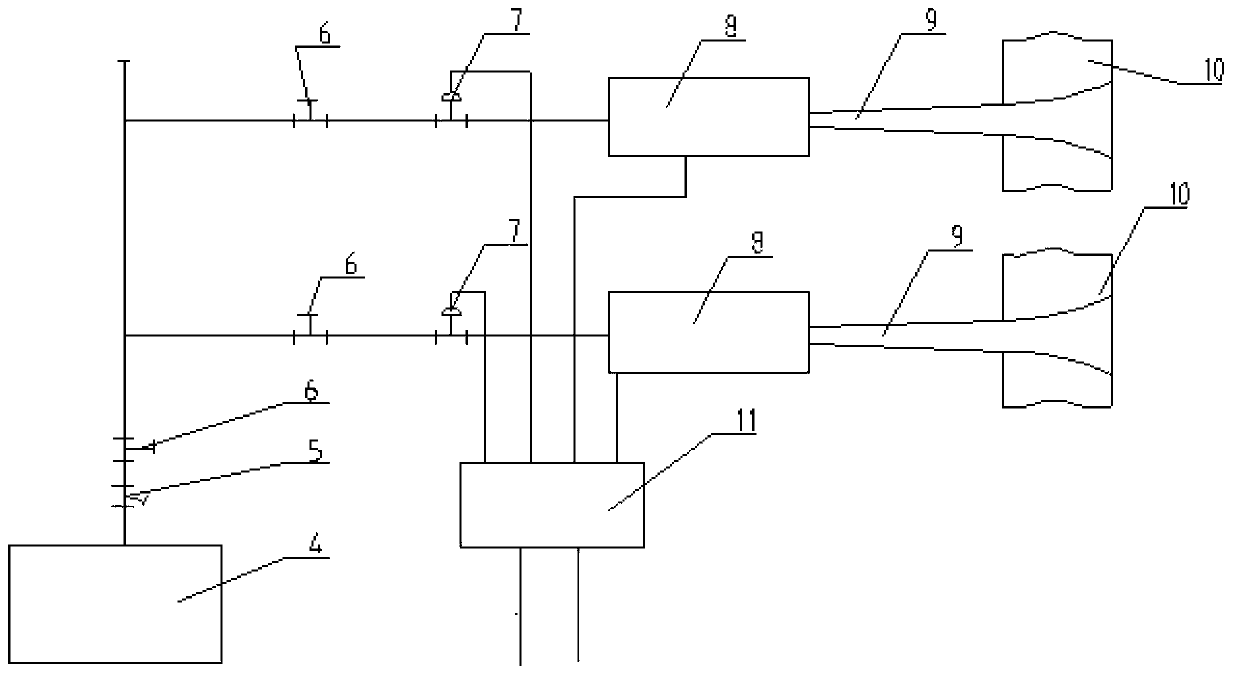

[0024] A composite sootblower system used in a low-temperature flue gas waste heat recovery system, including a flue gas waste heat recovery device 2, an acoustic wave soot blowing system 1 is provided at the entrance of the flue gas waste heat recovery device 2, and a flue gas waste heat recovery device The exit of 2 is equipped with mechanical vibration cleaning system 3.

[0025] The sonic soot blowing system adopts intermittent soot blowing, which has the characteristics of high strength and wide coverage. It can blow off the smoke and dust in the inlet pipe row of the waste heat recovery device and the sound wave coverage area; the mechanical vibration cleaning system is arranged at the outlet of the waste heat recovery device. The rapping device gives mechanical vibration to the tube row on the heating surface, so as to achieve the purpose of cleaning the dust ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com