High energy environment-friendly sonic soot blower

A sonic sootblower and environment-friendly technology, which is applied in the field of high-energy and environment-friendly sonic sootblowers, can solve the problems of large noise outside the furnace, affecting the physical and mental health of workers, noise pollution, etc., so as to improve the working environment, reduce noise, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

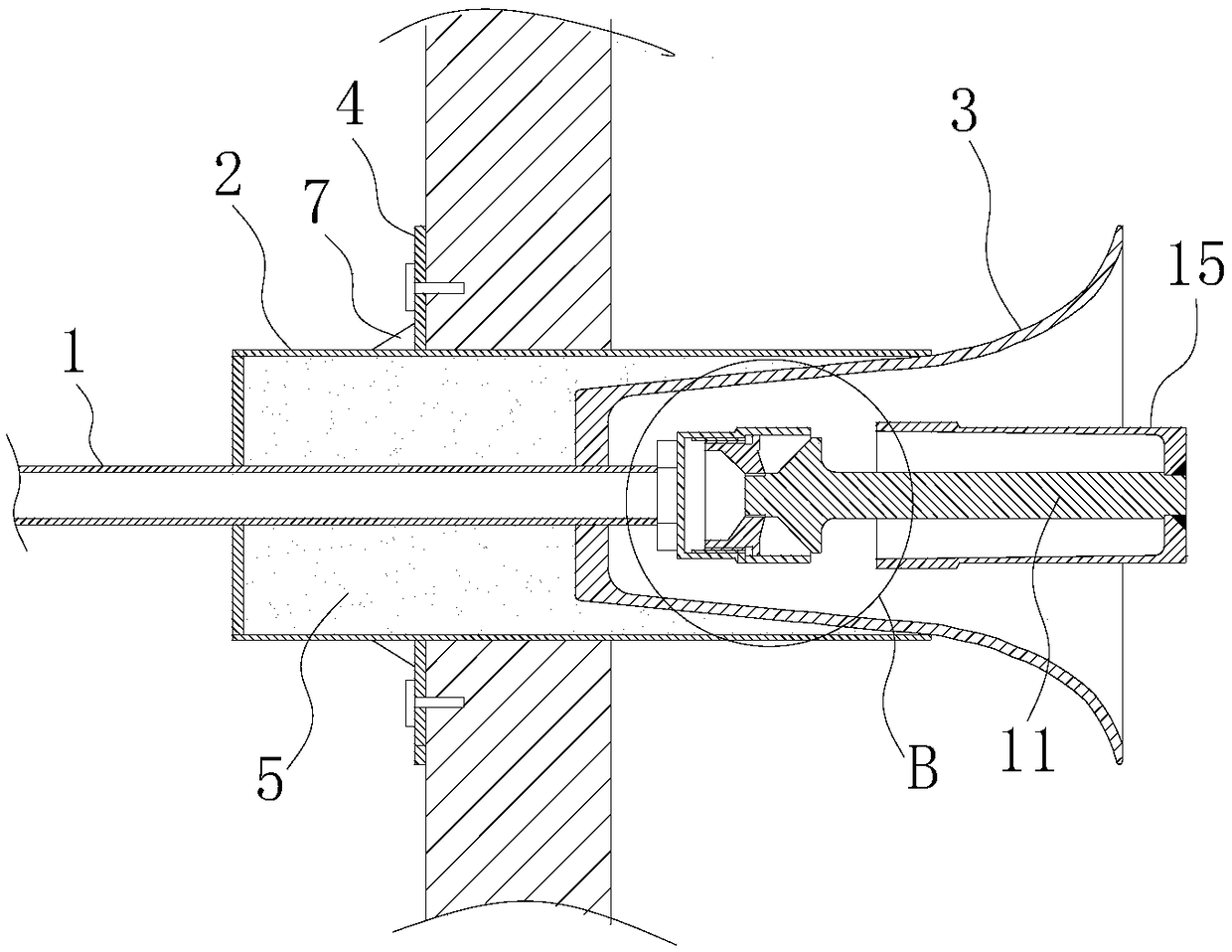

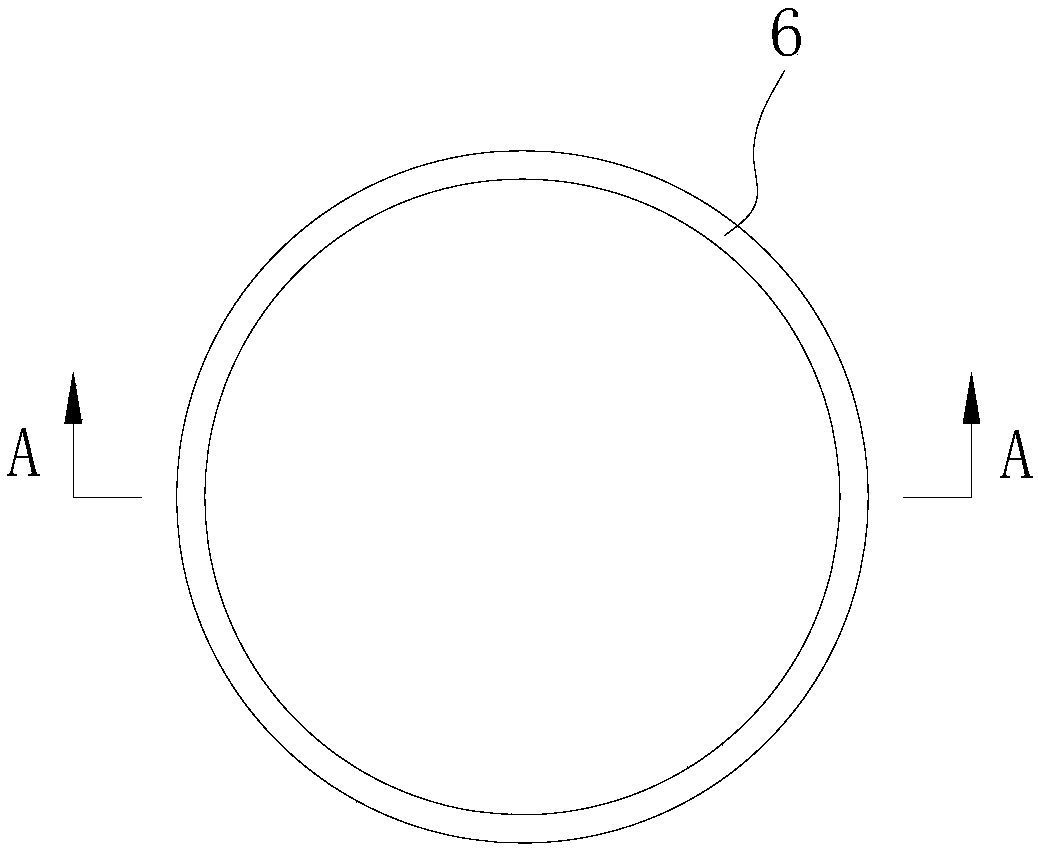

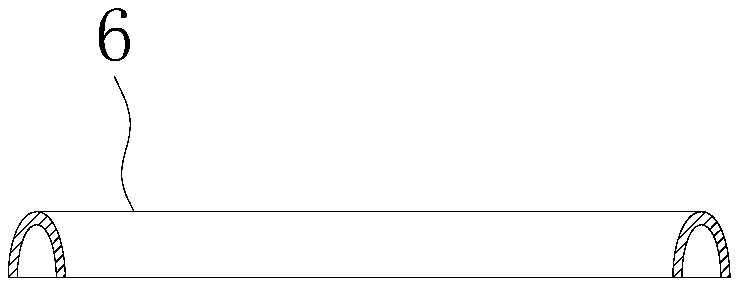

[0019] Such as Figure 1-5 A high-energy environment-friendly sonic soot blower is shown, which includes a main body of the soot blower, an air inlet pipe 1 and a cylindrical installation sleeve 2 with one end open and the other closed. The main body of the sootblower includes a heat-resistant steel horn 3 and a sound-generating component arranged in the heat-resistant steel horn 3. The sound-generating component can be a conventional commercially available sound-generating component, which is the prior art.

[0020] Of course, in order to increase the sound wave energy of the present invention, it is better that the sound generating assembly includes an air flow cover 8 with one end connected to the air intake pipe 1 and the other end open, and a distribution plate 9 is arranged inside the air flow cover 8 . The outer peripheral surface of the distribution plate 9 is provided with threads and is threadedly connected with the airflow cover 8, which can ensure the convenience o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com