Trumpet for acoustic wave sootblower

A sonic sootblower and horn technology, which is applied in the horn field to achieve the effects of good practicability, simple structure and avoiding sudden change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

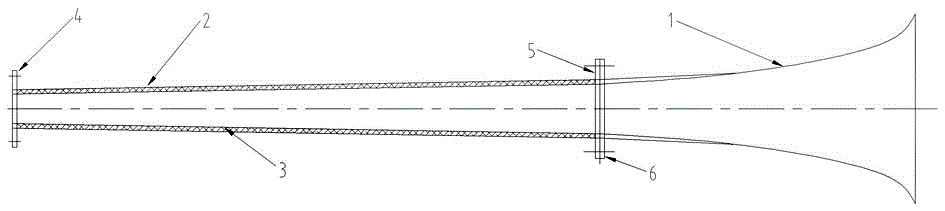

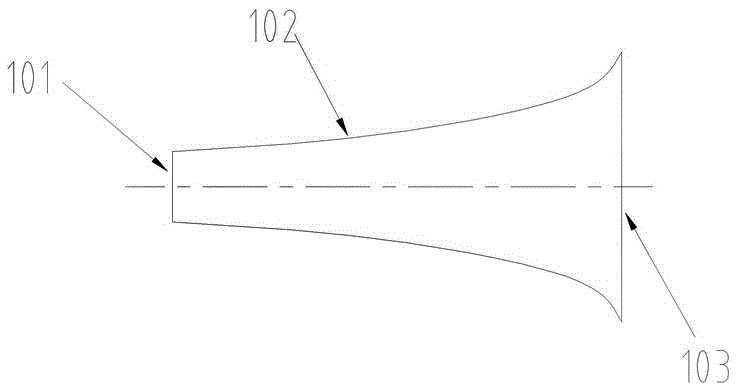

[0022] combined with figure 1 And attached figure 2 , a horn for a sonic soot blower, which includes a horn mouth 1, the horn mouth 1 includes two parts, a large end and a small end, and the small end of the horn mouth 1 is composed of a horn outer shell 2 and a horn inner shell 3 , there is a gap of 10 mm between the inner horn shell 2 and the horn outer shell 3, the gap is filled with river sand as a damping and sound-insulating material, and a small end inlet flange 4 is installed at the entrance of the small end of the horn mouth 1, A small end outlet flange 5 is installed at the small end outlet of the bell mouth 1; a large end inlet flange 6 is installed at the big end inlet 101 of the bell mouth 1, and the big end and the small end of the bell mouth 1 pass through the small end outlet The flange 5 is connected with the large-end inlet flange 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com