Coating for frequency-adjustable high-sound-intensity soot blower sound production assembly, and preparation method for coating

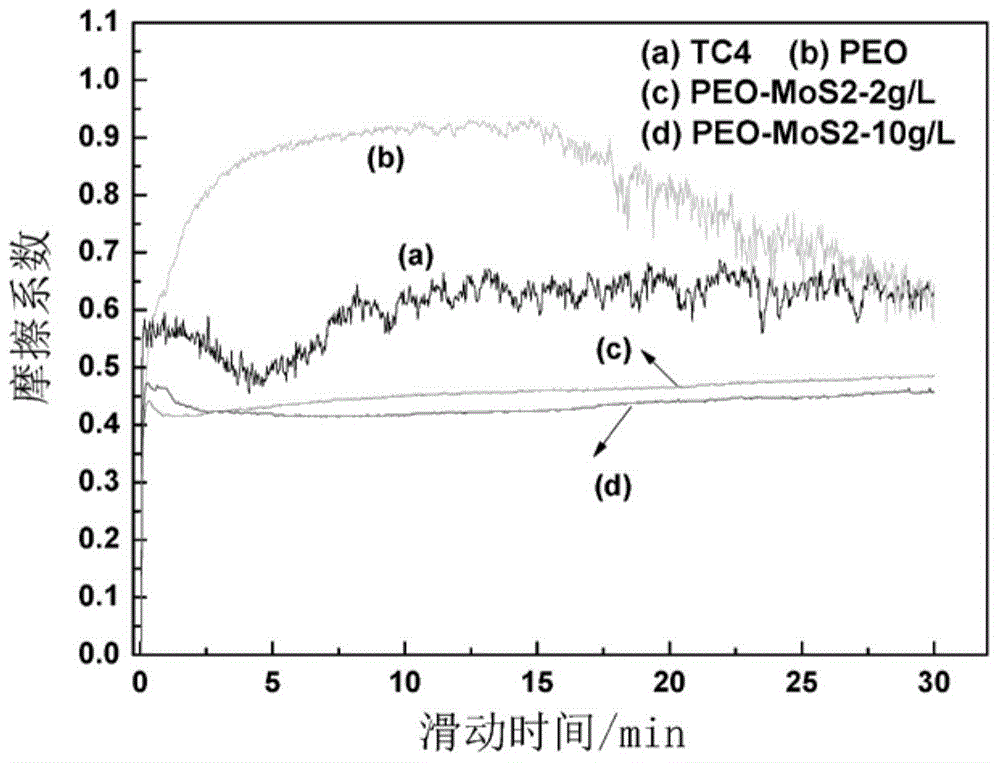

A technology of soot blower and strong sound wave, which is applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc. It can solve the problems of affecting the matching accuracy of sounding components, the influence of sounding component matching accuracy, and deformation of sounding components, so as to avoid sounding Component mismatch, reduce repeated tooling, and reduce the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

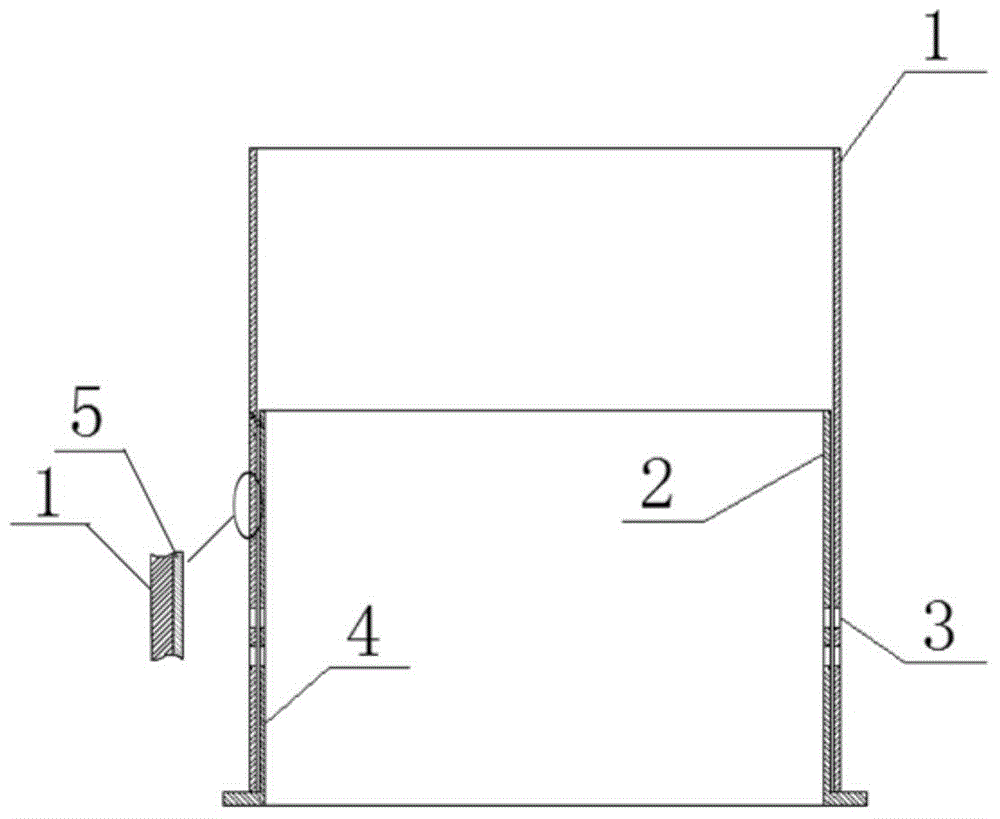

[0032] (1) Using HF-HNO 3 The solution activates the outer cylindrical thin-walled part 1 of the sound generating component;

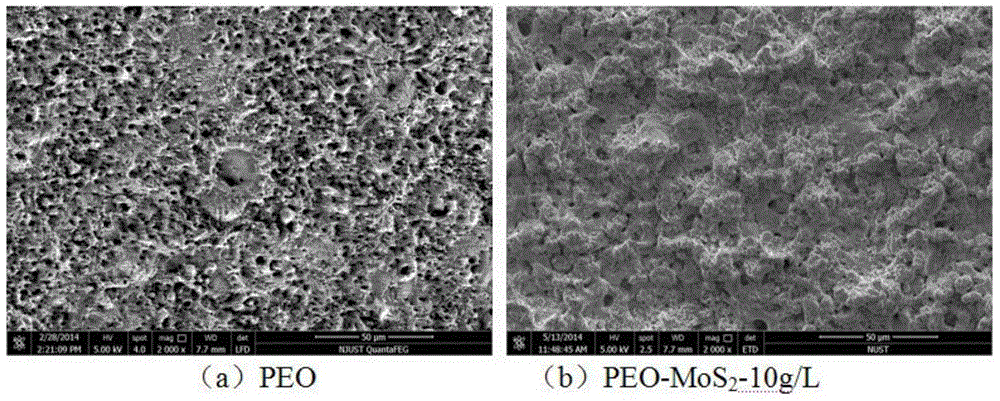

[0033] (2) Measure 1000mL of deionized water, divide it into two parts, weigh 1g of sodium silicate, 5g of sodium phosphate and 0.3g of sodium hydroxide, and add them to 500mL of deionized water to dissolve in turn to make solution A, and weigh another ten Sodium Dialkylbenzene Sulfonate 0.015g, Nano MoS 2 Add 2g of particles and 100mL of absolute ethanol to 500mL of deionized water in turn to make solution B, then mix solution A and solution B evenly, pH=12, use magnetic stirring and ultrasonic dispersion for 30 minutes each;

[0034] (3) Partially immerse the outer cylindrical thin-walled part 1 into the suspension, keeping its axial direction parallel to the liquid surface;

[0035] (4) The outer cylindrical thin-walled part 1 is the anode, and is driven by the motor to rotate axially at a constant speed at a speed of 1r / min. It is subjected to pl...

Embodiment 2

[0037] (1) Using HF-HNO 3 The solution activates the outer cylindrical thin-walled part 1 of the sound generating component;

[0038] (2) Measure 1000mL of deionized water, divide it into two parts, weigh 2g of sodium silicate, 2g of sodium phosphate and 1g of sodium hydroxide, and add them to 500mL of deionized water to dissolve in order to make solution A, and weigh another twelve Sodium Alkylbenzene Sulfonate 0.02g, Nano MoS 2Add 10g of particles and 150mL of absolute ethanol to 500mL of deionized water in turn to make solution B, then mix solution A and solution B evenly, pH=14, use magnetic stirring and ultrasonic dispersion for 45 minutes each;

[0039] (3) Partially immerse the outer cylindrical thin-walled part 1 into the suspension, keeping its axial direction parallel to the liquid surface;

[0040] (4) The outer cylindrical thin-walled part 1 is the anode, and is driven by a motor to rotate axially at a constant speed at a speed of 3r / min. It is subjected to plasm...

Embodiment 3

[0042] (1) Using HF-HNO 3 The solution activates the outer cylindrical thin-walled part 1 of the sound generating component;

[0043] (2) Measure 1000mL of deionized water and divide it into two parts. Weigh 5g of sodium silicate, 1g of sodium phosphate and 0.6g of sodium hydroxide, and dissolve them in 500mL of deionized water to make solution A. Sodium Dialkylbenzene Sulfonate 0.025g, Nano MoS 2 Add 25g of particles and 250mL of absolute ethanol to 500mL of deionized water in turn to make solution B, then mix solution A and solution B evenly, pH=14, use magnetic stirring and ultrasonic dispersion for 60 minutes each;

[0044] (3) Partially immerse the outer cylindrical thin-walled part 1 into the suspension, keeping its axial direction parallel to the liquid surface;

[0045] (4) The outer cylindrical thin-walled part 1 is the anode, and is driven by a motor to rotate axially at a constant speed at a speed of 5 r / min. It is subjected to plasma electrolytic oxidation treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com