Flue gas desulfurization reactor for descending circulating fluidized bed

A circulating fluidized bed and reactor technology, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of uneven flow field, complex pulping system, low circulation rate, etc., and solve technical problems. , High cycle rate, the effect of reducing dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

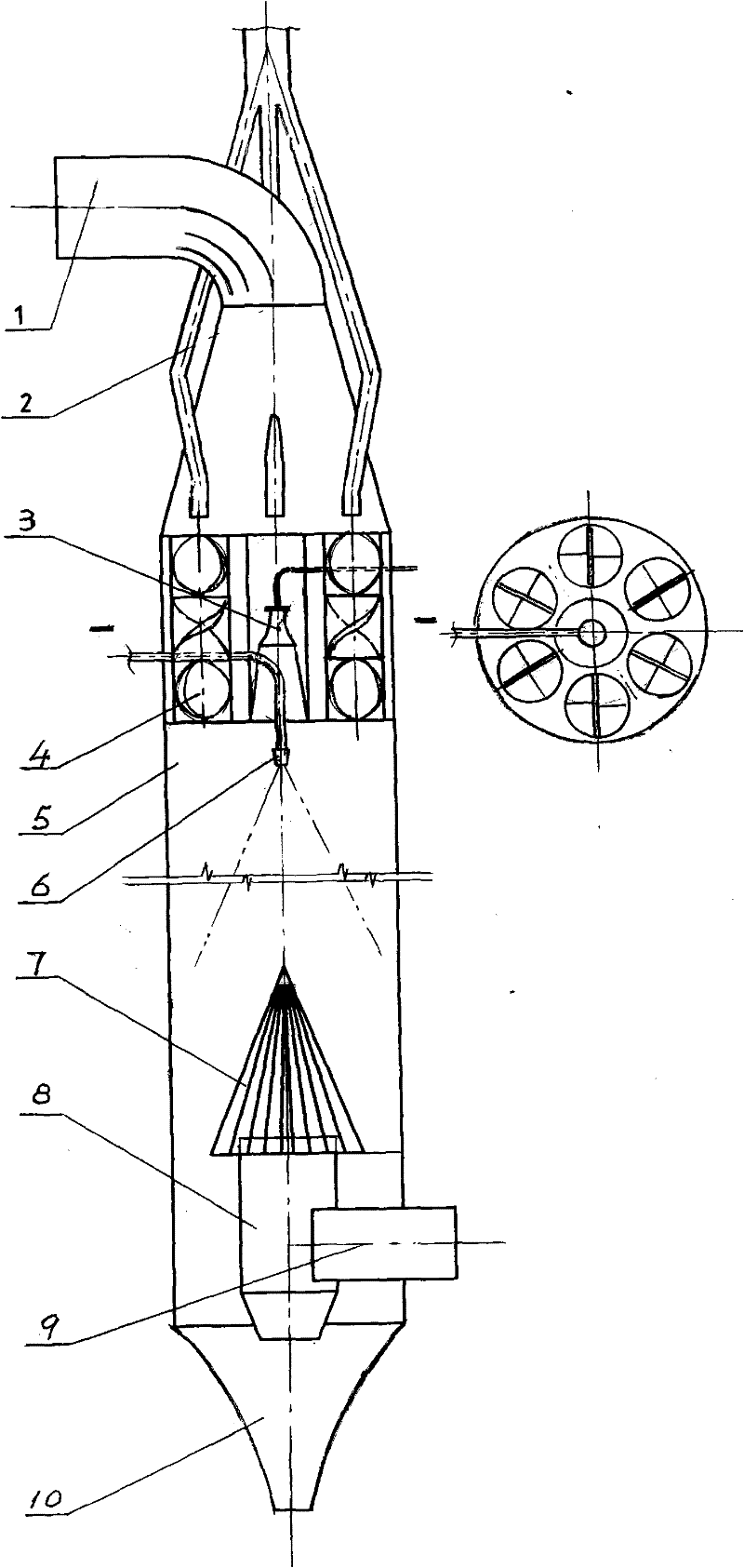

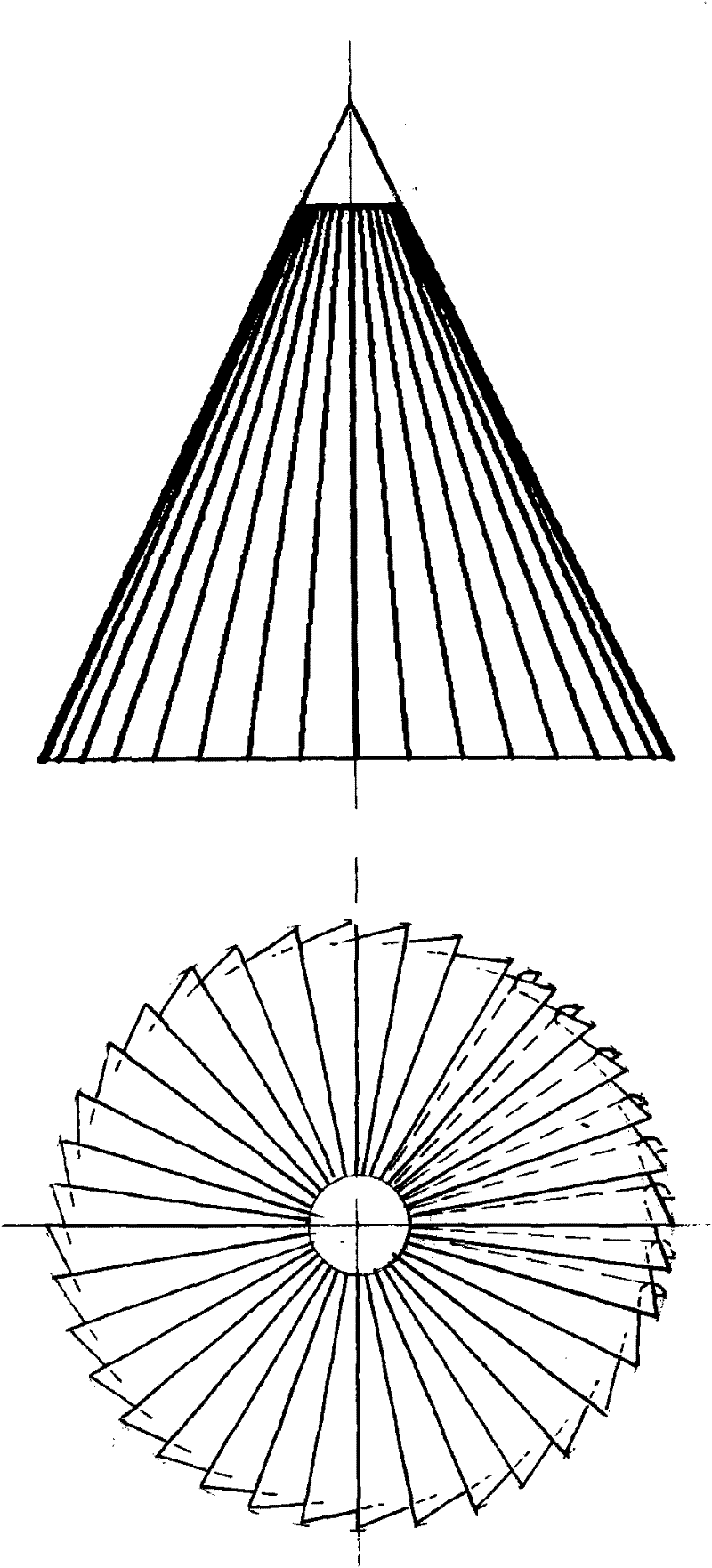

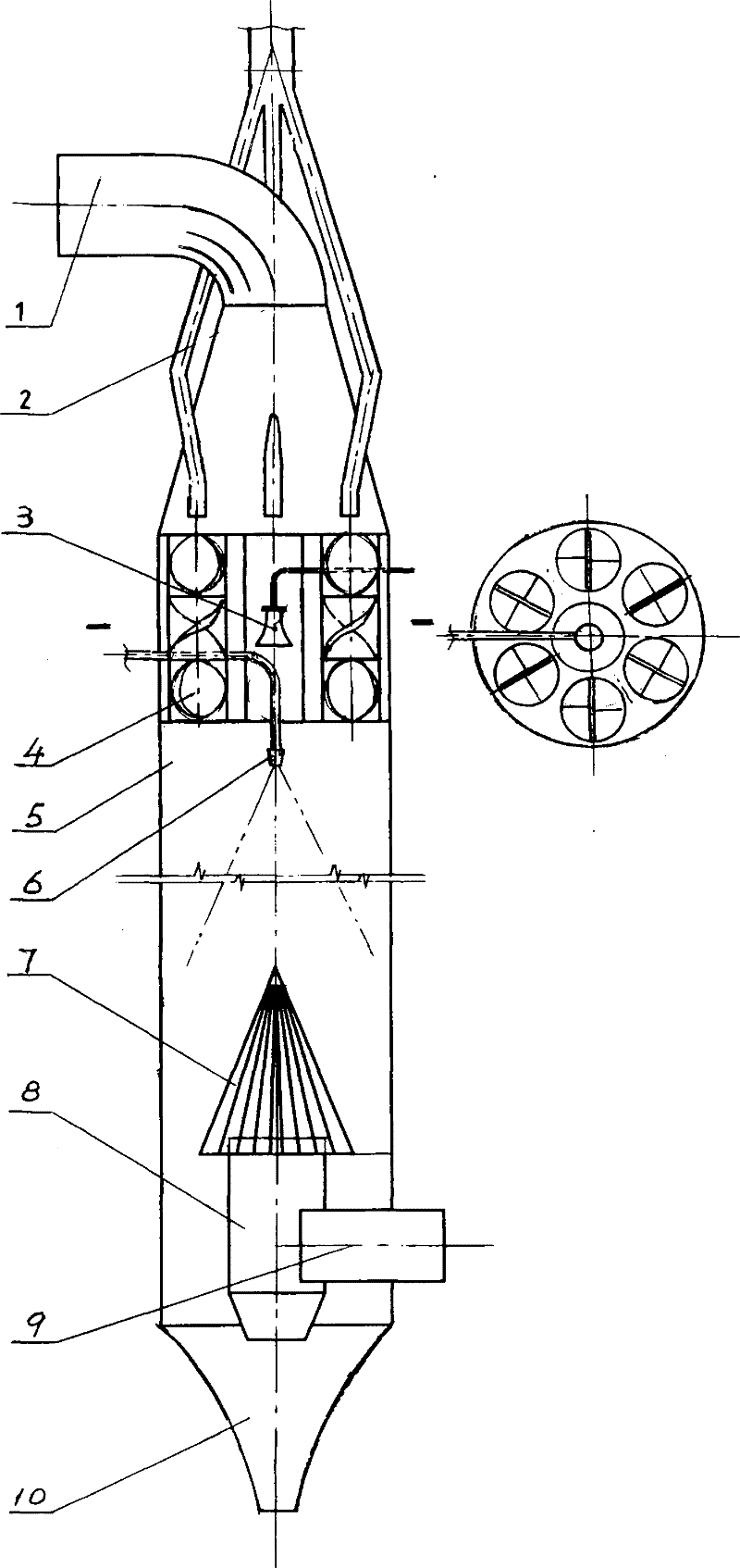

[0044] see figure 1 , the descending circulating fluidized bed flue gas desulfurization reactor, from top to bottom are: direct current streamlined inlet flue 1, absorbent uniform distributor 2, acoustic soot blower 3, static mixer 4, reactor shell 5, Humidifying and activating nozzle 6 , conical swirling plate gas-solid separator 7 , gas-solid separation guide tube 8 , desulfurization flue gas outlet flue 9 and hyperbolic ash hopper 10 .

[0045] DC streamlined inlet flue, absorbent uniform distributor, sonic soot blower, static mixer, conical swirling plate gas-solid separator, and gas-solid separation guide tube located below the gas-solid separator, and desulfurization fume The gas outlet flue and the hyperbolic ash hopper are unique structures of the present invention.

[0046] The flue gas from the sintering machine in the iron and steel industry, and the flue gas from the boilers in coal-fired power plants and waste incineration power plants enter the reactor from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com