Multifunctional acoustic wave sootblower with ample power

A sonic sootblower, a multi-functional technology, is used in the treatment of combustion products, combustion methods, and removal of solid residues, etc. The effect of operating environment, avoiding environmental noise pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

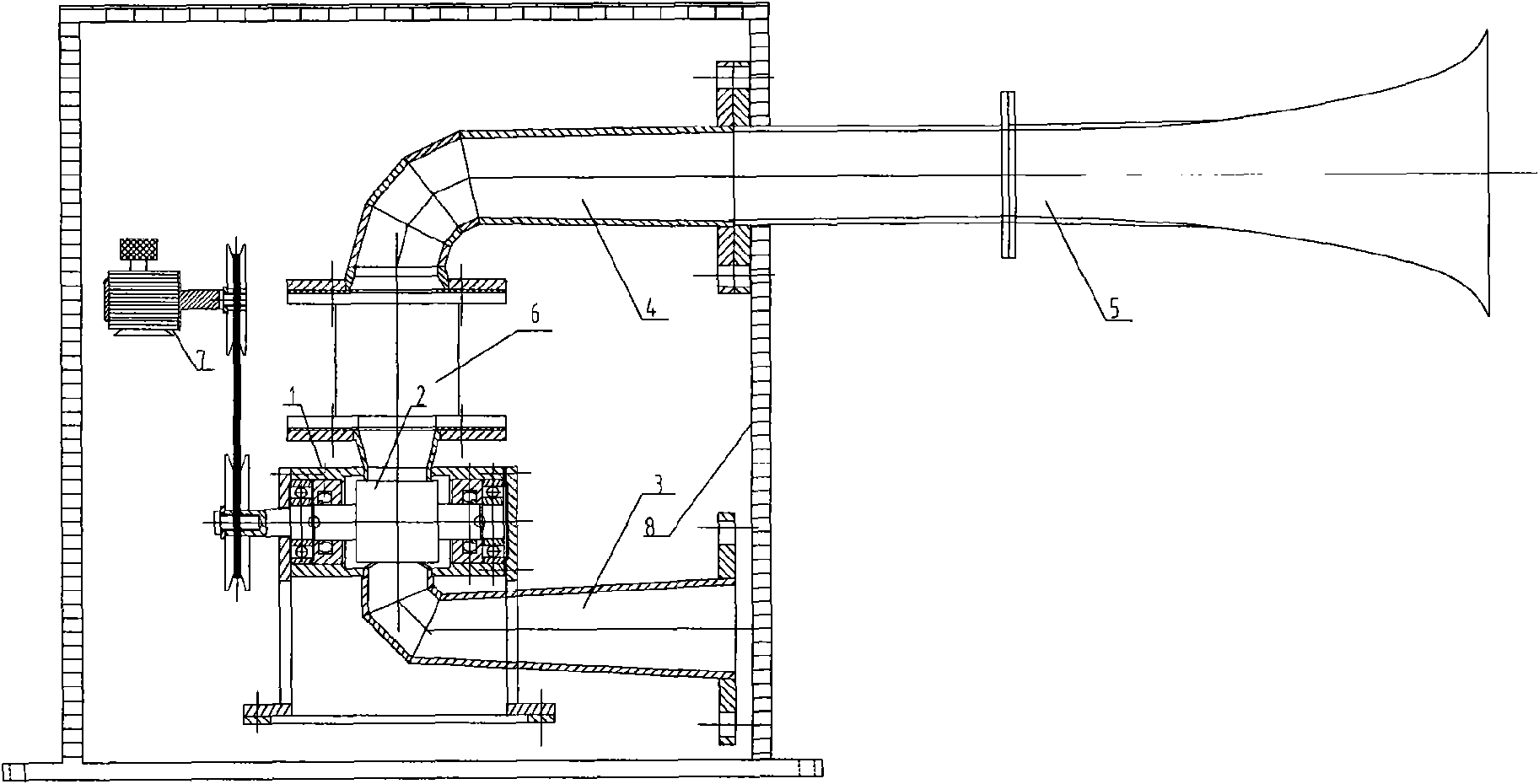

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

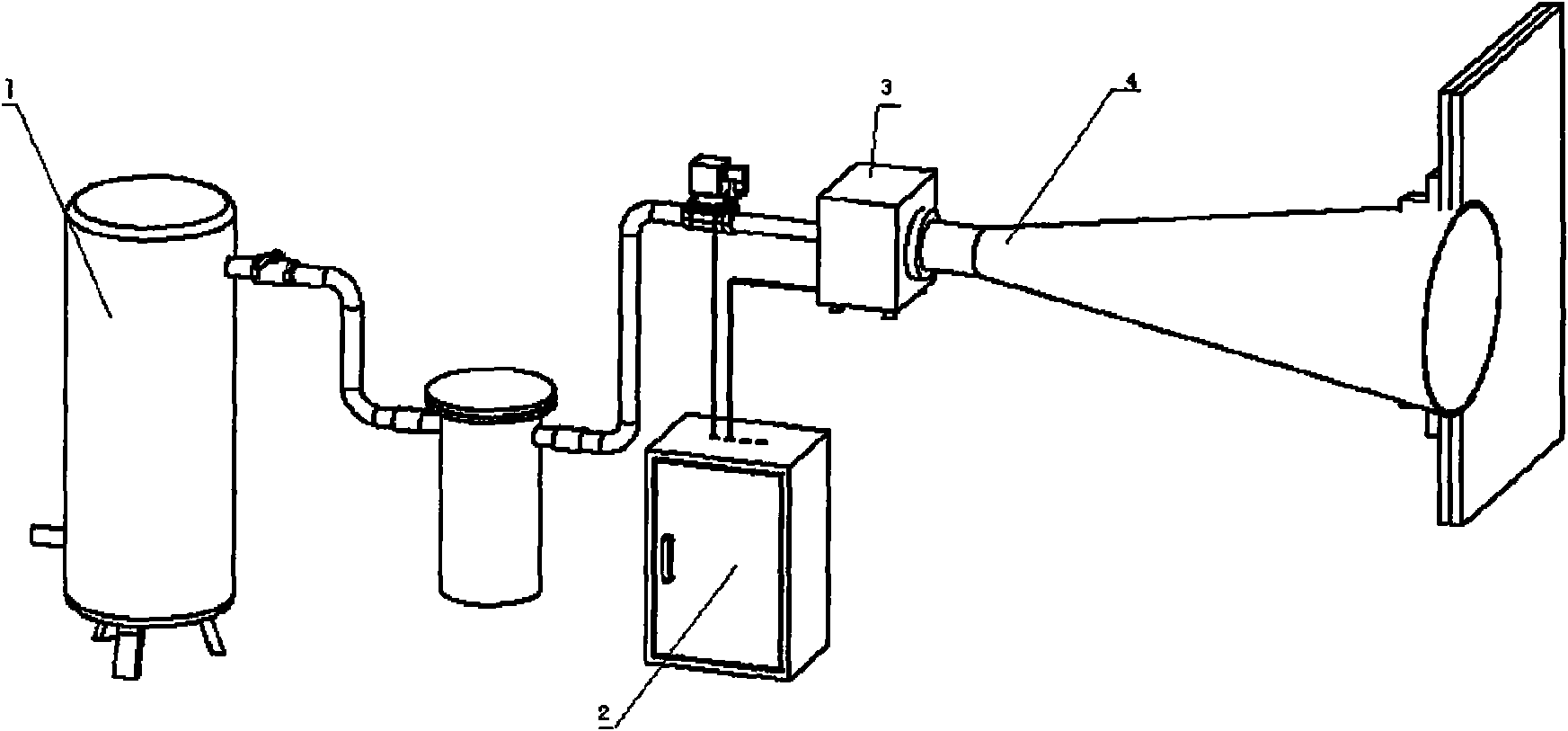

[0014] As shown in the figure, a high-power multifunctional sonic soot blower, the sonic generator is connected to the sonic transmission amplifier 5 through the air outlet pipe 4, the air source is connected to the sonic generator through the inlet pipe 3, and the sonic generator includes a stator 1 and a rotor 2. There are several holes or slots of different sizes on the rotor 2. The rotor is connected to the frequency conversion speed regulating motor 7 through a belt drive. A check valve 6 is installed between the air outlet pipe 4 and the stator 1. The sound wave generator is placed in a soundproof cabinet. Inside 8, the sound wave transmission amplifier 5 is flange-connected to the outlet end of the outlet pipe 4 outside the sound-proof case 8, the air source is flange-connected to the inlet end of the sound-wave generator inlet pipe 3 outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com