Energy-saving system with automatic ash removal function of horizontal type gas heat exchanger

An energy-saving system, ash-horizontal technology, applied in the field of automatic ash-removing horizontal gas heat exchanger energy-saving systems, can solve problems such as the inability to meet the technological requirements of enterprises, and achieve the purpose of prolonging service life, improving heat exchange efficiency, and reducing dust particles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

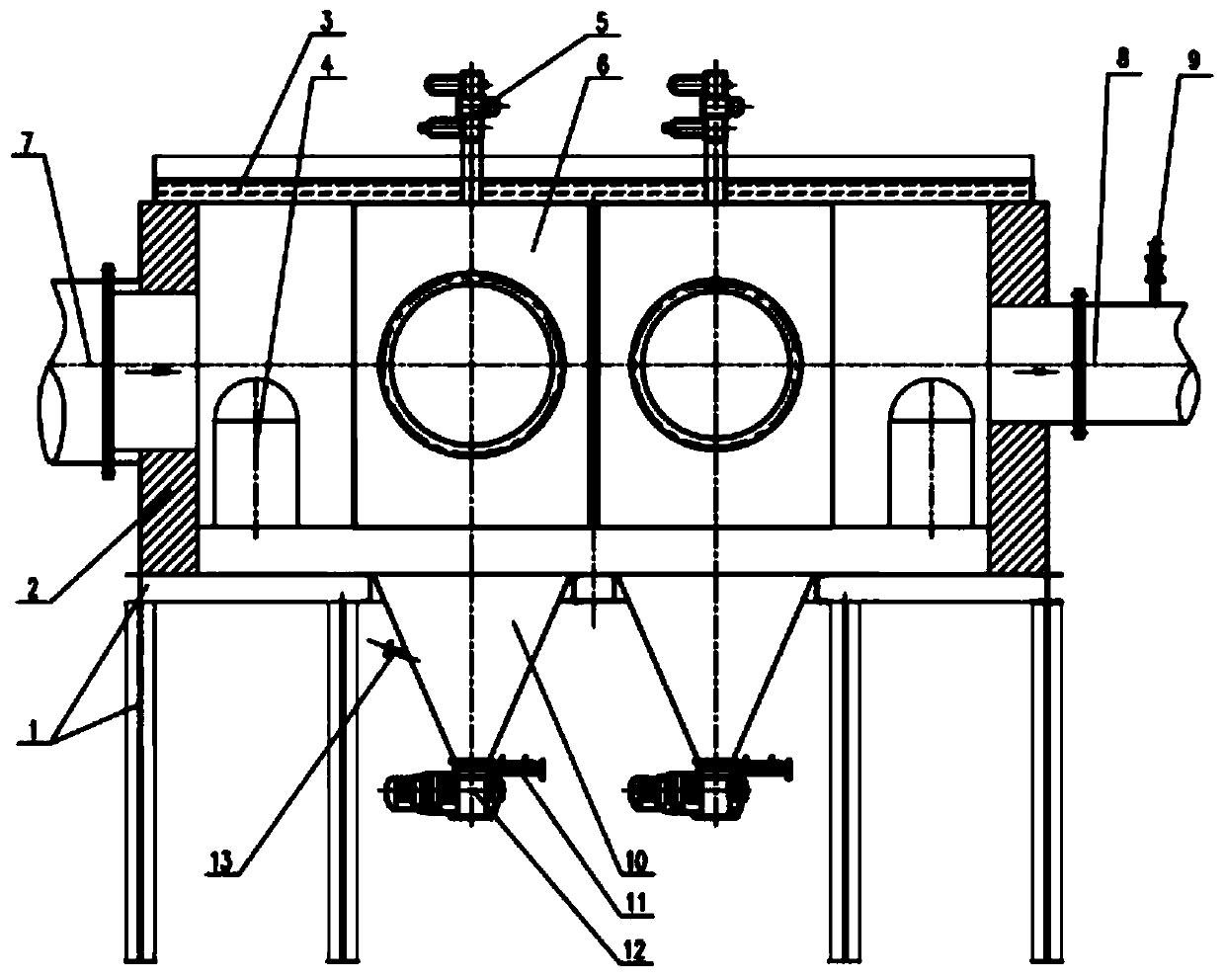

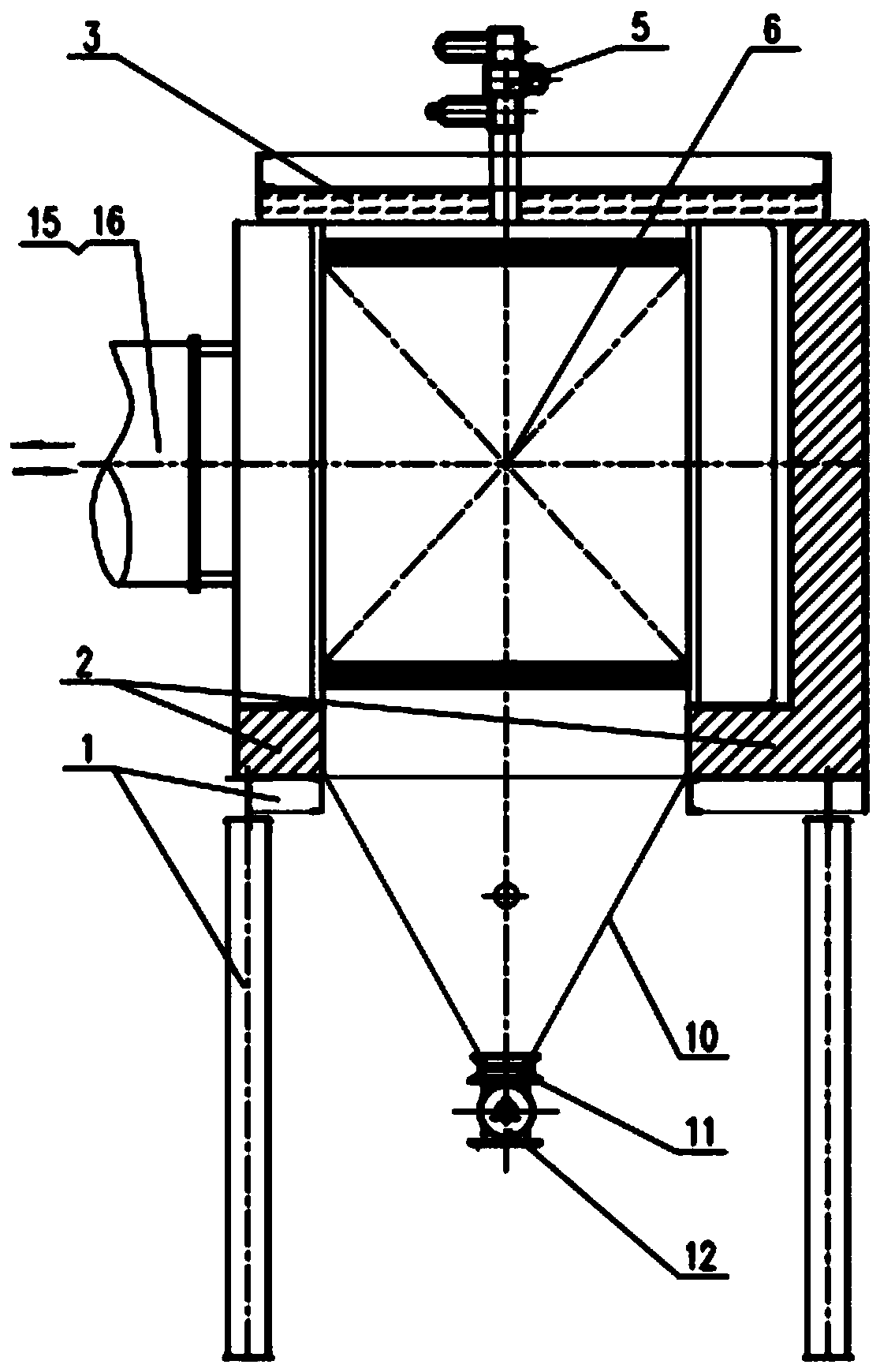

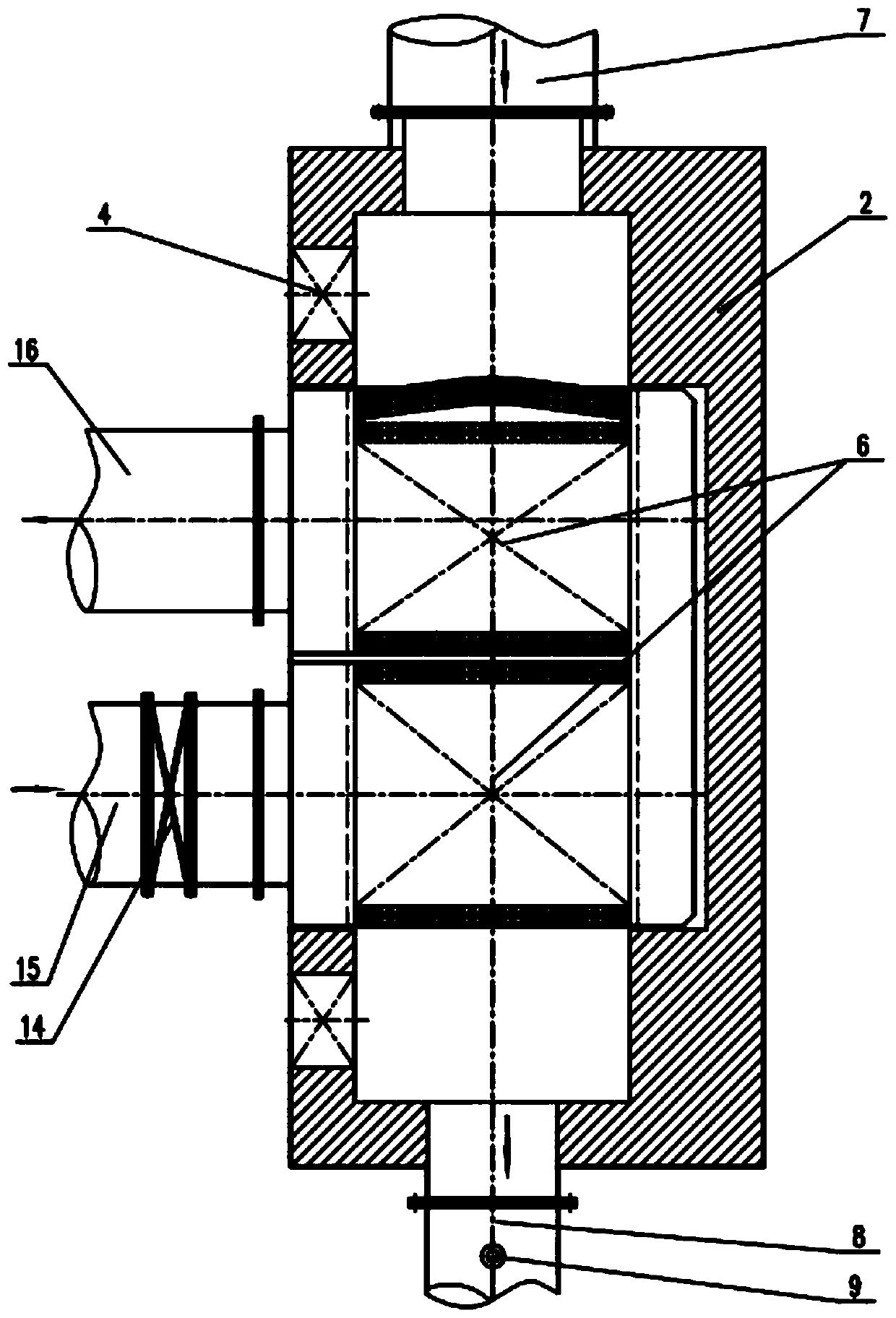

[0026] From Figure 1-3 It can be seen that the energy-saving system for an automatic ash-removing horizontal gas heat exchanger in this embodiment includes a steel structure support frame 1, and the upper part of the steel structure support frame 1 carries a horizontal energy-saving heat exchanger 6, and the horizontal energy-saving heat exchanger 6 The inner wall of the heater 6 is built with an inner masonry insulation layer 2, and the upper part of the horizontal energy-saving heat exchanger 6 is equipped with a sonic soot blower 5, and the input end of the horizontal energy-saving heat exchanger 6 is connected with a flue gas pipe 7, The output end of the horizontal energy-saving heat exchanger 6 is connected with a flue gas outlet pipe 8 , and a gas monitoring instrument 9 is installed on the pipeline of the flue gas outlet pipe 8 .

[0027] The bottom of the horizontal energy-saving heat exchanger 6 is provided with dust bins 10 at intervals, and the middle of the horiz...

Embodiment 2

[0035] On the basis of Embodiment 1, the gas monitoring instrument 9 and the gas pneumatic cut-off valve 14 are discarded, and the hot gas outlet pipeline 16 and the cold gas inlet pipeline 15 are respectively compared to the hot air outlet pipeline and the normal temperature air inlet pipeline.

[0036] It can be realized: after the hot flue gas enters the horizontal energy-saving heat exchanger 6 from the flue gas inlet pipe 7, it is discharged from the flue gas outlet pipe 8, and the air enters the horizontal energy-saving heat exchanger 6 from the normal-temperature air inlet pipe, and after heat exchange , enters the combustion system after passing through the hot air outlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com