Flue gas denitration system

A flue gas and denitration technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as increasing airflow resistance, reducing catalyst activity, explosion, etc., to prevent deformation of steel structures, ensure service life, The effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

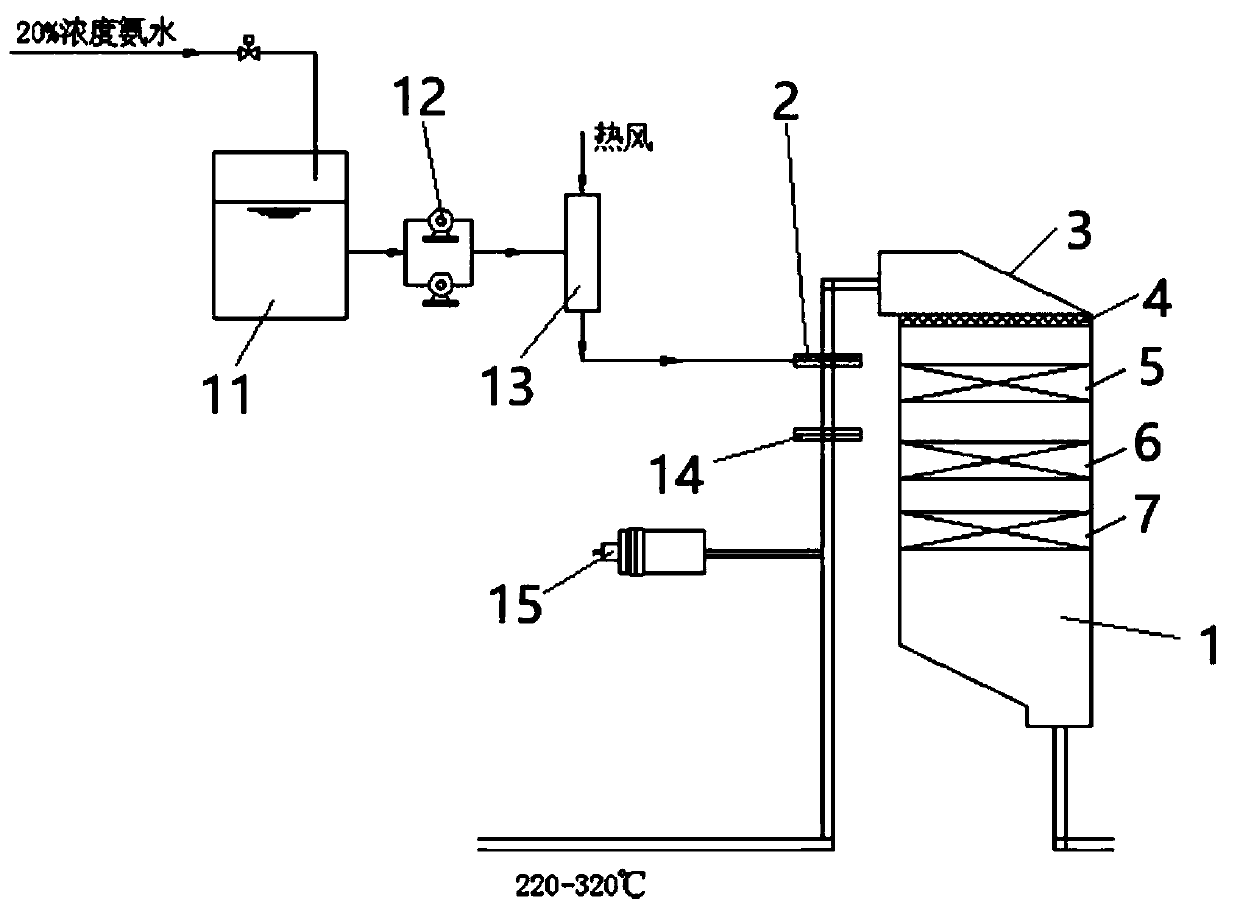

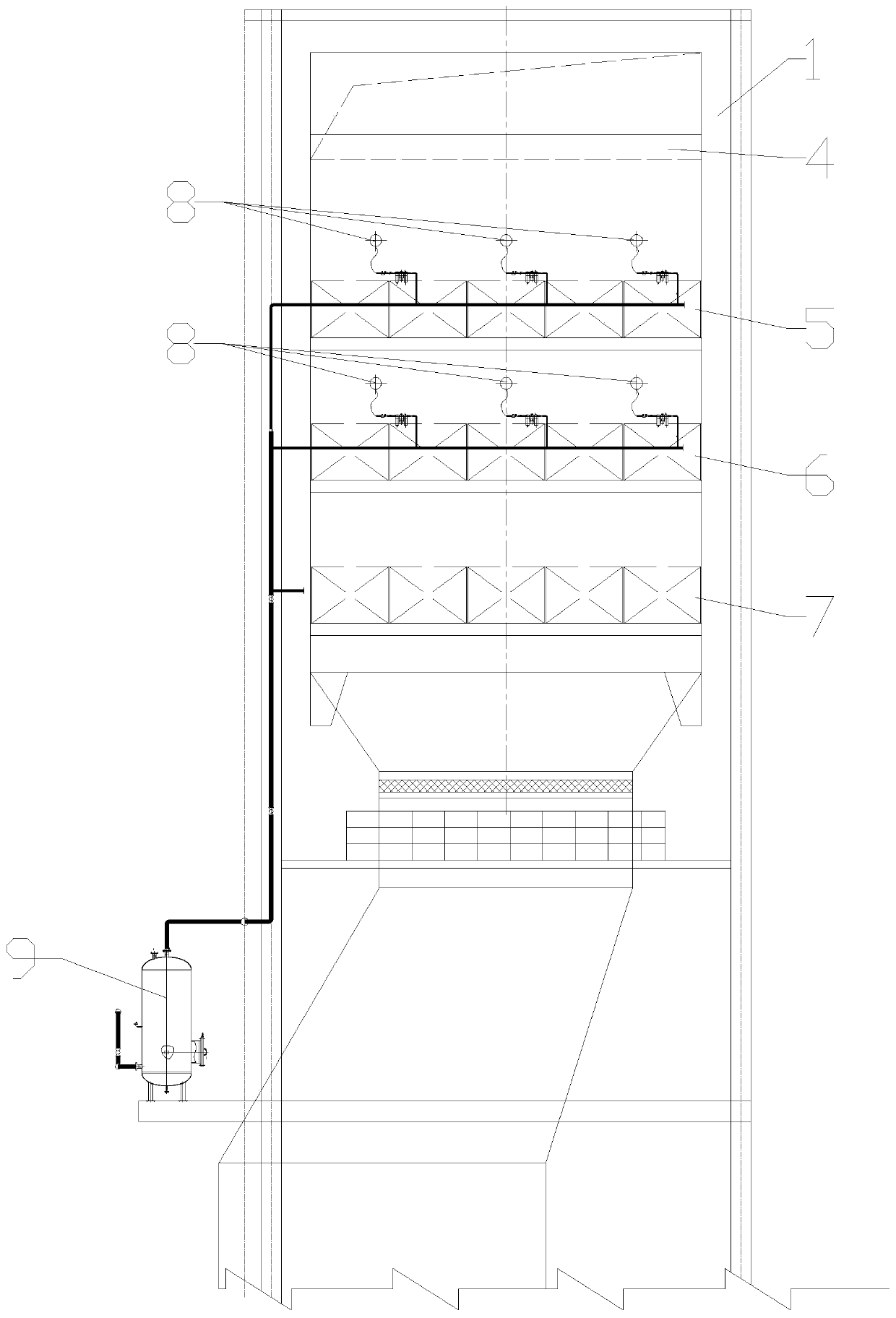

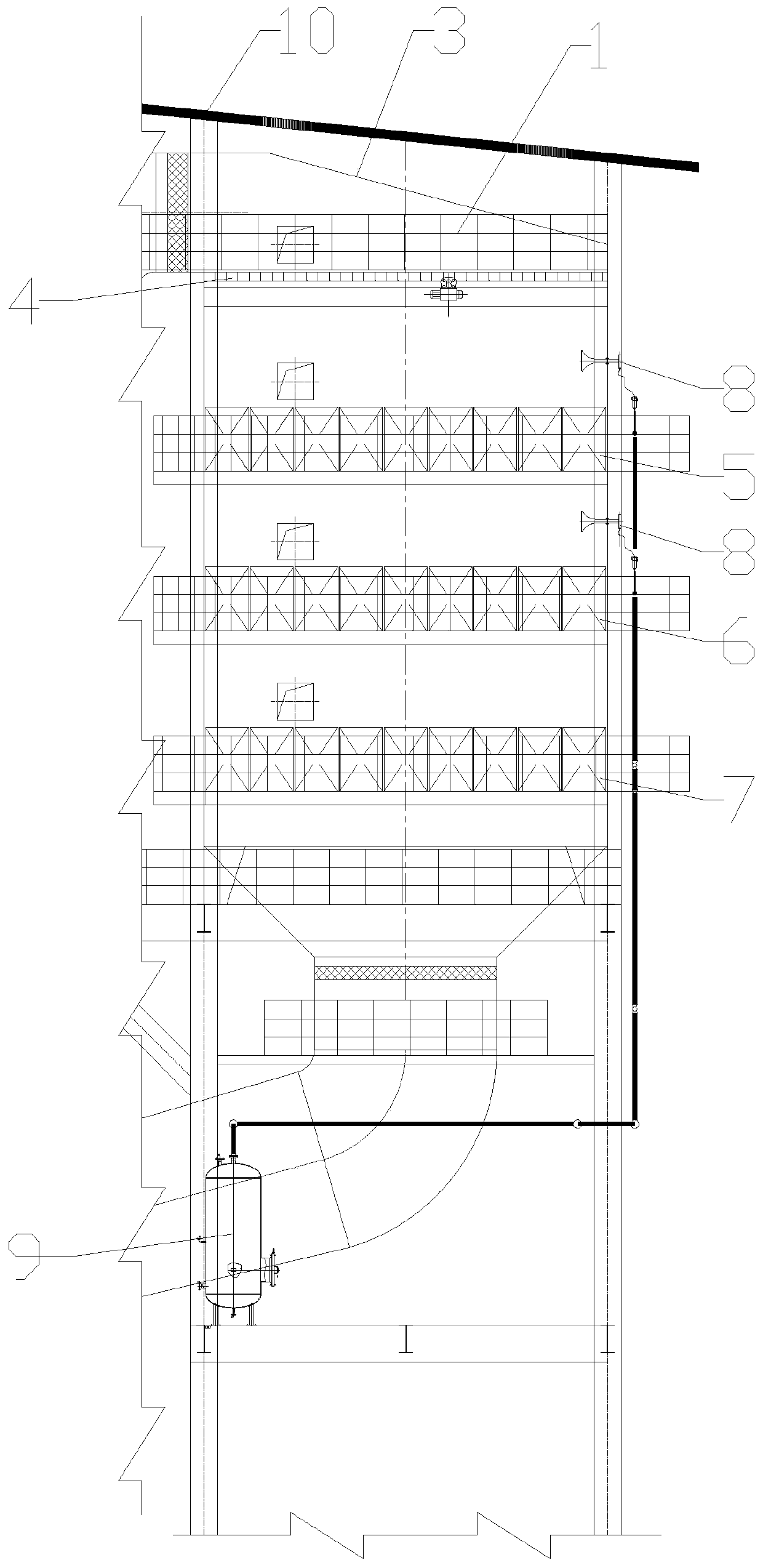

[0030] see figure 1 , the present invention relates to a flue gas denitrification system, which includes an ammonia water storage tank 11, an ammonia water delivery pump 12, an ammonia water evaporation tank 13, a tar adsorption device 14, a hot blast stove 15, an ammonia injection grid 2 and a reactor body 1;

[0031] Pass into the ammoniacal liquor of 20% concentration in the ammoniacal liquor storage tank 11, the outlet of ammoniacal liquor storage tank 11 is connected with the inlet of ammoniacal liquor delivery pump 12, the outlet of ammoniacal liquor delivery pump 12 is connected with the inlet of ammoniacal liquor evaporator 13, the outlet of ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com