PVC insulated sheathed control cable

A polyvinyl chloride and control cable technology, applied in the direction of insulated cables, insulated conductors, inorganic insulators, etc., can solve the problems of accelerated aging rate of cables, untimely heat dissipation of cables, shortened lifespan, etc., and achieve accelerated heat dissipation rate and thermal insulation performance. The effect of low, strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

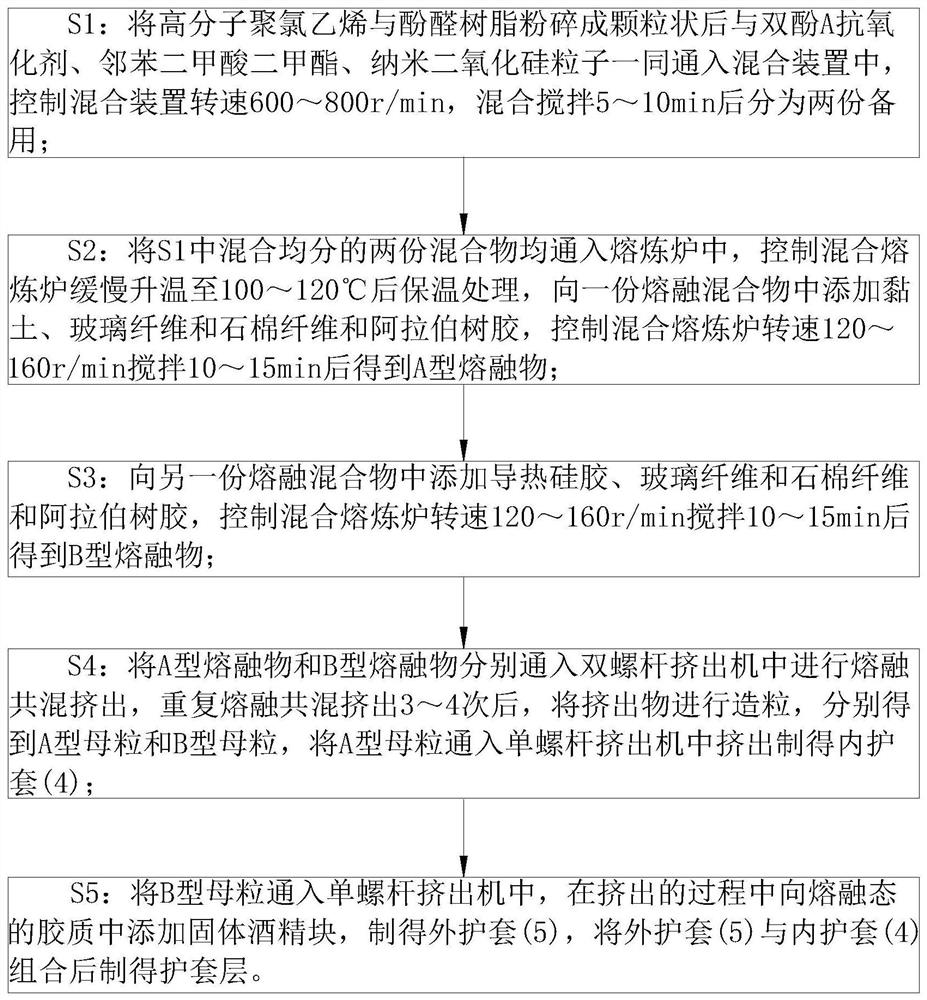

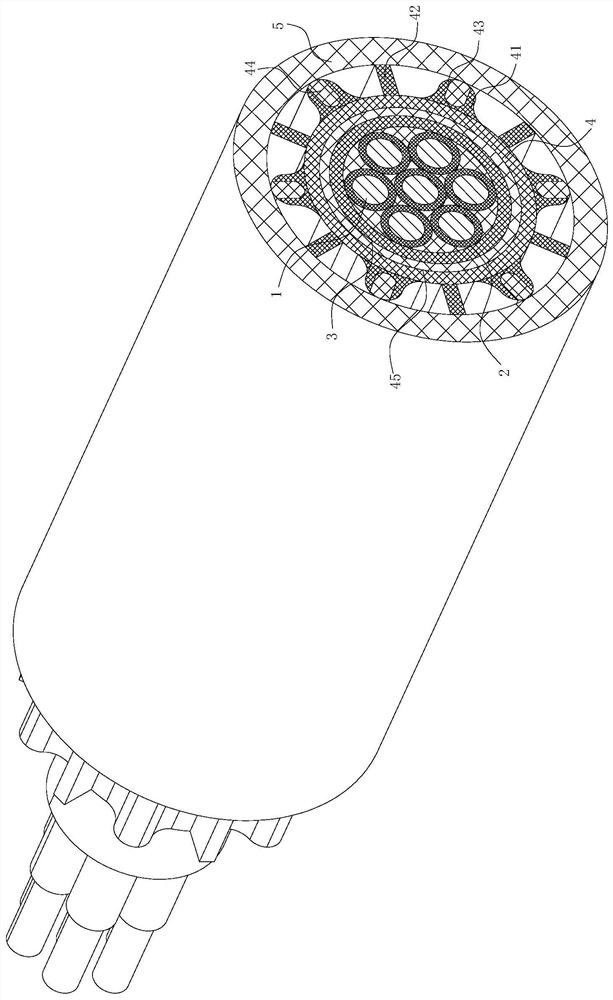

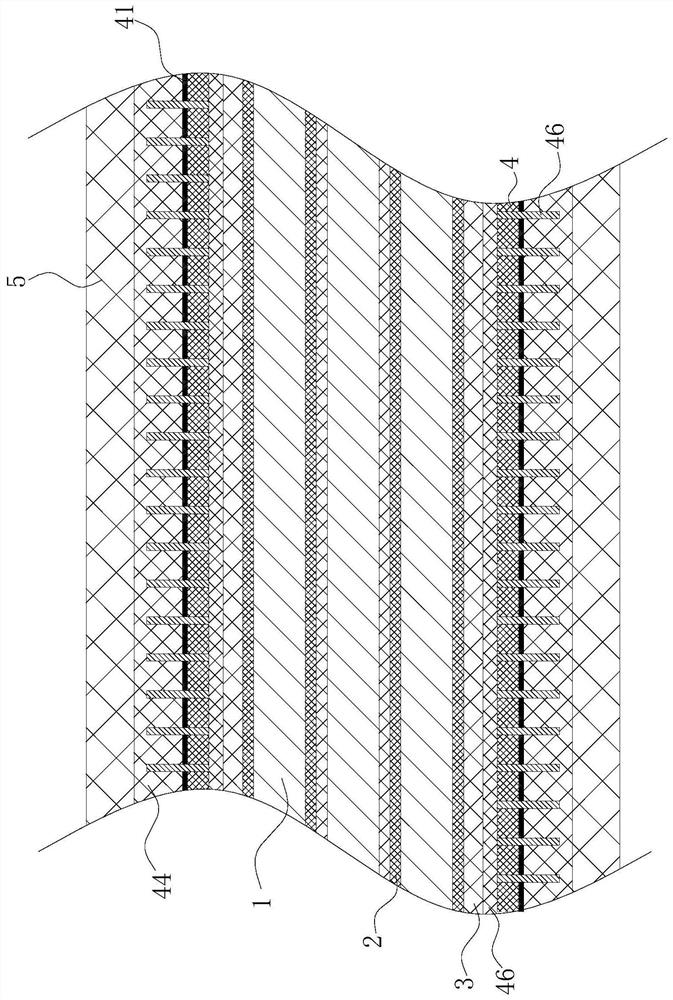

[0034] Such as figure 1 As shown in the figure, the polyvinyl chloride insulated sheathed control cable of the present invention includes a sheath layer; the sheath layer is composed of the following raw materials:

[0035] 82-88 parts by weight of high-molecular polyvinyl chloride, 20-25 parts by weight of phenolic resin, 6-8 parts by weight of asbestos fiber, 6-8 parts by weight of glass fiber, 3-5 parts by weight of gum arabic, and 5-6 parts by weight of thermal conductive silicone grease 10-12 parts by weight of clay, 0.5-1.2 parts by weight of bisphenol A antioxidant, 1.5-3.5 parts by weight of dimethyl phthalate;

[0036] The phenolic resin selected in the raw material is a synthetic plastic with excellent heat resistance, flame resistance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com