Rotary valve type sonic blowing ash device

A technology of sonic soot blower and rotary valve, which is applied in the direction of sound-emitting devices, instruments, and combustion product treatment. It can solve the problems of inability to rotate at high speed, jamming of impurities, and failure to work, and achieve long-term stable operation, long service life, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The working principle of the present invention is as follows:

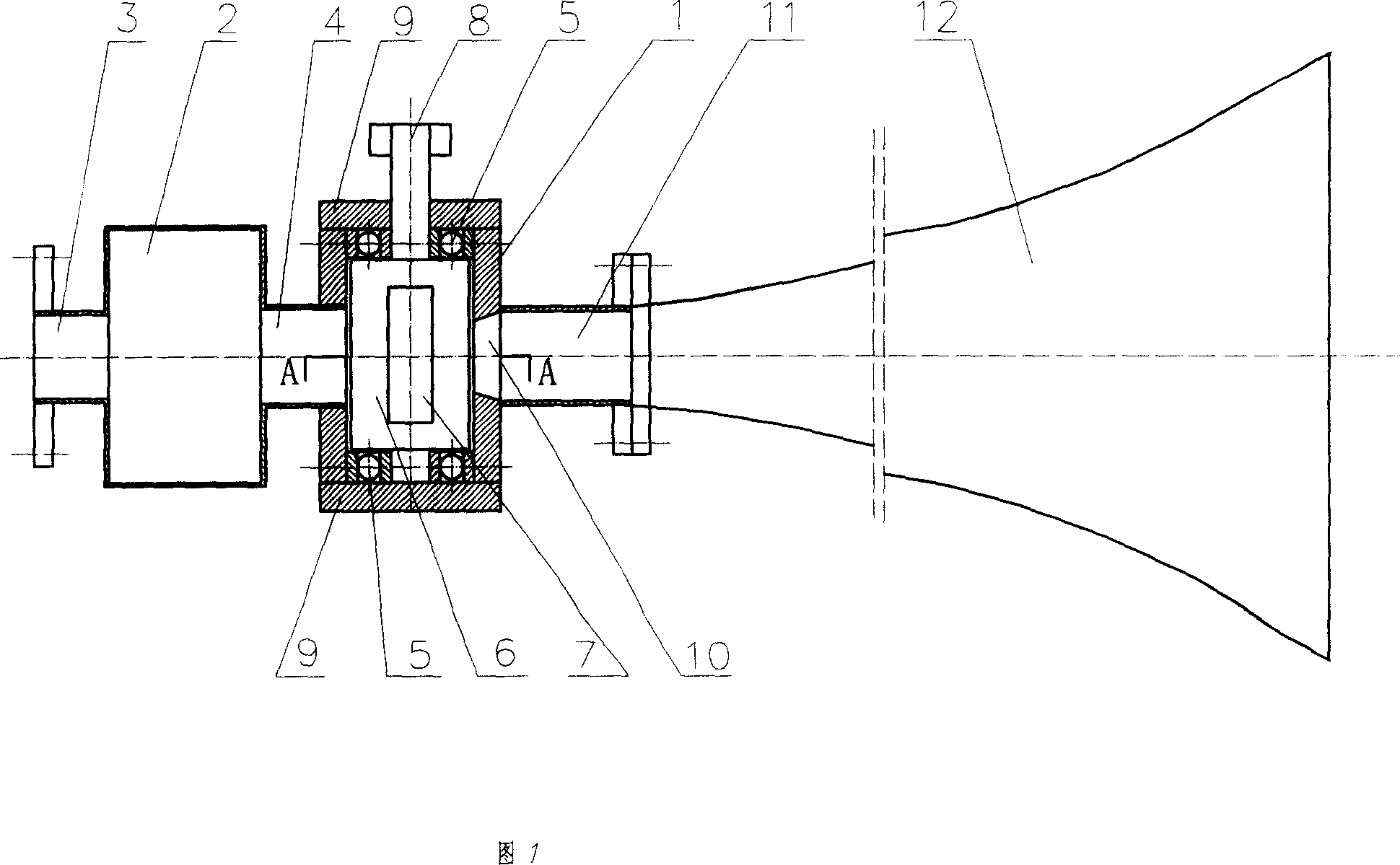

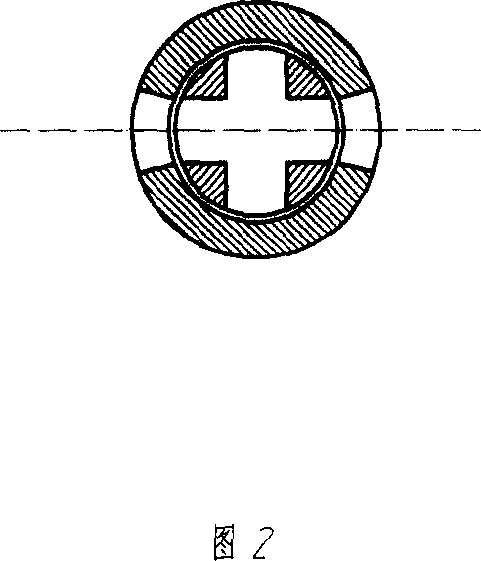

[0010] The high-pressure airflow enters the stator 1 from the air inlet pipe 3 through the air chamber 2. Since the rotor 6 is placed in the stator 1, the rotor 6 is supported by the bearing 5. In this way, the rotor 6 can be driven by the rotor shaft 8 to rotate at a high speed in the stator 1. The rotor 6 is provided with a square or rectangular hole or slot 7, and the cross section of the spout 10 is circular. According to the principle of kinematics, the relative motion of the two holes intersects, and the flow area of the spout 10 changes according to the sine law. In this way, the change of the air flow also changes according to the sine law, that is, the high pressure air flow is modulated into a pressure pulse that changes according to a sine wave, so that the air flow ejected from the nozzle 10 is intermittently on and off, and becomes a pulse state. The pulse frequency is generally 100-300kz, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com