Industrial glass fiber fabric coating device

A glass fiber, coating device technology, applied in the device, coating, textile and paper making of the surface coating liquid, can solve the problems affecting the quality of the finished product, air bubbles, function and single structure, etc., to avoid the suction force Insufficient, high dust removal efficiency, good coating quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

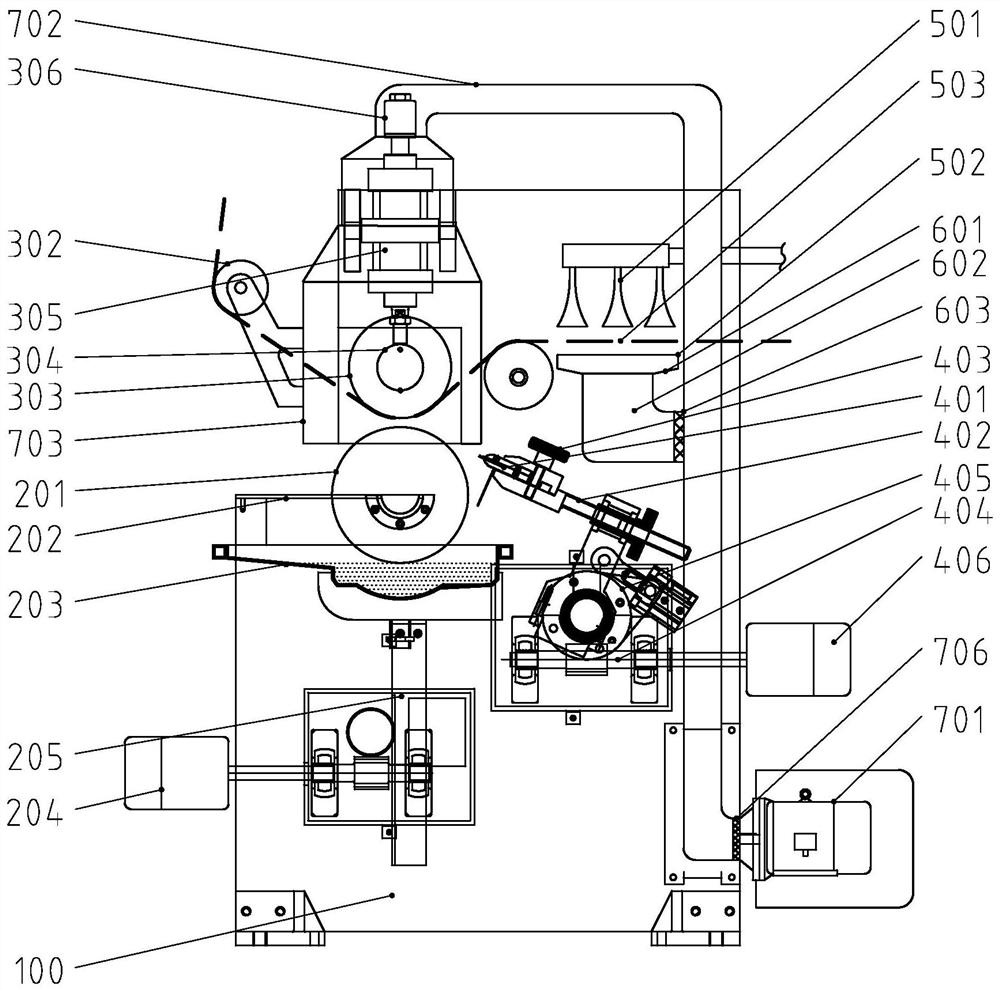

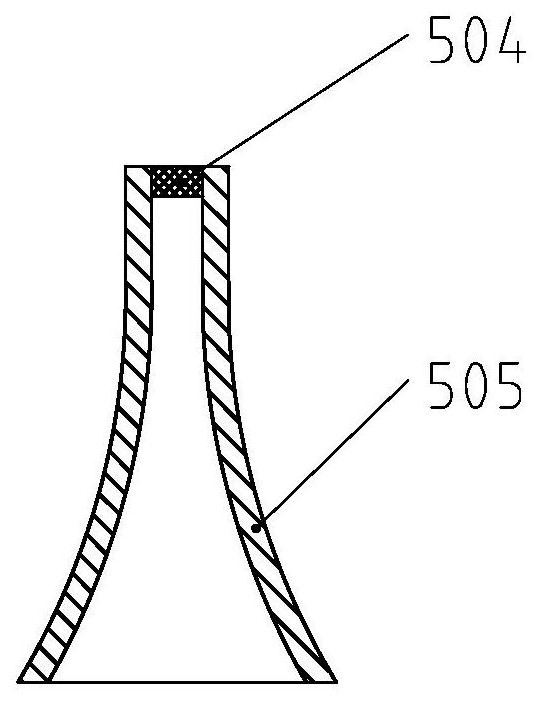

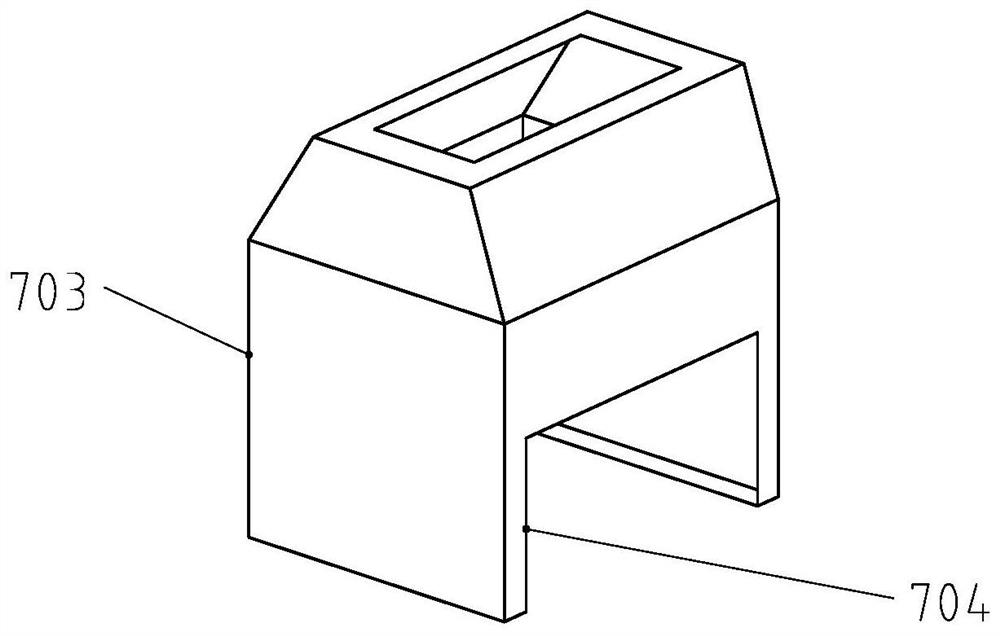

[0026] Such as figure 1 An industrial glass fiber fabric coating device shown includes a frame 100 and a coating roller assembly arranged on the frame, a feeding roller assembly, a thickness-setting doctor blade assembly, a front ash removal assembly and a negative pressure assembly, and the feeding roller The assembly is arranged above the coating roller assembly, the thickness-setting scraper assembly is arranged on the side of the coating roller assembly, and the front ash removal assembly is arranged on the feeding side of the feeding roller assembly. The function of the negative pressure component is to generate negative pressure at the coating working part of the glass fiber fabric, so that the residual air bubbles in the polymer solution at the coating site can be quickly precipitated, so that the quality of the final coating is better, and the air suction direction is From the coating layer of the glass fiber fabric to the back of the fabric, after the polymer solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com