Novel multi-medium sound wave soot blower

A sonic soot blower and multi-media technology, which is applied in the direction of combustion product treatment, combustion method, and solid residue removal, can solve the problems of inconvenient spray angle adjustment, inconvenient nozzle swing, and reduced application range, so as to improve the application range, ease of adjustment, and improved usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

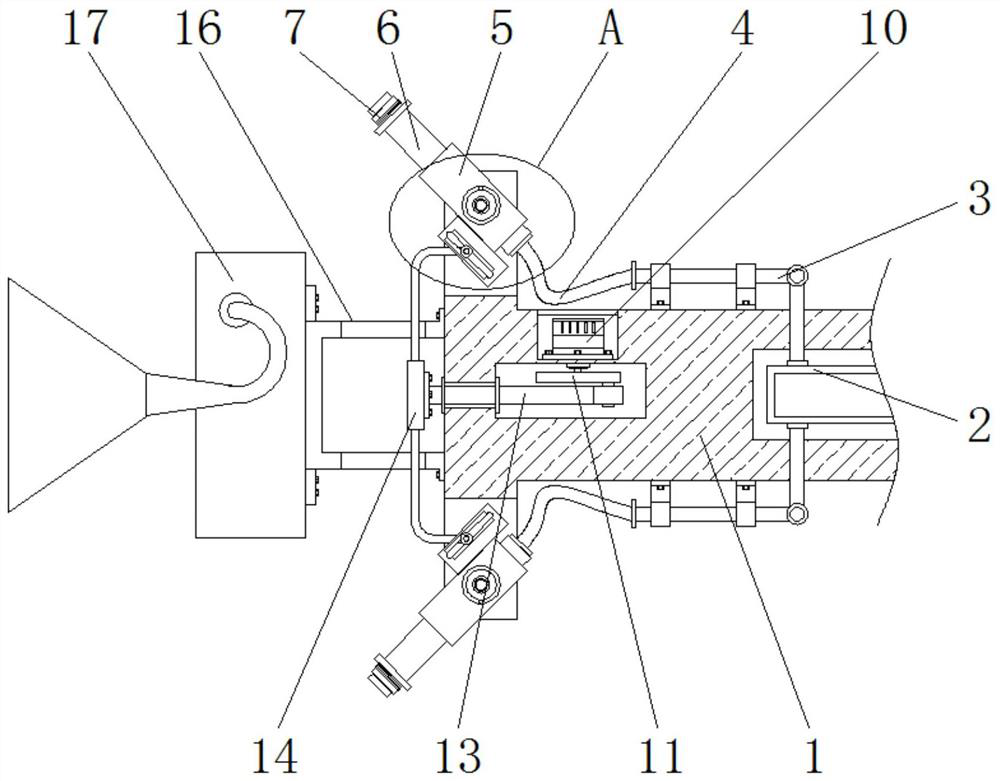

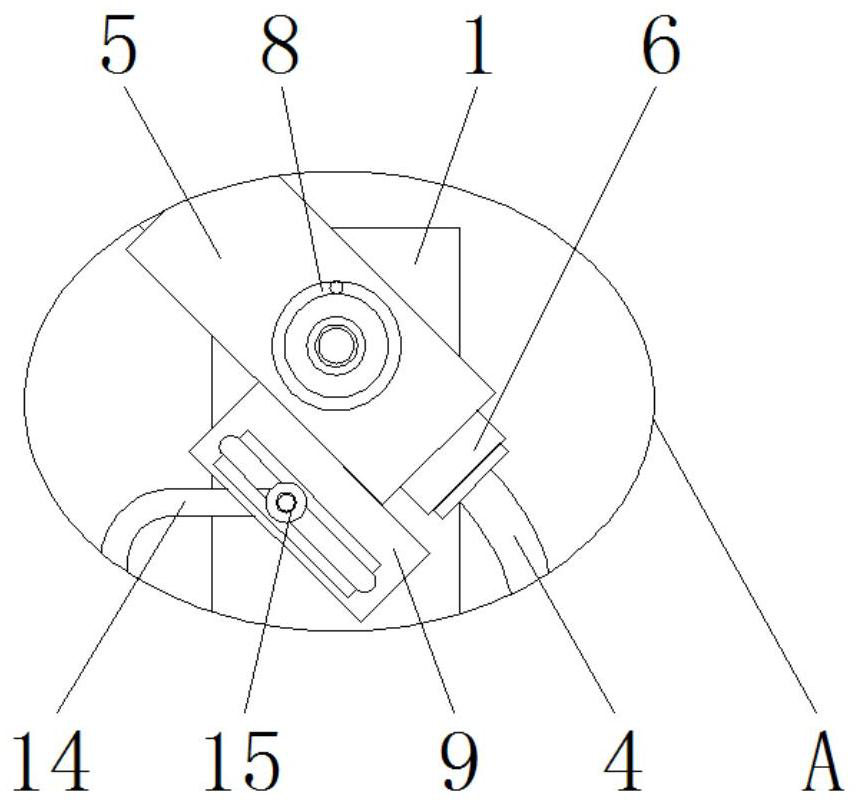

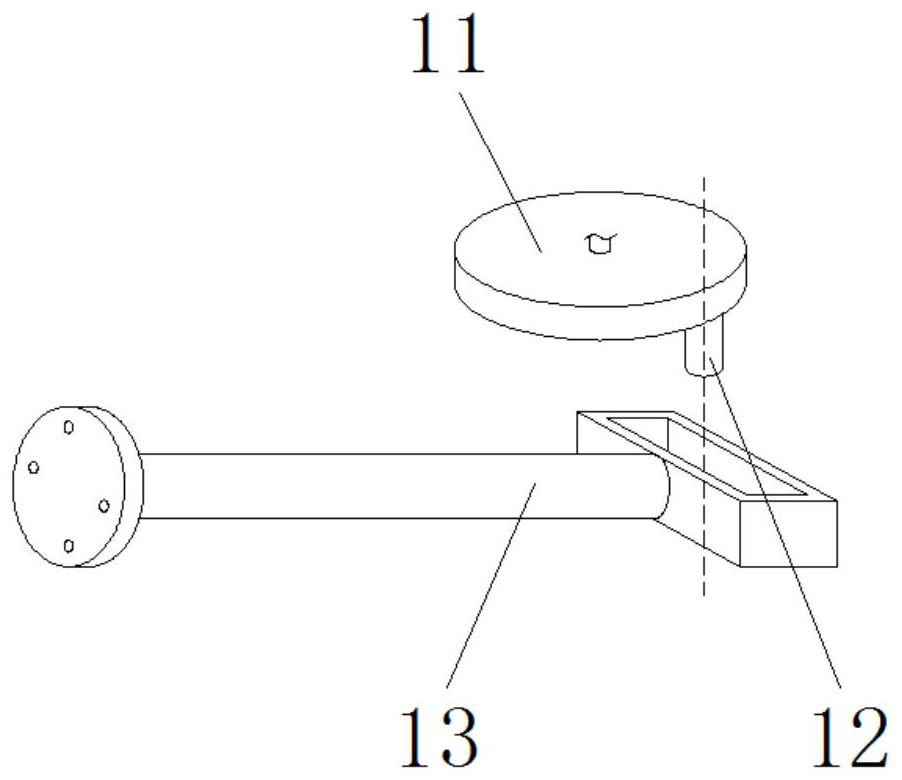

[0021]SeeFigure 1-4The present invention provides a technical solution: a new multi-dielectric acoustic wave peeler, including mounting column 1, conveying tube 2, split pipe 3, hose 4, carrier 5, auxiliary tube 6, sector nozzle 7, The torsion spring 8, the connection frame 9, the servo motor 10, the turntable 11, the fixing column 12, the movable frame 13, the auxiliary frame 14, the roller 15, the mounting frame 16, and the acoustic wave peeler body 17, and the inside of the mounting column 1 is installed in the right end. Tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com