Sound-wave dust-blowing device

A technology of soot blowing device and sound wave, applied in the field of soot blowing device, can solve the problems of high load of rotating shaft bearing, easy to wear turntable, unstable wind shear, etc., and achieve the effect of prolonging life, reducing wear and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

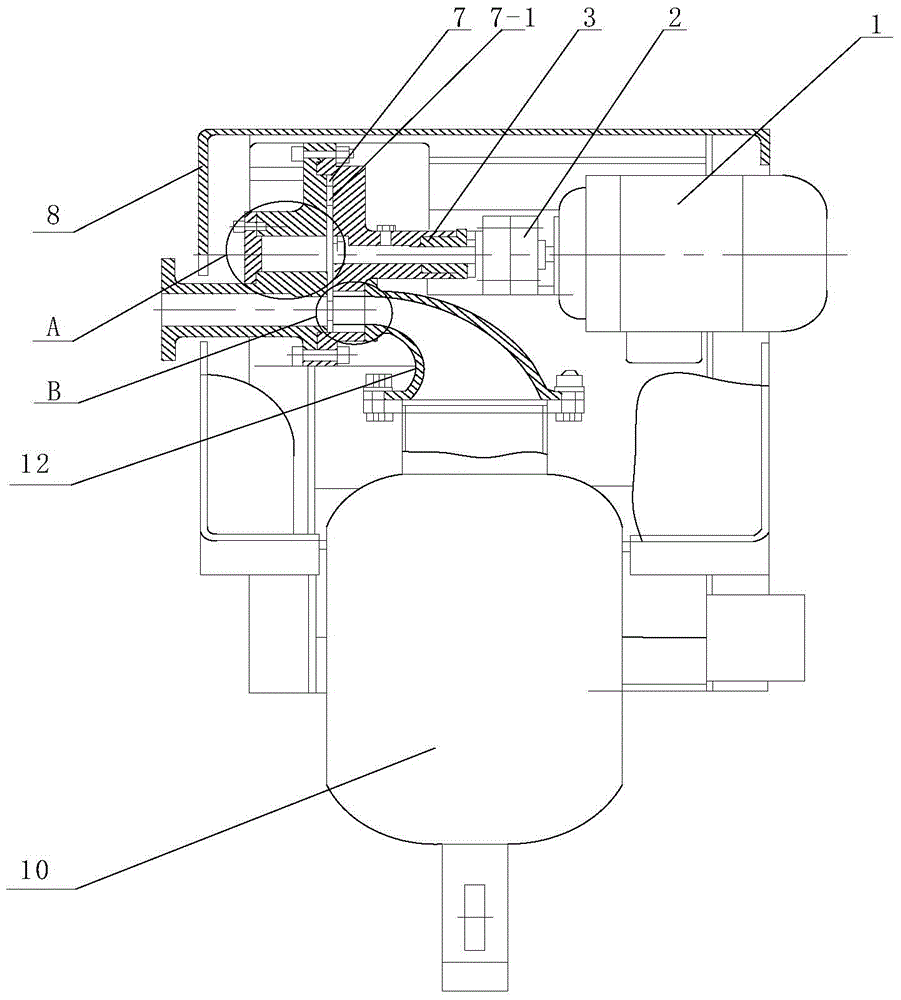

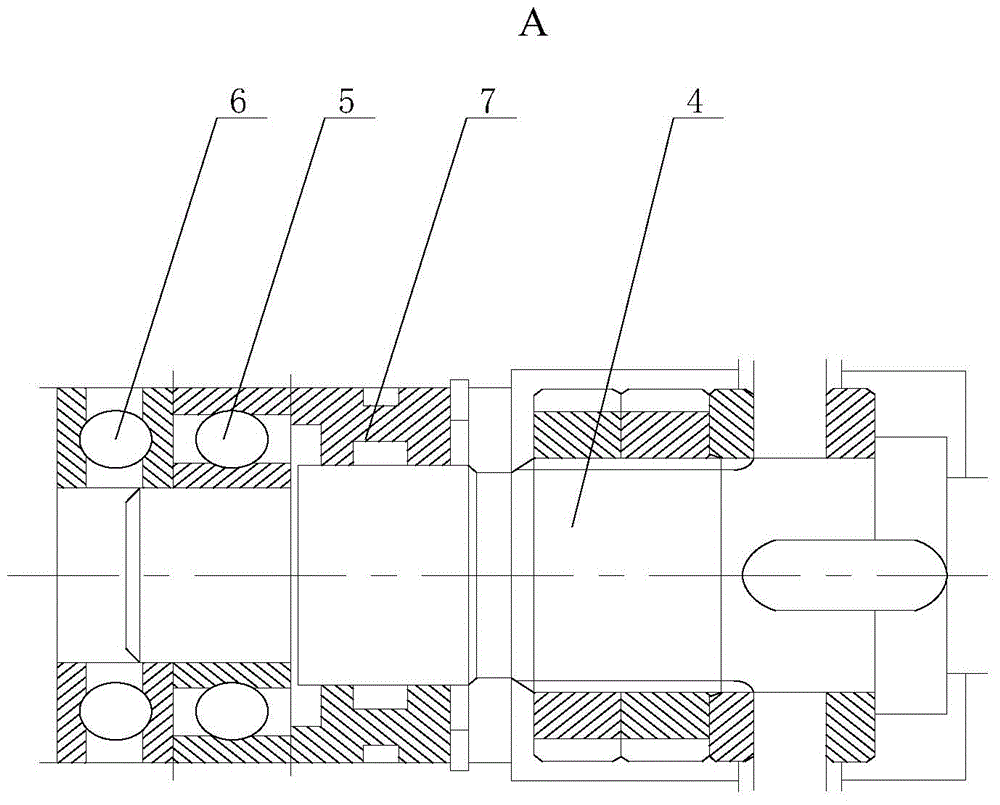

[0010] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, a sonic soot blowing device described in this embodiment includes a driving mechanism, a transmission shaft 4, a rotary bearing 5, a thrust bearing 6, a turntable 7, a casing 8 and an air blowing mechanism, and the driving mechanism is installed in the casing In the upper part of the body 8, one end of the transmission shaft 4 is connected to the drive mechanism, and the turntable 7, the rotary bearing 5, and the thrust bearing 6 are sequentially set on the transmission shaft 4 from one end to the other end of the transmission shaft 4, and the turntable 7 is evenly arranged with A plurality of air holes 7-1, the blowing mechanism is installed in the casing 8, and the air holes 7-1 on the turntable 7 are tangent to the airflow generated by the blowing mechanism.

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the driving mechanism of a sonic soot blowing device described in this embodiment includes a motor 1, a frequency converter 2 and a coupling 3, the frequency converter 2 is connected to the motor 1, and the rotating shaft of the motor 1 passes through the coupling 3 Connect with one end of transmission shaft 4. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

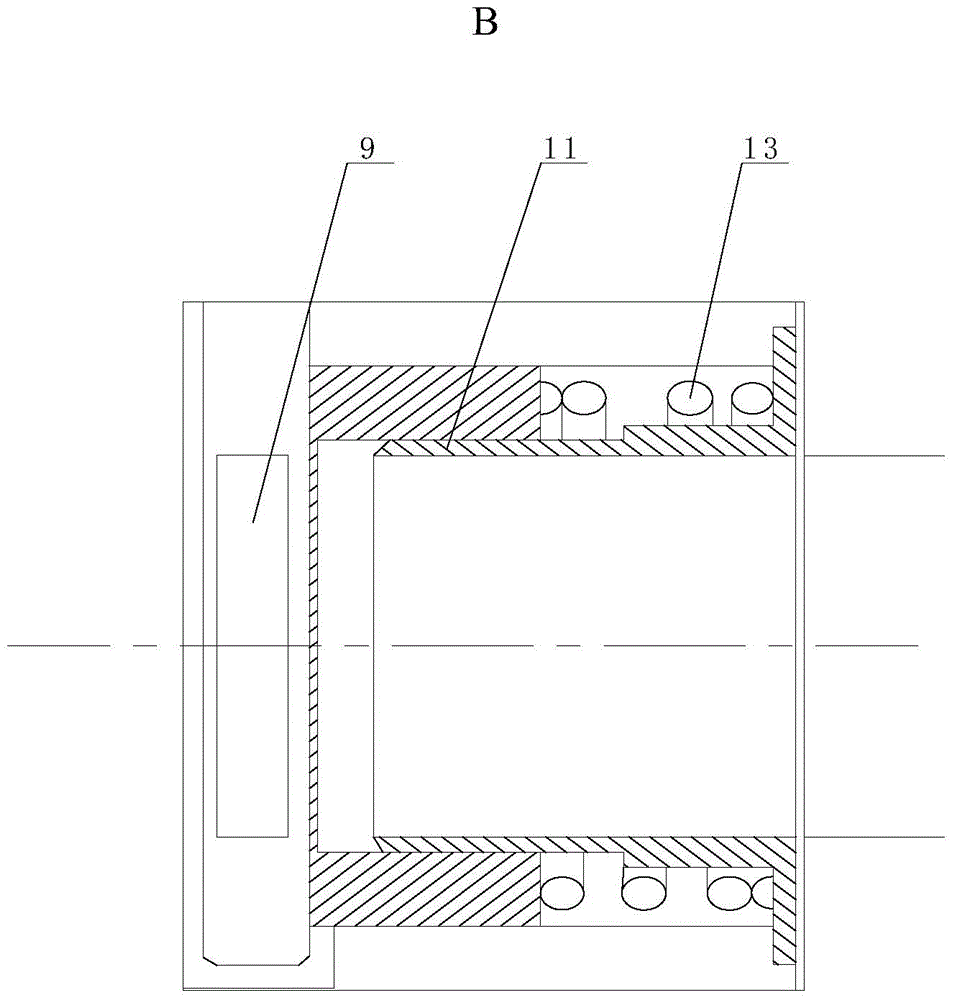

[0012] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the air blowing mechanism of a kind of sound wave soot blowing device described in this embodiment includes air blowing pipe 9, air tank 10, air supply pipe 11 and sonic air flow horn line pipe 12, the air outlet of air tank 10 and the sonic air flow horn The air inlet of the line pipe 12 is connected, the air outlet of the sound wave airflow horn line pipe 12 is connected with one end of the air blowing pipe 9 through the air supply pipe 11, the other end of the air blowing pipe 9 passes through the casing 8 to leak out, and the edge of the turntable 7 is inserted At the junction of the air supply pipe 11 and the air blow pipe 9 , the air hole 7 - 1 on the turntable 7 is tangent to the airflow in the air supply pipe 11 and the air blow pipe 9 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com