Ship propulsion motor online vibration monitoring system

A vibration monitoring system and propulsion motor technology, applied in the field of monitoring systems, can solve problems such as threats to the personal safety of the crew in the safe operation of ships, inability to predict mechanical failures of motors, etc., so as to reduce unplanned downtime, avoid unexpected or catastrophic failures, The effect of reducing stoppage losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

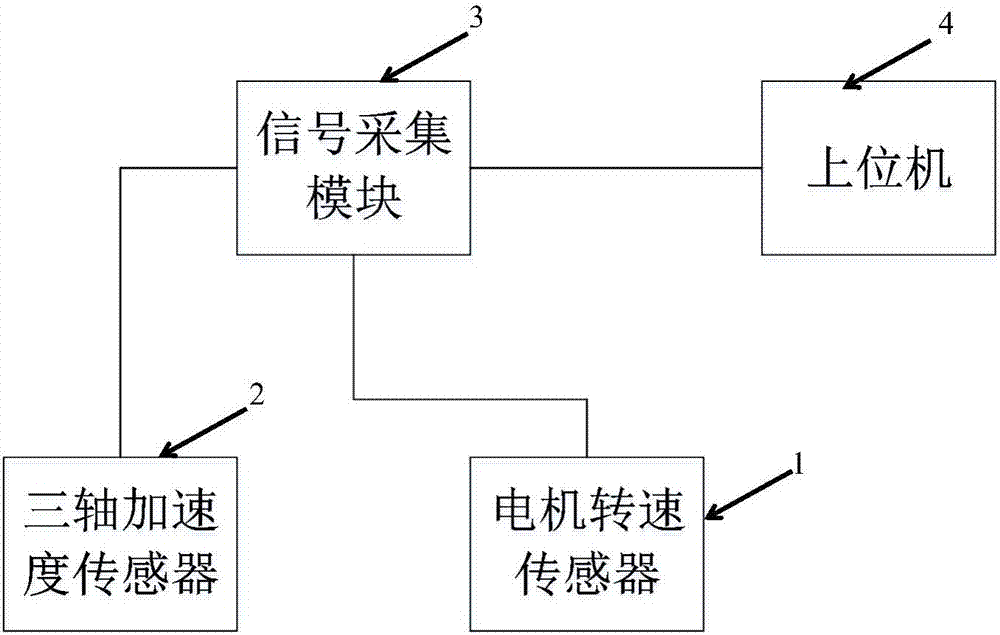

[0022] figure 1 It is a system block diagram of an online vibration monitoring system for a marine propulsion motor in an embodiment of the present invention.

[0023] like figure 1 As shown, the marine propulsion motor online vibration monitoring system has: a motor speed sensor 1, a three-axis acceleration sensor 2, a signal acquisition module 3 and a host computer 4.

[0024] The motor speed sensor 1 is installed on the end cover of the motor on the motor end cover with the gear plate on the shaft, detects the speed of the motor in real time, and converts the speed signal into a speed electric signal.

[0025] The three-axis acceleration sensor 2 is directly installed on the base of the motor, as close as possible to the drive end bearing of the motor, and detects the vibration acceleration of the motor in the axial (X), radial (Y) and vertical (Z) directions in real time , and convert the vibration acceleration signal into an acceleration electrical signal.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com