Vibrating screen crossbeam fault detection device and method

A technology of fault detection and detection method, applied in the direction of material magnetic variables, etc., can solve the problems of inaccurate detection results, high production cost, slow detection speed, etc., and achieve the effect of reducing economic losses, low cost, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

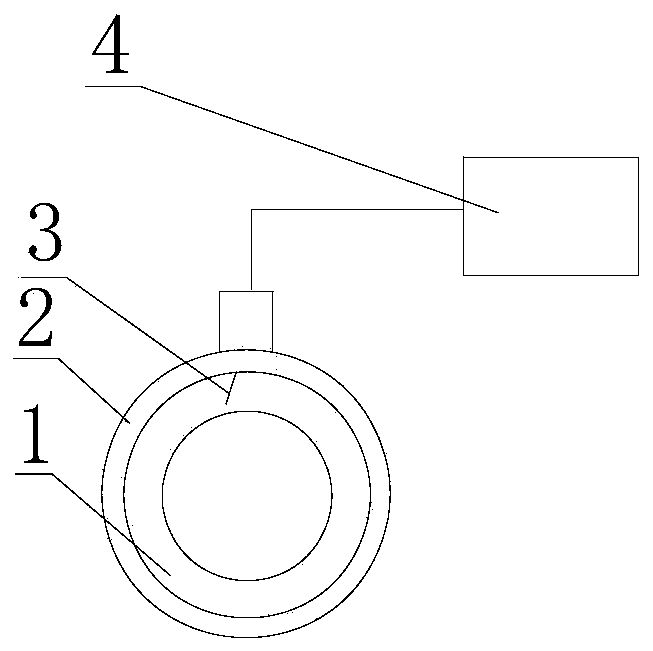

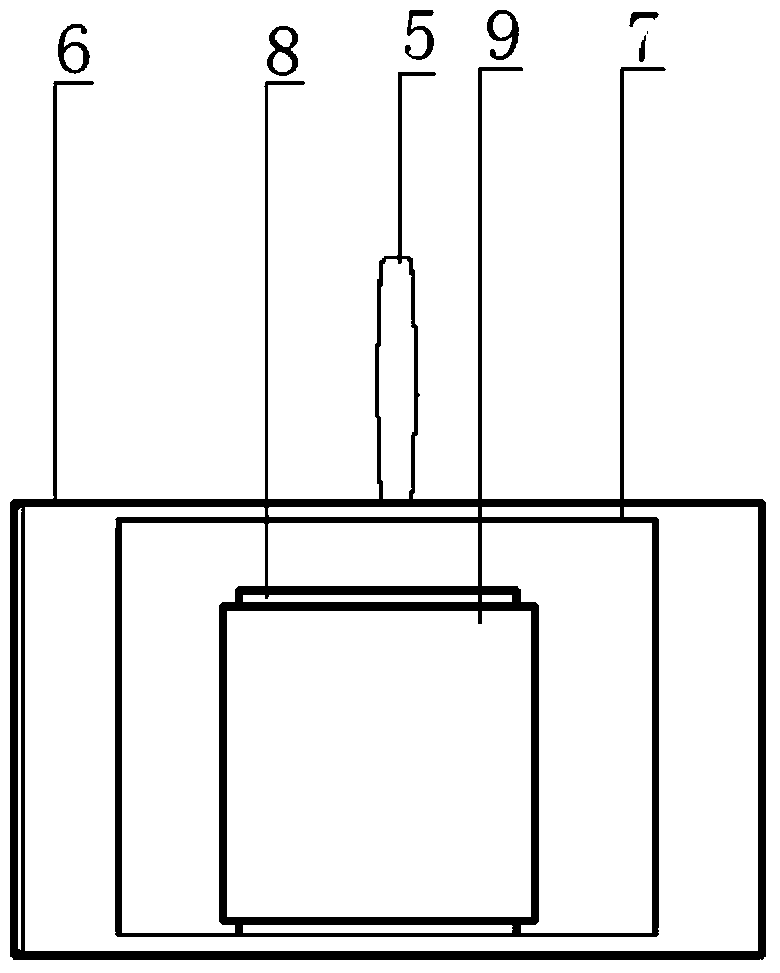

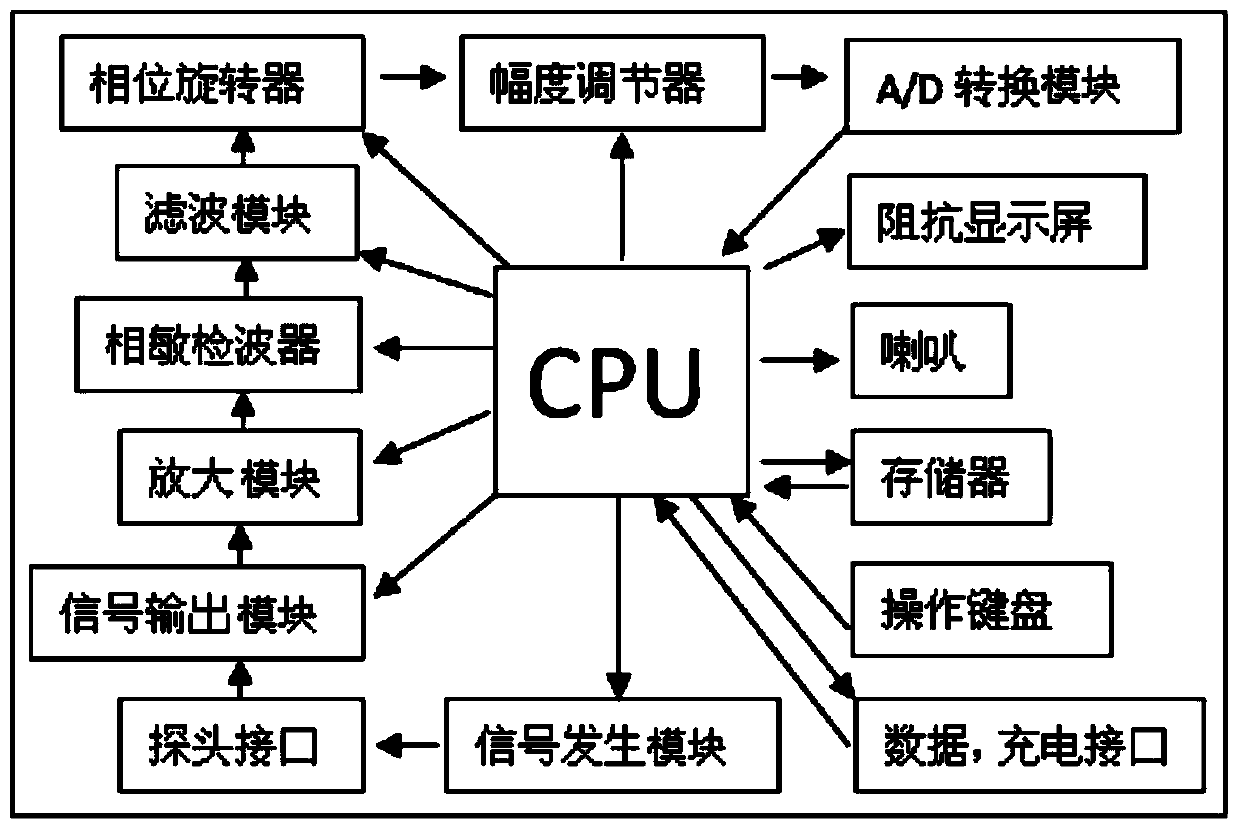

[0023] like Figure 1-4 As shown, a vibrating screen girder fault detection device and detection method described in the embodiment of the present invention includes a low-frequency eddy current detection host 4, a CPU is installed inside the low-frequency eddy current detection host 4, and the CPU is connected to a signal generation module, a probe interface, The signal output module, amplification module, phase-sensitive detector, filter module, phase rotator, amplitude regulator, A / D conversion module, impedance display screen, speaker, memory, operation keyboard and data charging interface are connected, and the probe interface is Insert the probe device. The signal generation module is connected to the probe interface, the probe interface is connected to the signal output module, the signal output module is connected to the amplification module, the amplification module is connected to the phase-sensitive detector, the phase-sensitive detector is connected to the filter m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com