Ship mechanical fault remote detecting device and method

A mechanical failure and remote detection technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of difficult ship maintenance work, waste of manpower, material resources, economic losses, etc., to reduce unplanned downtime and save search costs Time and work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

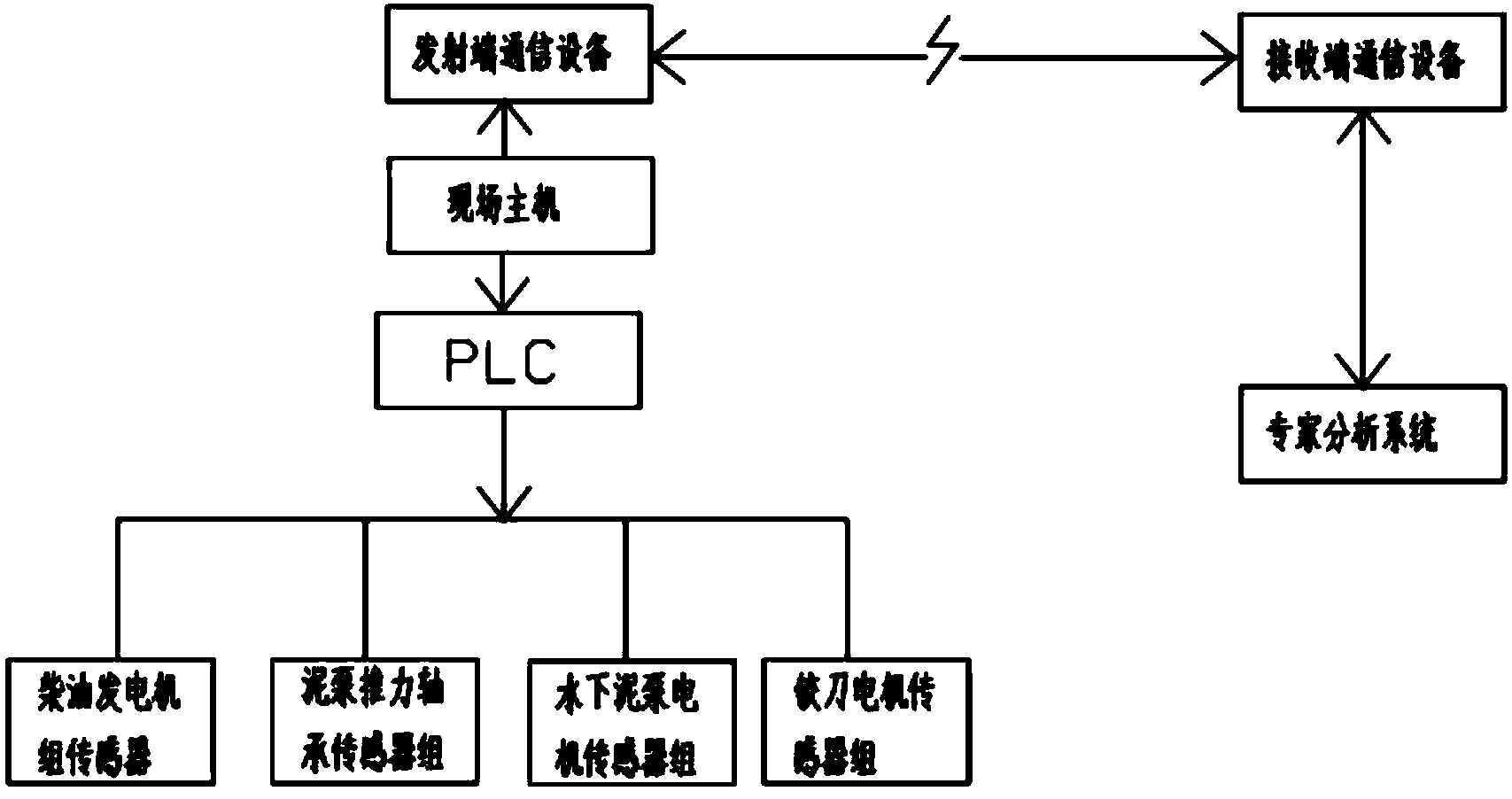

[0040] A remote detection device for ship mechanical failure, such as figure 1 As shown, it includes diesel generator set sensors installed on ships, mud pump thrust bearing sensor sets, underwater mud pump motor sensor sets and reamer motor sensor sets, and a programmable logic controller connected to each sensor to collect and process information from each sensor (PLC) and the on-site host, the on-site host packs and compresses the sensor information processed by the PLC and connects it to the communication device at the transmitter, the communication device at the transmitter sends out the information, the communication device at the receiver receives the information sent by the transmitter, and converts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com