Wind turbine blade image damage detection and positioning method

A wind turbine blade and damage detection technology, which is applied in image analysis, image data processing, computer components, etc., can solve the detection accuracy of detection methods (high false warning rate and missed detection rate, which affect the reliability of wind turbine blade fault detection methods) It can reduce the number of unplanned shutdowns, save manpower and material resources, and achieve the effect of fast recognition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

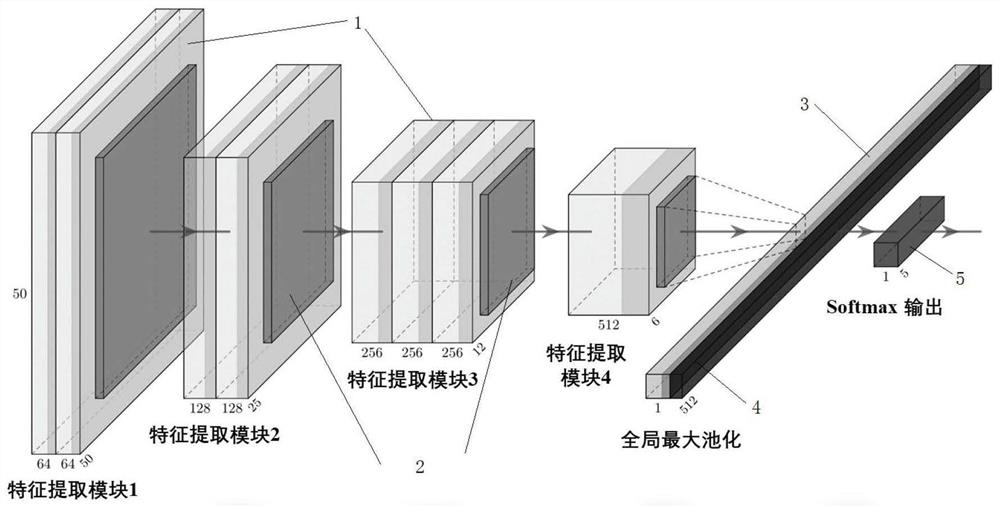

[0058] A method for image damage detection and location of wind turbine blades, based on a deep convolutional neural network, including two processes of model training and damage detection and location:

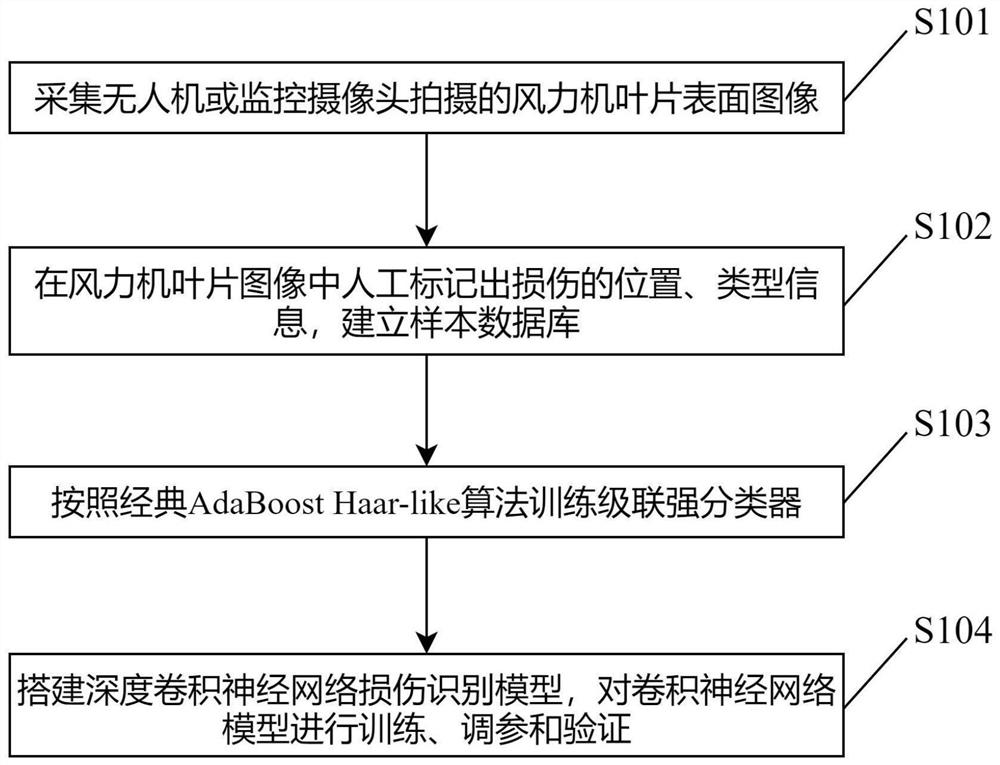

[0059] Among them, such as figure 1 As shown, model training includes the following steps:

[0060] In step S101, a surveillance camera is used to collect images of the surface of the wind turbine blade. The image data used in the embodiment of the present invention all come from a wind farm in eastern China, including a total of 725 surface images of wind turbine blades captured by high-resolution cameras. figure 2 It is a sample of the surface image of the wind turbine blade collected at the wind farm site.

[0061] In step S102, the position and type information of the damage is manually marked on the image of the wind turbine blade, and the image samples containing the damaged area (positive samples) and the image samples of the normal blade surface (negative samples) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com