Rapid replacing system for air pre-filtering device

A pre-filtering and air intake system technology, applied in the field of air intake system, can solve the problems of shorter filter life than the design expected life, increase the number and cost of unplanned downtime to replace the filter screen, and heavy replacement workload, etc. Reliability and economy, reduction of unplanned downtime, excellent working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

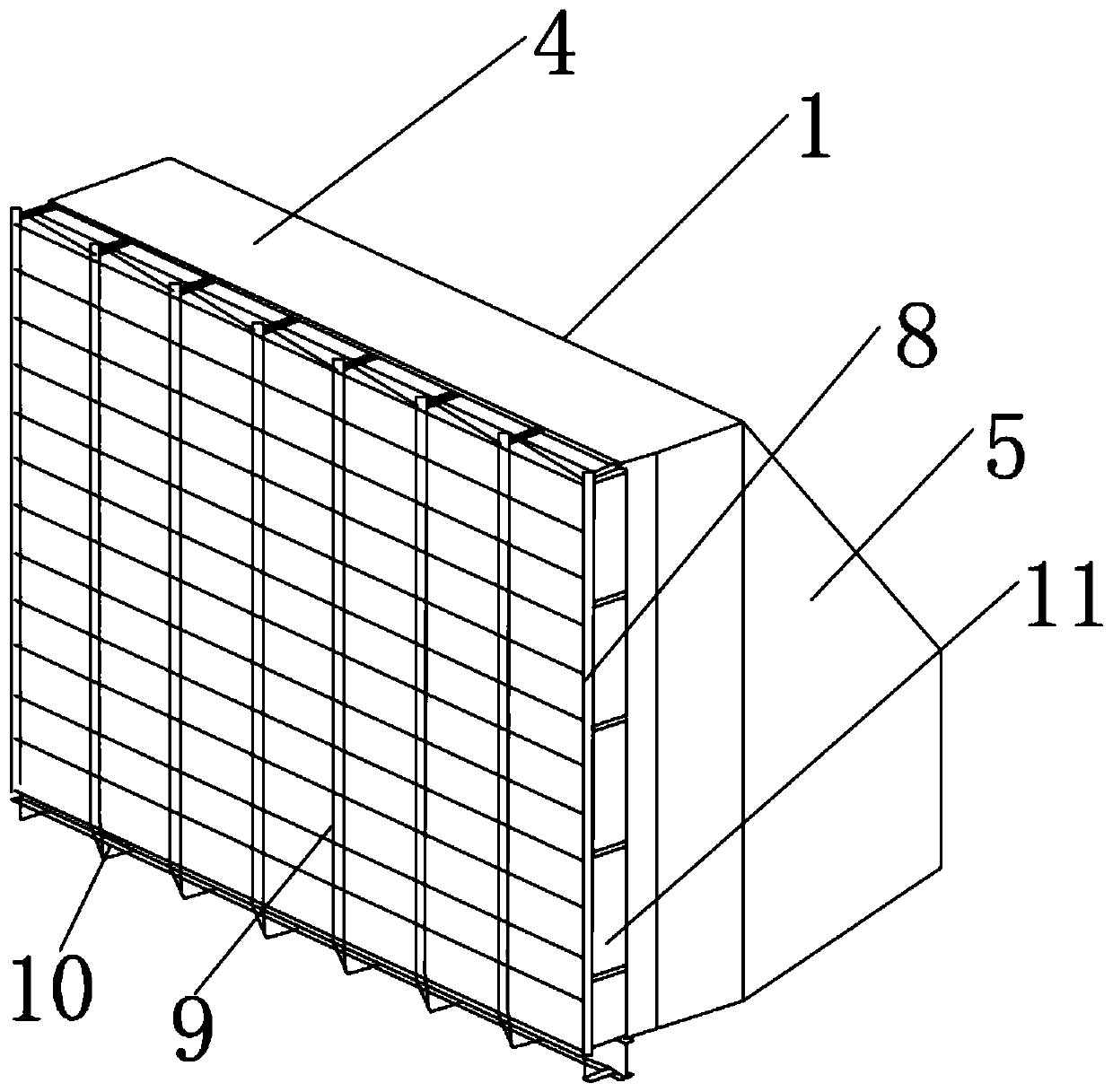

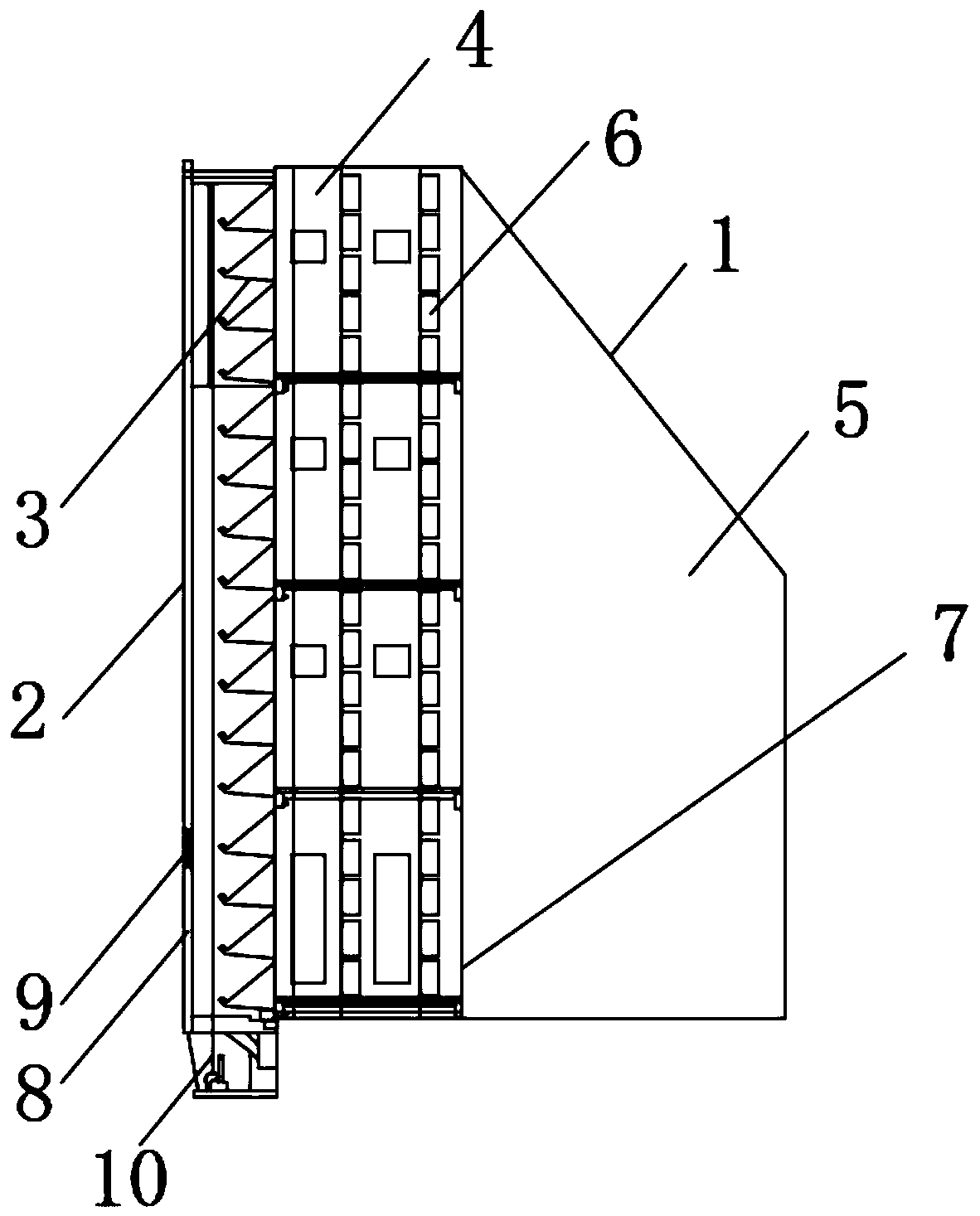

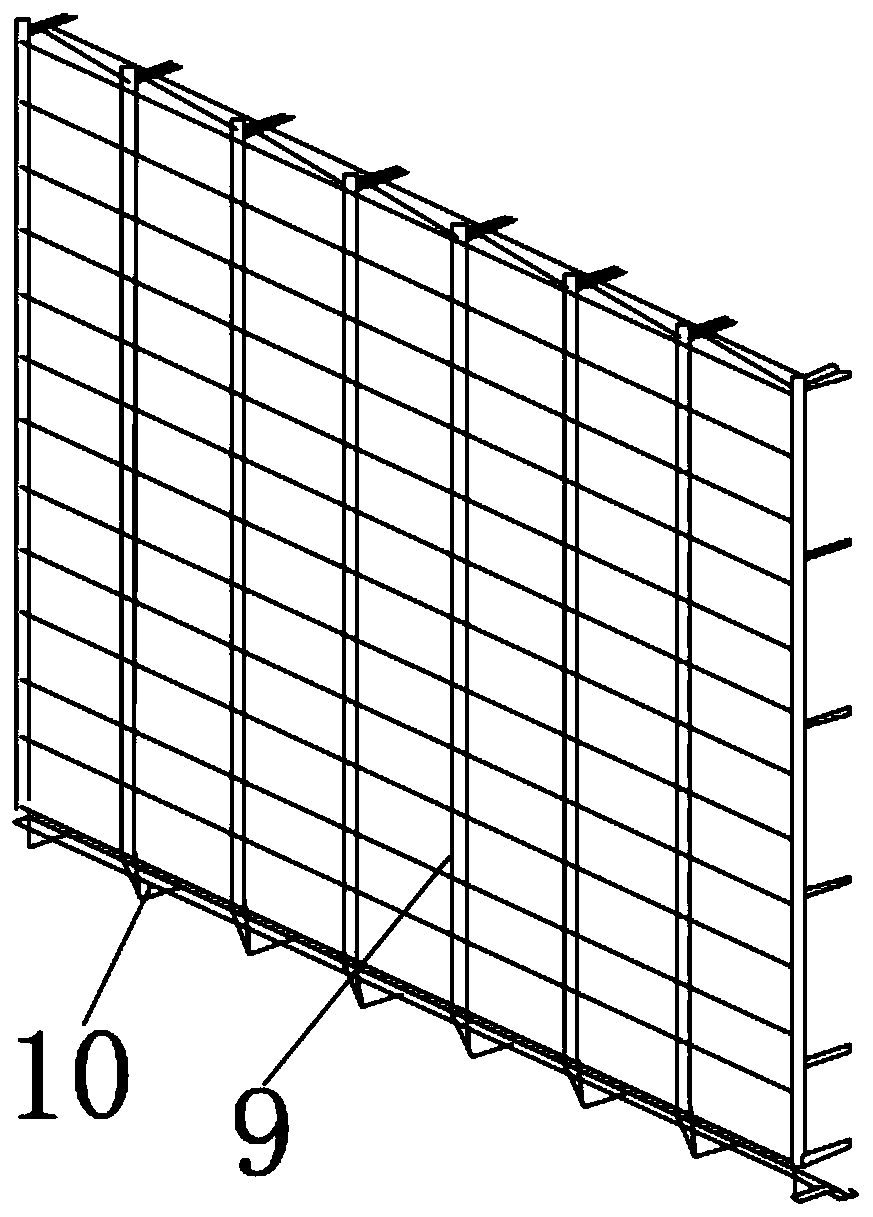

[0029] Such as Figure 1-11 As shown, the embodiment of the present invention provides a quick replacement system for an air pre-filter device. The pre-filter device 2 is installed on the air inlet side of the air intake system 1, and the air enters from the pre-filter device 2, and then passes through the rain-proof The cover 3 enters the filter chamber 4 and is filtered by the main filter element 6, then flows into the clean room 5, and then enters the compressor of the gas turbine. The pre-filter device 2 is connected to the intake frame 7 of the intake system 1 through a series of bottom cantilever beams 15, and the main cantilever beam 16. The support assembly 8 is used to fix and guide the pre-filter module 9 and the lifting mechanism 10 . The supporting assembly 8 is composed of a bottom beam 12, a plurality of bottom cantilever beams 15, several cross bars 14, vertical bars 13, a plurality of main cantilever beams 16, a top beam 17, a top hanger 18 and a bottom bracke...

Embodiment 2

[0031] Such as Figure 1-11 As shown, the embodiment of the present invention provides a quick replacement system for an air pre-filter device, the bottom beam 12 and the bottom cantilever beam 15 are U-shaped aluminum profiles, the vertical rod 13 is an H-shaped aluminum profile with positioning grooves on the surface, and the main cantilever The beam 16 and the top beam 17 are square tubes; the top hanger 18 and the bottom bracket 19 are channel steel. The crossbar 14 is a rectangular aluminum profile, the joints between the bottom crossbeam 12, the vertical pole 13 and the bottom cantilever beam 15 are connected by bolts, and the joints between the crossbar 14, the vertical pole 13 and the main cantilever beam 16 are bolted Connection; Bolt connection between the bottom cantilever beam 15 and the intake frame 7 of the intake system 1 .

Embodiment 3

[0033] Such as Figure 1-11 As shown, the embodiment of the present invention provides a quick replacement system for an air pre-filter device. The vertical pole 13 of the support assembly 8 divides the air intake surface into multiple vertical planes in the transverse direction, and the vertical plane between two adjacent vertical poles 13 is installed A set of lifting mechanism 10 and a pre-filter module 9 are provided. Side sealing plates are installed between the left and right ends of the support assembly 8 and the wall of the air intake system 1, thus forming a complete air pre-filter. The pre-filter element 21 can be installed in the Sliding up and down between the two adjacent poles 13 of the support assembly 8, by starting the hoist 30 of the lifting mechanism 10, the pre-filter modules 9 can be put into operation one by one, or the pre-filter modules 9 can be delisted to the ground or roof without Take scaffolding or other mobile lifting devices; in addition, between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com