Wide-load heat supply energy saving system of back pressure type small turbine driving induced draft fan

An energy-saving system and back-pressure technology, applied in heating systems, hot water central heating systems, household heating, etc. Poor thermal economy and other problems, to achieve the effect of improving work output capacity, ensuring safe start and emergency shutdown functions, and stabilizing heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

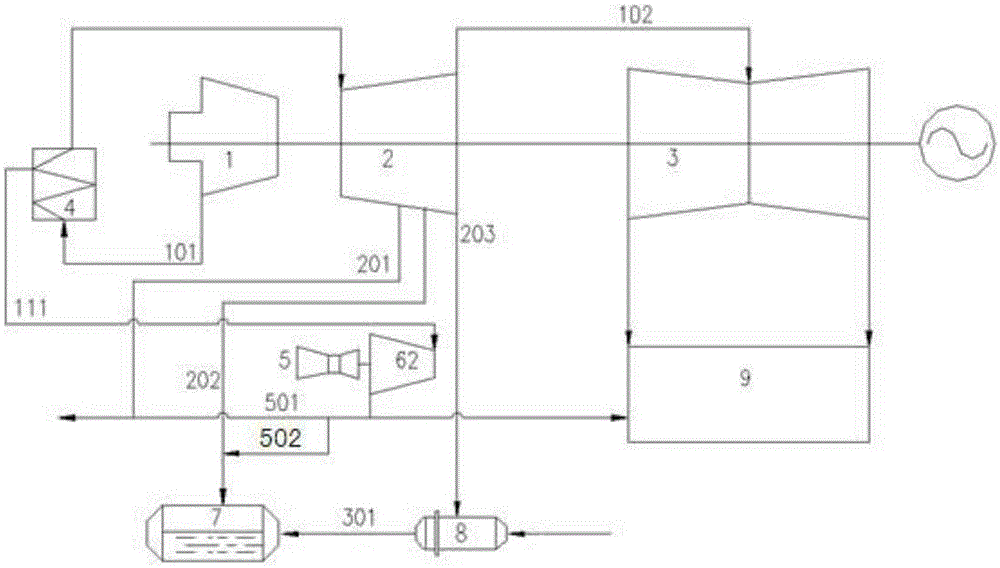

[0026] refer to figure 1 The wide-load heating and energy-saving system of the back-pressure small steam turbine driving the induced draft fan shown includes the main steam turbine, the back-pressure small steam turbine 62, the induced draft fan 5, the boiler reheater 4, the deaerator 7 and the low-pressure heater 8, The main steam turbine is equipped with a high-pressure cylinder 1 and a medium-pressure cylinder 2. The exhaust end of the high-pressure cylinder 1 is connected to the steam inlet end of the boiler reheater 4 through a high-temperature exhaust pipe 101, and one of the outlet ends of the boiler reheater 4 is connected to The steam inlet end of the medium-pressure cylinder 2 constitutes a reheat circuit; the second steam outlet end of the boiler reheater 4 is connected to the steam inlet end of the back-pressure small steam turbine 62 through a sub-high temperature steam pipe 111 to form a back-pressure small steam turbine. Heat supply circuit; the power output end...

specific Embodiment 2

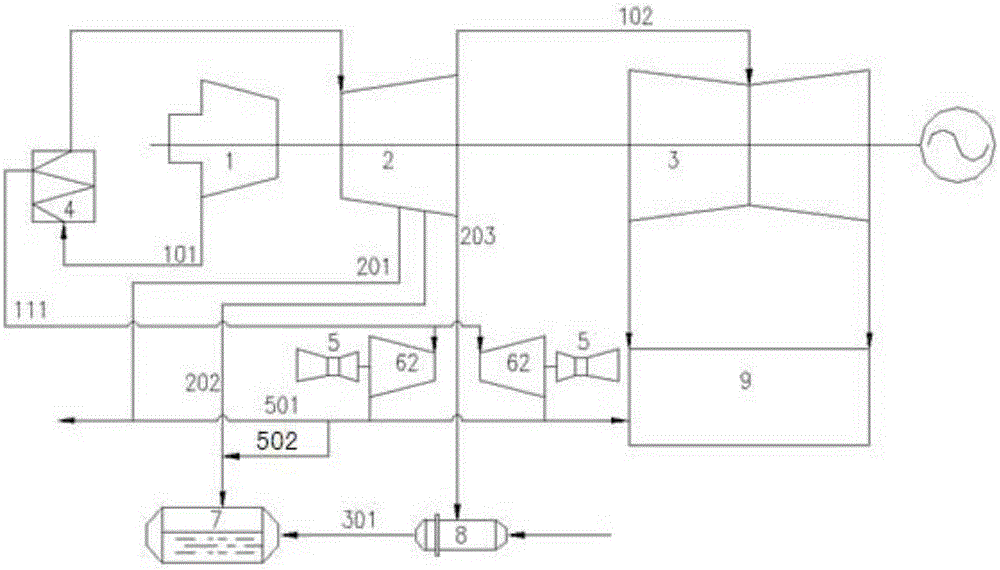

[0028] refer to figure 2 As shown, the technical feature of this embodiment is that the water pump 5 is two 50% capacity driven induced draft fans, and the two 50% capacity driven induced draft fans supply water to two back pressure small steam turbines 62 respectively. All the other are with embodiment 1.

specific Embodiment 3

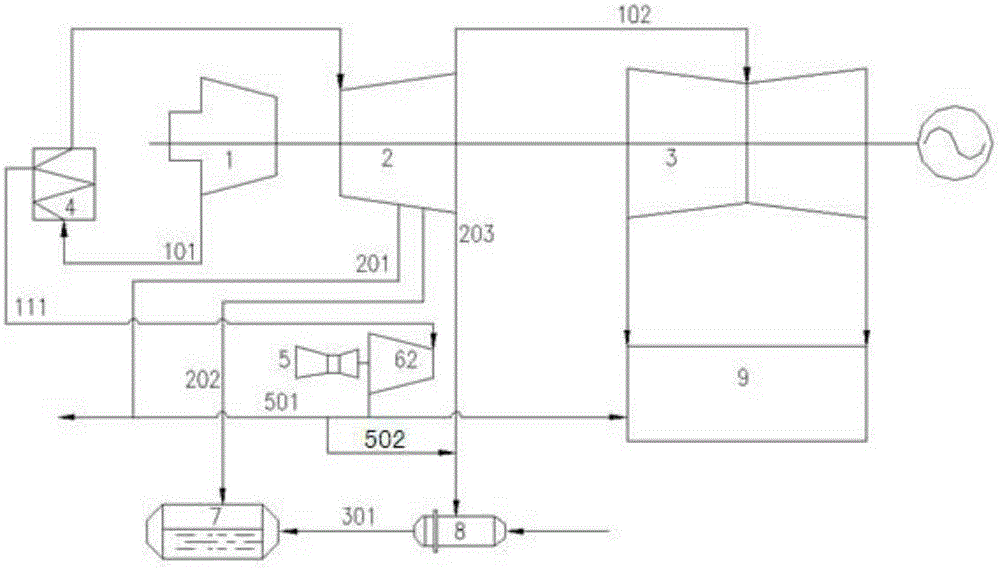

[0029] refer to image 3As shown, the technical features of this embodiment are: the heat supply pipe network 501 communicates with the third exhaust port of the medium-pressure cylinder 2 and the steam inlet end of the low-pressure heater 8 through the steam extraction pipe 201, forming a structure for heating condensed water and The steam extraction and steam intake structure of the heating circuit. The heat supply pipe network 501 is connected to the steam extraction pipe 203 through a switching pipe 502, and the switching pipe 502 is connected to the heat recovery circuit through the steam extraction pipe 203 to form a low-load high heat recovery balance pipe. The induced draft fan 5 is a 100% capacity driven induced draft fan. The low pressure heater 8 is a 100% capacity heater. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com