Rolling mill stand roller replacing device

A technology for rack rolls and rolling mills, which is applied in the direction of metal rolling racks, metal rolling mill stands, lifting devices, etc., and can solve problems such as inability to construct maintenance items, difficult disassembly, and small lower positions of the rolls, so as to reduce unplanned downtime Time, avoid rack roller failure, ensure the effect of installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

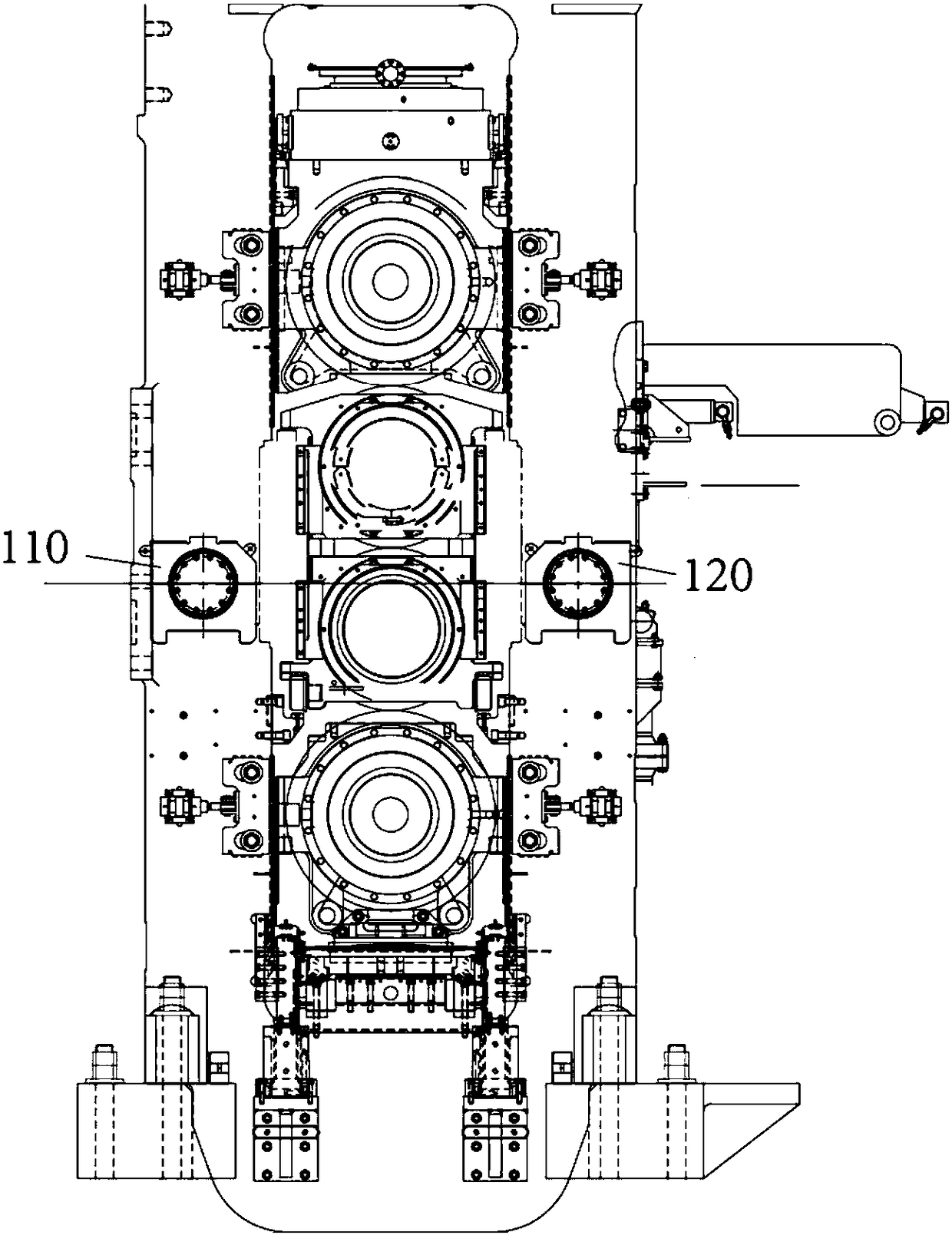

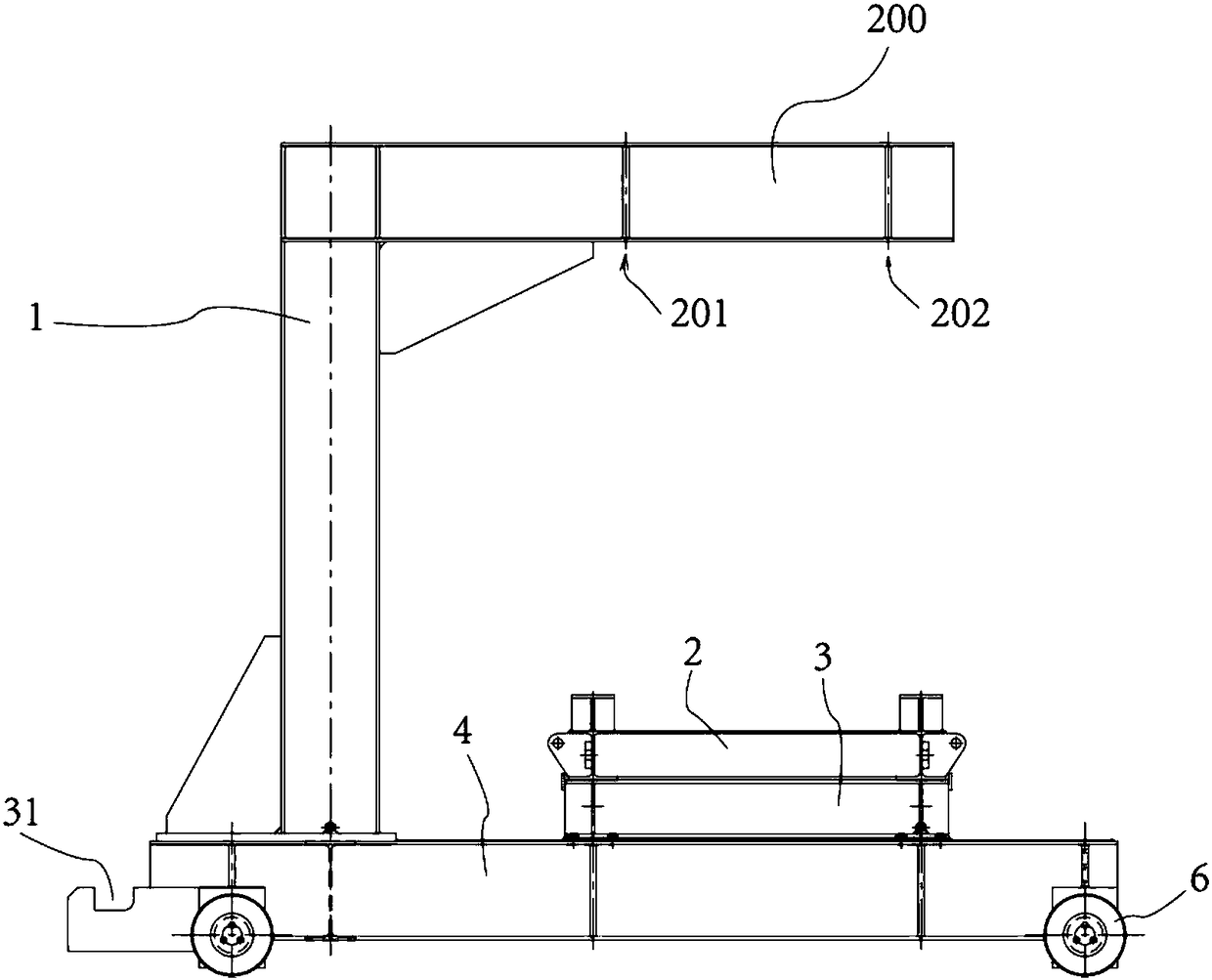

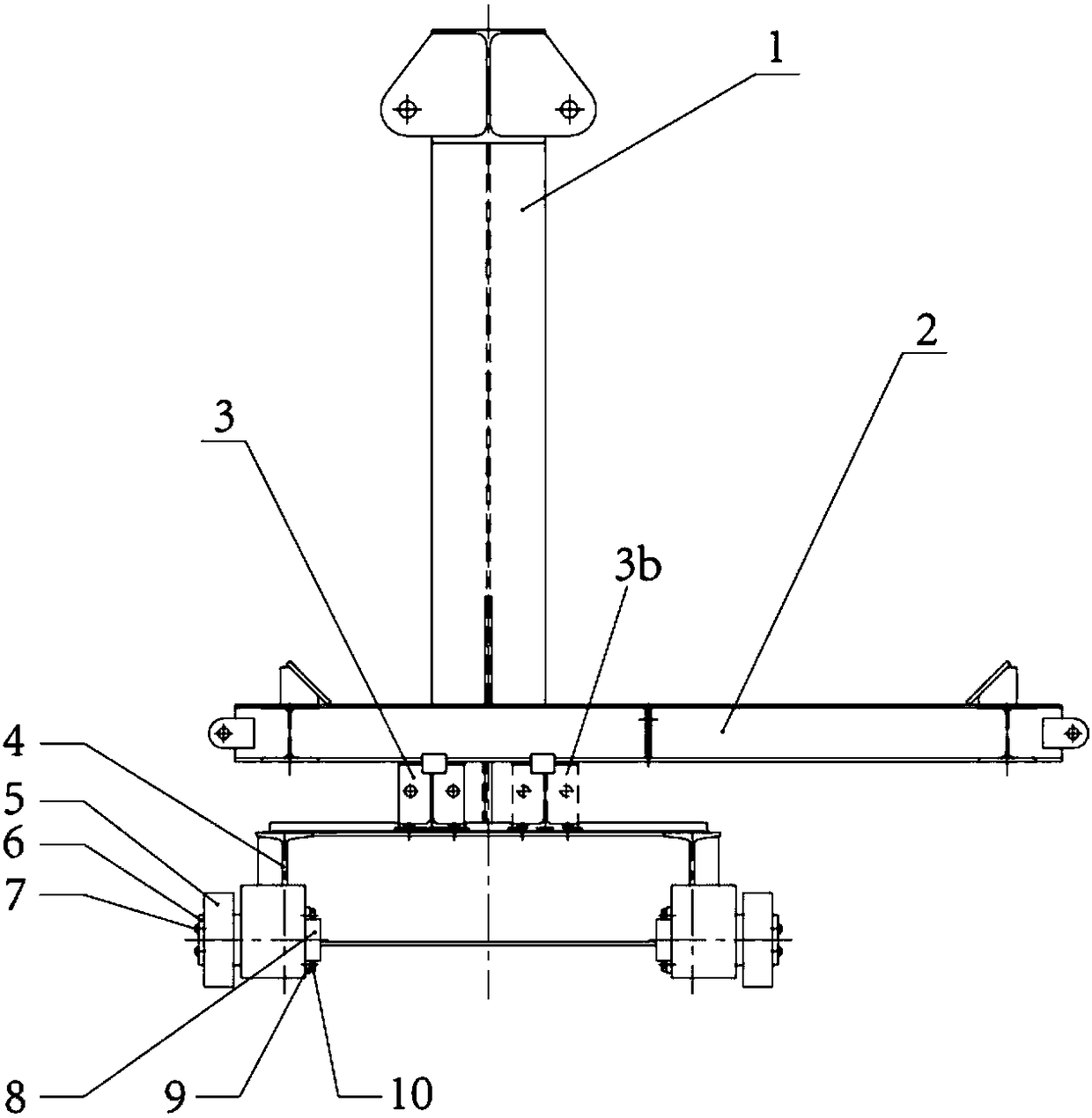

[0032] Such as Figure 2 to Figure 7 The shown rolling mill stand roll replacement device and its application schematic structure, the figure schematically shows the rolling mill right stand roll replacement process.

[0033] The main body of the rack roll replacement device provided by the present invention is a crane 300 that can be put in and out of the rolling mill, which includes a C-shaped right-angle frame 1, which includes a crossbeam 200, and the C-shaped opening of the right-angle frame 1 faces the tail of the crane . The right angle frame 1 is placed on the base 4, the base 4 is provided with a joist 3, and the joist 3 can move back and forth along the chute arranged on the base 4 in the horizontal direction (or it can also be set that the bracket 2 moves along the joist 3 The chute on the top moves back and forth along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com