Steam turbine governing valve redundancy control system and control method thereof

A redundant control and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of unrealized redundancy, safety, and hidden dangers of steam turbine control, so as to reduce unplanned downtime and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

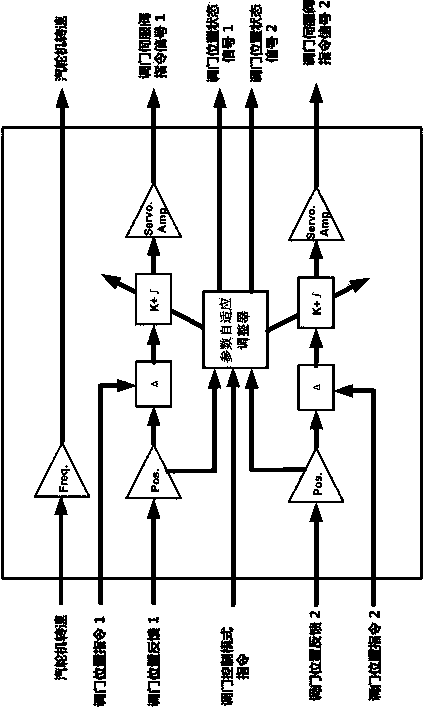

[0030] Example: A large steam turbine has two high-pressure valves. The steam turbine control system needs to adjust the opening of these two valves to achieve precise control of the important controlled variables, namely, the speed of the steam turbine, the pressure in front of the steam turbine and the power of the steam turbine. The entire working process from rushing to the rated speed to the initial load of the grid-connected belt to automatic load adjustment to shutdown.

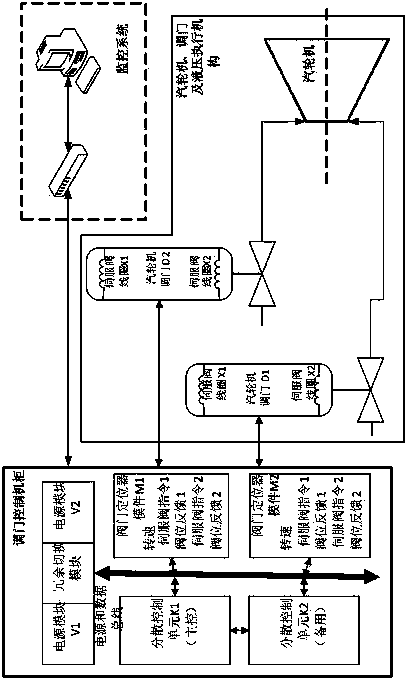

[0031] Such as figure 1 As shown, the redundant control system for steam turbine valve adjustment proposed by the present invention mainly includes a door adjustment control cabinet, a hydraulic actuator and a monitoring system.

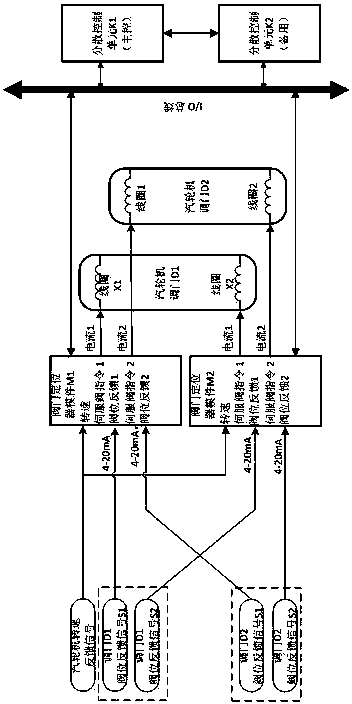

[0032] The door control cabinet is composed of a cabinet body, a redundant power supply, a redundant decentralized control unit, a redundant valve positioner module, etc.; the redundant power supply includes two power supply modules V1, V2 and a power supply redundancy switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com