Water-based mold release agent applied to aluminum alloy die casting and preparation method of water-based mold release agent

A technology for die-casting parts and release agent, which is applied in the field of water-based release agent for aluminum alloy die-casting and its preparation, can solve the problems of affecting the gloss and appearance of products, yellowing and blackening of organic residues, and reducing unplanned downtime. The effect of time, burden reduction, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

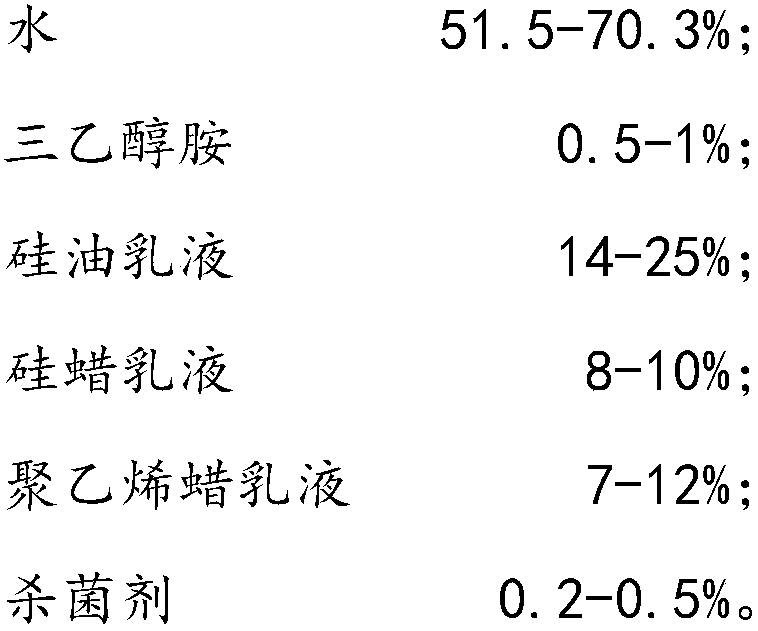

[0027] Add water 51.5%, triethanolamine 1%, Momentive silicone oil emulsion 334-50 25%, Wacker silicone wax emulsion WACKERE32 10%, BASF polyethylene wax emulsion WE-7 12%, BIT-20 fungicide 0.5%.

[0028] The preparation process is as follows: add triethanolamine and part of water into a clean container, add Momentive silicone oil emulsion 334-50, WACKER silicone wax emulsion WACKER E32 and BASF polyethylene wax emulsion WE-7 12% in sequence under high-speed stirring, and keep stirring After a period of time, add the remaining water and BIT-20 bactericide, and stir evenly at a low speed. The finished emulsion is white, uniform and fine, and it does not separate after centrifugation.

[0029] Among them, water is used as a solvent; triethanolamine is used as an antirust agent; Momentive silicone oil emulsion 334-50 plays the role of mold release and lubrication; WACKER silicone wax emulsion WACKER E32 plays the role of lubrication, assisting mold release and improving the stabil...

Embodiment 2

[0033] Others are the same as Example 1, except that the proportion is: add water 70.3%, triethanolamine 0.5%, Momentive silicone oil emulsion 334-50 14%, Wacker silicone wax emulsion WACKER E32 8%, BASF polyethylene wax emulsion WE -7 7%, BIT-20 fungicide 0.2%.

Embodiment 3

[0035] Others are the same as Example 1, except that the proportion is: add water 63%, triethanolamine 0.7%, Momentive silicone oil emulsion 334-50 18%, Wacker silicone wax emulsion WACKER E32 9%, BASF polyethylene wax emulsion WE -7 9%, BIT-20 fungicide 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com